A kind of hydrophobic stain-resistant functional solid acrylic matting resin

A technology of solid acrylic and matting resin, which is applied in the direction of antifouling/underwater coatings, powder coatings, paints containing biocides, etc., which can solve the problems of frequent cleaning of coatings, shortening the service life, etc., and achieve smoothness and hydrophobicity Improved stain resistance, extended service life, and avoiding frequent cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

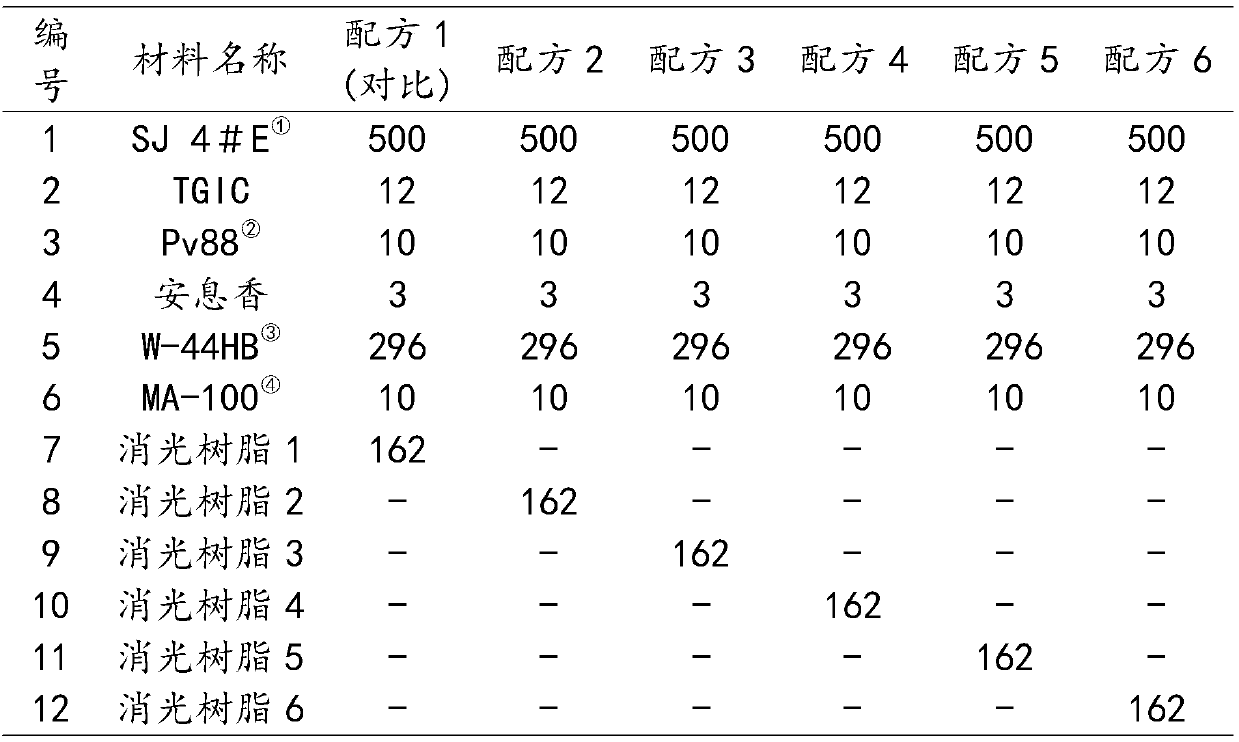

Examples

Embodiment 1

[0019] 40g of glycidyl methacrylate, 100g of methyl methacrylate, 50g of ethyl methacrylate, 10g of styrene, and 3.5g of phthaloyl peroxide were prepared as a dropwise mixed solution. Add 200g of xylene into a 1000ml three-necked flask and heat up and stir. After the solvent refluxes, start to add the mixed solution dropwise. After about 2.5-3h, the dropwise addition is completed, and the reflux reaction is continued for 2h. Add 0.5g of phthaloyl peroxide, and then Continue to reflux for 3h. Evaporate the solvent under reduced pressure, the temperature does not exceed 180°C, discharge the material while it is hot, cool, and coarsely pulverize to obtain 201g of epoxy acrylic matting resin 1, the glass transition temperature is 78.5°C, and the number average molecular weight is about 9055, the epoxy equivalent is 709 grams / equivalent.

Embodiment 2

[0021] Formulate 6g of trifluoroethyl acrylate, 44g of glycidyl methacrylate, 100g of methyl methacrylate, 40g of ethyl methacrylate, 10g of styrene, and 3.5g of phthaloyl peroxide The mixed solution was added dropwise. Add 200g of cyclohexanone into a 1000ml three-neck flask and heat up and stir. After the solvent refluxes, start to add the mixed solution dropwise. After about 2.5-3h, the dropwise addition is completed. Continue to reflux for 2h, and add 0.5g of phthaloyl peroxide. Continue to reflux reaction for 3h. Evaporate the solvent under reduced pressure, the temperature does not exceed 180°C, discharge the material while it is hot, cool, and coarsely pulverize to obtain 199g of epoxy acrylic matting resin 2, the glass transition temperature is 74°C, and the number average molecular weight is about 9550, the epoxy equivalent is 640 g / equivalent.

Embodiment 3

[0023] 10g of trifluoroethyl acrylate, 40g of glycidyl methacrylate, 100g of methyl methacrylate, 40g of ethyl methacrylate, 10g of styrene, 3.5g of phthaloyl peroxide The mixed solution was added dropwise. Add 200g of cyclohexanone into a 1000ml three-neck flask and heat up and stir. After the solvent refluxes, start to add the mixed solution dropwise. After about 2.5-3h, the dropwise addition is completed. Continue to reflux for 2h, and add 0.5g of phthaloyl peroxide. Continue to reflux reaction for 3h. Evaporate the solvent under reduced pressure, the temperature does not exceed 180°C, discharge the material while it is hot, cool, and coarsely pulverize to obtain 199g of epoxy acrylic matting resin 3, the glass transition temperature is 35°C, and the number average molecular weight is about 7500, the epoxy equivalent is 550 g / equivalent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com