High dam structure built on deep overburden of soil material shortage area

A technology of deep overburden and high dam, applied in infrastructure engineering, construction, water conservancy engineering, etc., can solve the problems of long transportation distance, increased investment, vegetation destruction, etc., to reduce consumption, improve construction speed, and reduce construction costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

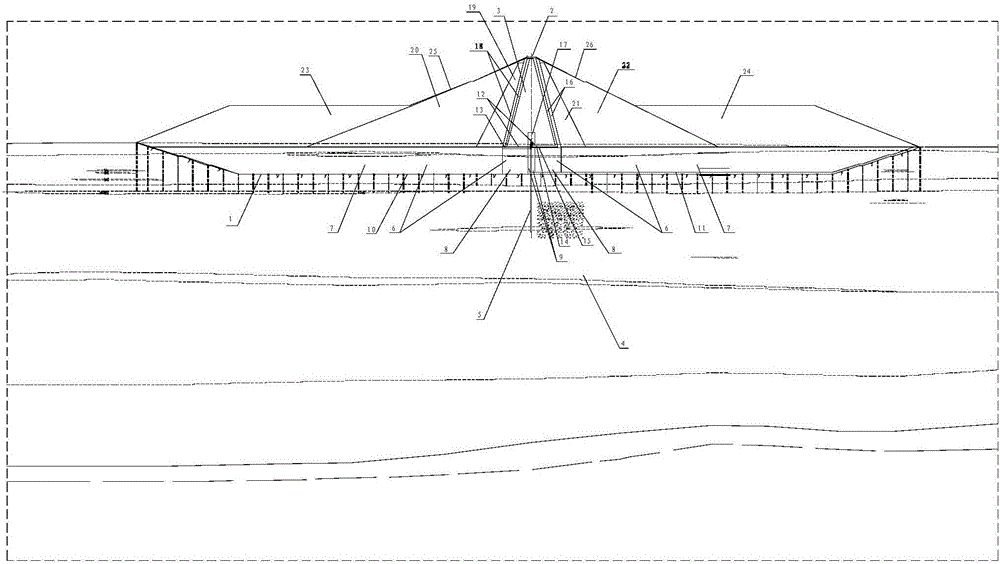

[0018] Such as figure 1 Shown is a high dam structure built on a deep overburden layer in a soil-deficient area provided by the present invention, which has fast construction speed, significantly reduced rare clay consumption, and significantly reduced construction cost. The high dam structure includes an excavation pit 1, a clay core wall 3 arranged in the dam body 2, and a concrete cut-off wall 5 arranged in the deep covering layer 4, and the high dam structure also includes a pile of foundation pits Stone backfill layer 6, the foundation pit rockfill backfill layer 6 is arranged in the excavated foundation pit 1, the clay core wall 3 is arranged on the top of the foundation pit rockfill backfill layer 6, the The concrete anti-seepage wall 5 vertically passes through the foundation pit rockfill backfill layer 6 and is embedded in the clay core wall 3, and the bottom of the excavated foundation pit 1 is reinforced with vibrating gravel piles. In the present application, a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com