An Unbalanced Injection Mold

An injection molding, non-equilibrium technology, which is applied in the field of non-equilibrium injection molding molds, can solve the problems of preparing gradient functional materials, not being able to use injection molding molds, and restricting the application of injection molding molds, so as to expand the scope of application and control the shape precisely and effectively , to overcome the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

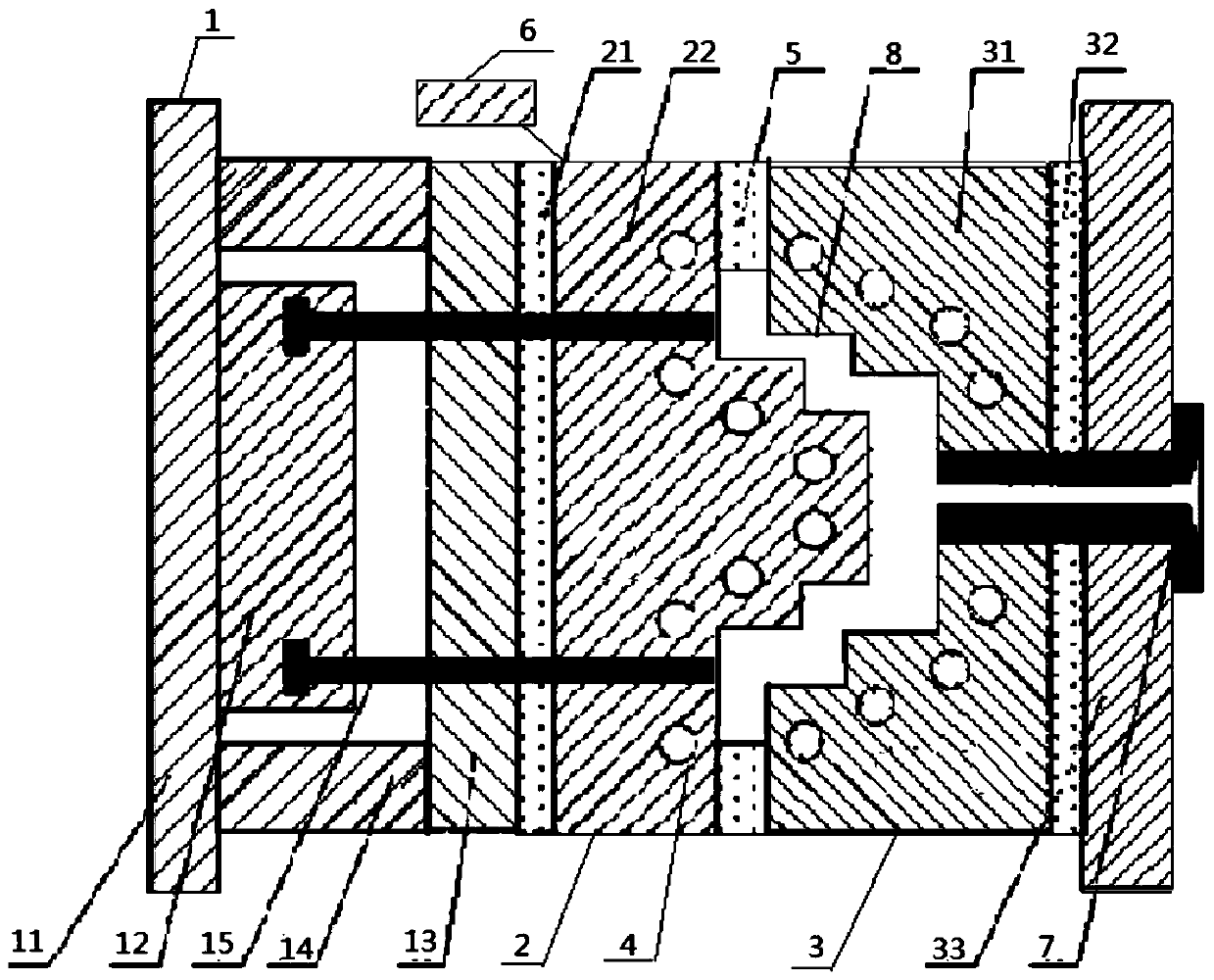

[0054] The unbalanced injection molding mold includes a mold clamping system 1, a movable mold part 2, and a fixed mold part 3 from left to right. The mold clamping system 1 includes a movable mold seat plate 11 from left to right, and a Top plate 12, support formwork 14, movable formwork backing plate 13 and thimble 15 connected to support formwork 14; movable formwork part 2 comprises first heat insulating partition 21, movable formwork plate 22 successively from left to right; fixed formwork part 3 from left to right The right side includes a fixed template 31, a third heat insulating partition 32, and a fixed mold seat plate 33 in sequence; Connected mouth 7.

[0055] The movable formwork 22 is made of high-strength, high-toughness and high-heat-transfer aluminum nitride ceramics, the second insulation partition 5 with the same thickness as the finished product is made of polybendazole, and the first insulation partition 21 is made of basalt fiber composite material.

[0...

Embodiment 2

[0059] The unbalanced injection molding mold includes a mold clamping system 1, a movable mold part 2, and a fixed mold part 3 from left to right. The mold clamping system 1 includes a movable mold seat plate 11 from left to right, and a Top plate 12, support formwork 14, movable formwork backing plate 13 and thimble 15 connected to support formwork 14; movable formwork part 2 comprises first heat insulating partition 21, movable formwork plate 22 successively from left to right; fixed formwork part 3 from left to right The right side includes a fixed template 31, a third heat insulating partition 32, and a fixed mold seat plate 33 in sequence; Connected mouth 7.

[0060] The movable template 22 is made of high-strength, high-toughness and high-heat-transfer silicon carbide ceramics, and the second heat-insulating partition 5 with the same thickness as the product is made of zirconia ceramics, and is made of an integrated structure with the movable template 22. The first therm...

Embodiment 3

[0064] The unbalanced injection molding mold includes a mold clamping system 1, a movable mold part 2, and a fixed mold part 3 from left to right. The mold clamping system 1 includes a movable mold seat plate 11 from left to right, and a Top plate 12, support formwork 14, movable formwork backing plate 13 and thimble 15 connected to support formwork 14; movable formwork part 2 comprises first heat insulating partition 21, movable formwork plate 22 successively from left to right; fixed formwork part 3 from left to right The right side includes a fixed template 31, a third heat insulating partition 32, and a fixed mold seat plate 33 in turn; Connected mouth 7.

[0065] The movable template 22 is made of high-strength, high-toughness and high-heat transfer Al2O3 ceramics, and the second heat-insulating partition 5 and the first heat-insulating partition 21 with the same thickness as the product are made of high-strength, high-toughness and heat-insulating zirconia ceramics, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com