Rolling device for oil containment boom for oil contamination on sea surface

An oil boom and oil pollution technology, which is used in the cleaning of open water surfaces, general water supply conservation, water conservancy projects, etc., can solve the problems of heavy oil boom, laborious operation, inconvenient operation, etc. Too much, the effect of improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

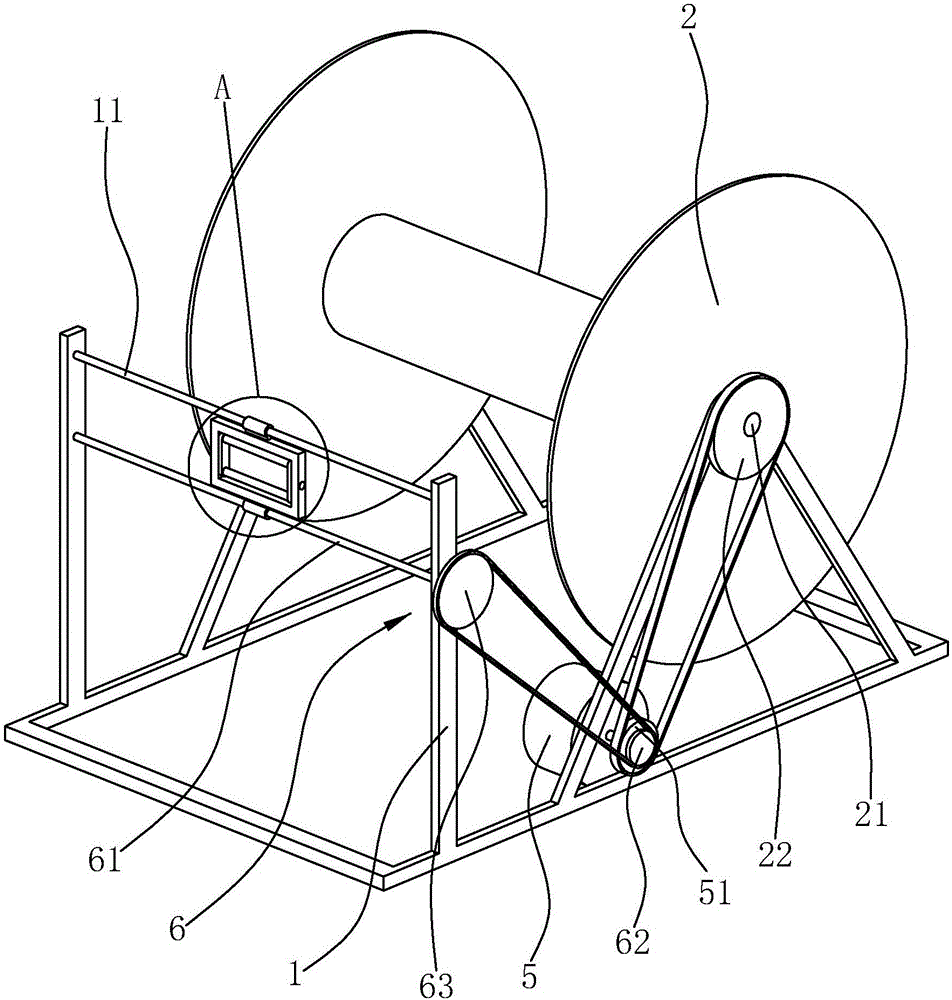

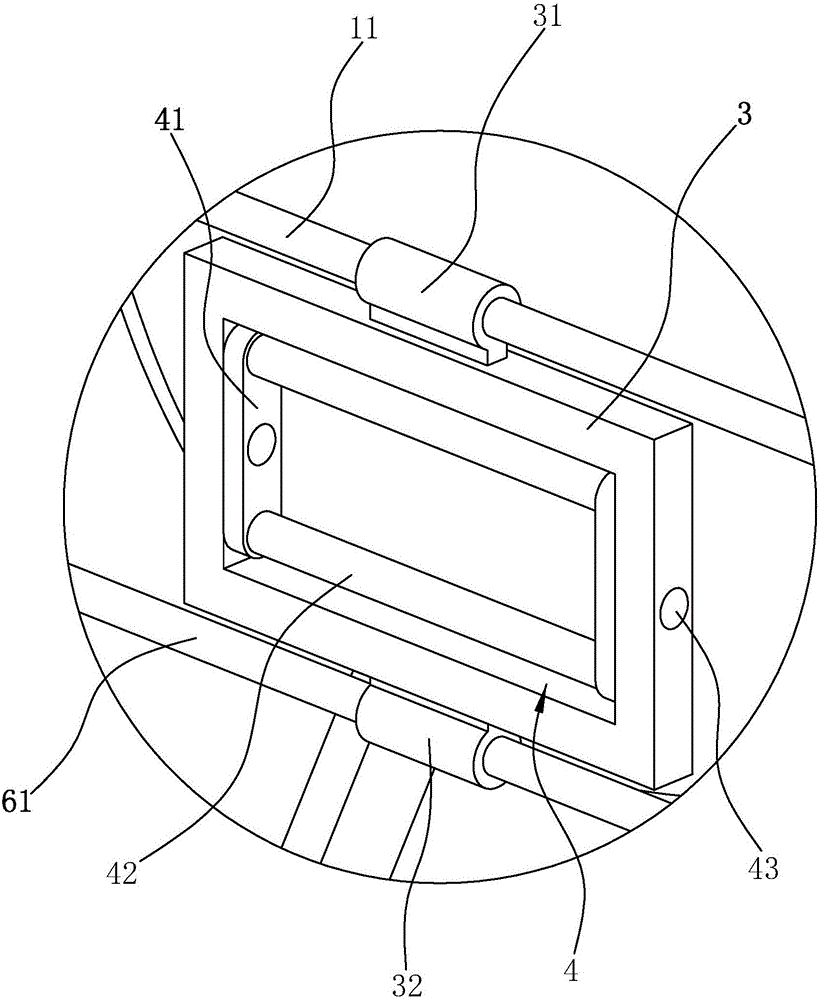

[0027] Such as Figure 1-4 As shown, a retracting device for an oil pollution oil boom on the sea surface includes a frame 1 on which a retracting drum 2 for retracting the oil boom 7 is rotatably connected, and the frame 1 is in front of the retracting drum 2 The traction frame 3 is slidably connected to the side along the retracting drum 2 in the axial direction, and the traction frame 3 is connected with an extruding frame 4 for the oil boom 7 to pass through. The frame 1 is provided with a driving motor capable of driving the retracting drum 2 to rotate. 5. A transmission member 6 capable of driving the traction frame 3 to reciprocate is provided between the driving motor 5 and the traction frame 3 .

[0028] Specifically, the oil boom 7 passes through the extruding frame 4 and is wound on the retracting drum 2, and the driving motor 5 drives the retracting drum 2 to rotate, thereby continuously retracting the oil boom 7. During the retracting process, The driving motor 5...

Embodiment 2

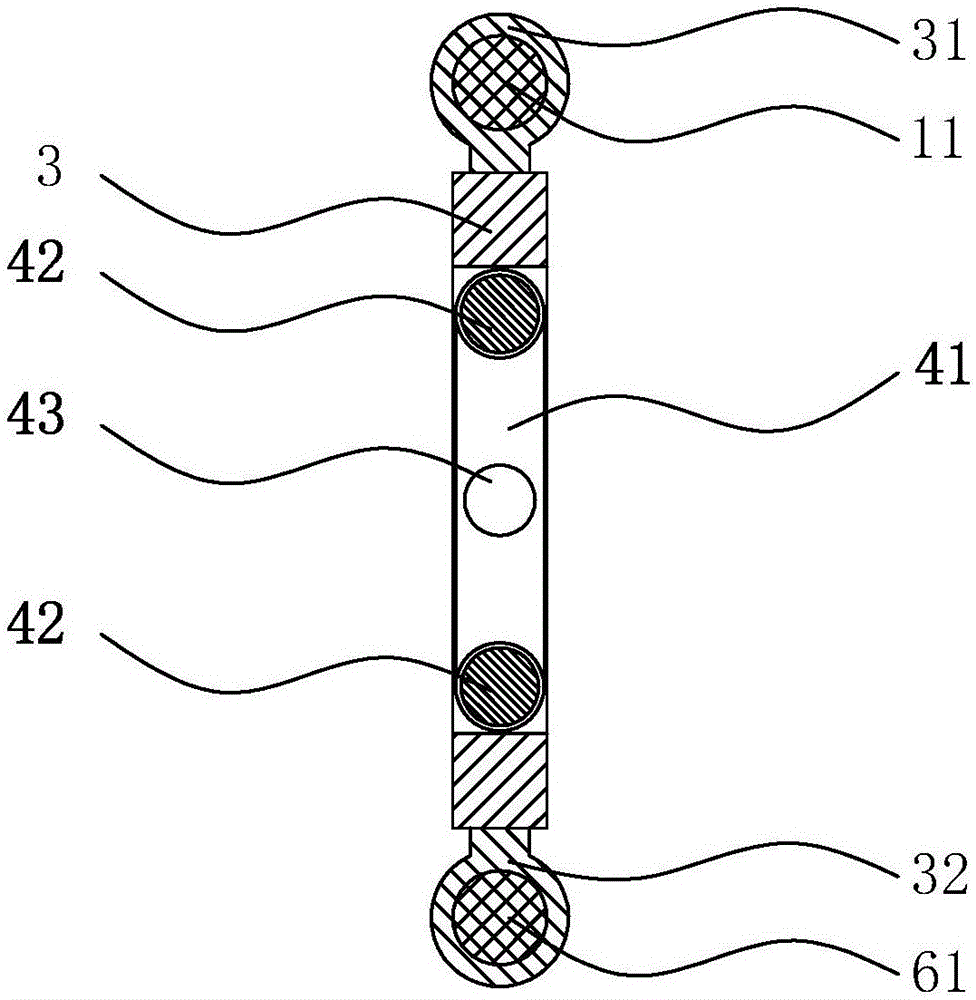

[0034] refer to Figure 5-7 , the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the inner edges of the left and right sides of the traction frame 3 respectively have a limiter 34, and the outer edges of the left and right sides of the extrusion frame 4 each have a stopper 34. Limiting part 2 44, two connecting columns 43 are provided with torsion springs 8, and the limiting part 1 34 and limiting part 2 44 located on one side are respectively located at the upper and lower ends of the connecting column 43 on the same side. And the two spring arms of one of the torsion springs 8 are respectively against the rear side of the first 34 of the limiting member and the second 44 of the limiting member and the rear side of the second 44 of the limiting member on the same side. Position piece one 34 and limit piece two 44 are respectively located at the upper and lower ends of the connecting column 43 on the same side, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com