A treatment method and device for high-concentration organic waste gas

A technology of organic waste gas and treatment method, which is applied in separation methods, combustion methods, chemical instruments and methods, etc., can solve the problems of inability to recover hydrocarbon substances, failure to achieve the purpose of treatment, waste of hydrocarbon resources, etc., so as to achieve no unsafe hazards. , Enhance stability and safety, and ensure the effect of safe combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

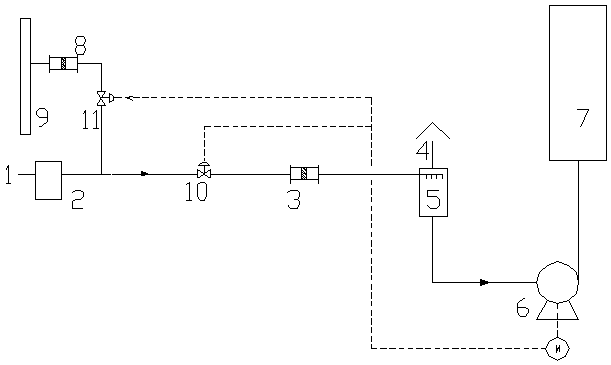

[0032] Using the present invention figure 1 The process is to deal with the fugitive oil and gas of a small crane tube train gasoline loading in a refinery, and the emission of fugitive gas is 300m 3 / h, the total hydrocarbon concentration of the gas is 300-413g / m 3 , the fugitive gas is absorbed by regular three-line gas oil, and the absorbed liquid-gas ratio is 100L / m 3 , the absorption temperature is 35℃, and the absorption pressure is 100kPa, so that the total hydrocarbon concentration of the exhaust gas after absorption is 25000-30000mg / m 3 about. The selected air volume is 90000m 3 The heating furnace above / h incinerates the gas after diesel absorption, and the total hydrocarbon concentration of the gas after the organic waste gas is mixed with the air distribution air is less than 100mg / m3 3 , the oxygen consumption of oxidized pollutants is less than 0.028%. After being absorbed and incinerated, the fugitive oil and gas from gasoline loading can reach the standar...

Embodiment 2

[0034] Using the present invention figure 1 The process is to deal with the fugitive oil and gas of a large crane tube train in a refinery, and the emission of fugitive gas is 500m 3 / h, the total hydrocarbon concentration of the gas is 200-450g / m 3 , the fugitive gas is absorbed by regular three-line gas oil, and the absorbed liquid-gas ratio is 100L / m 3 , the absorption temperature is 35℃, and the absorption pressure is 150kPa, so that the total hydrocarbon concentration of the exhaust gas after absorption is 20000-26000mg / m 3 . The selected air volume is 130000m 3 The heating furnace above / h incinerates the gas after diesel absorption, and the total hydrocarbon concentration of the gas after the organic waste gas is mixed with the air distribution air is less than 100mg / m3 3 , the oxygen consumption of oxidized pollutants is less than 0.028%. After being absorbed and incinerated, the fugitive oil and gas from gasoline loading can reach the standard emission, and the c...

Embodiment 3

[0036] Using the present invention figure 1 The process is to deal with the fugitive oil and gas of a large crane tube train in a refinery, and the emission of fugitive gas is 500m 3 / h, the total hydrocarbon concentration of the gas is 200-450g / m 3 , the fugitive gas is absorbed by the usual three-line gas oil, and the absorbed liquid-gas ratio is 80L / m 3 , the absorption temperature is 10 °C, and the absorption pressure is 80 kPa, so that the total hydrocarbon concentration of the exhaust gas after absorption is 15000-20000 mg / m 3 . The selected air volume is 100000Nm 3 The heating furnace above / h incinerates the gas after diesel absorption, and the total hydrocarbon concentration of the gas after the organic waste gas is mixed with the air distribution air is less than 100mg / m3 3 , the oxygen consumption of oxidized pollutants is less than 0.028%. After being absorbed and incinerated, the fugitive oil and gas from gasoline loading can reach the standard emission, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com