Circulating medium impurity-removal recovering and cleaning system

A technology of circulating medium and medium, applied in the direction of magnetic separation, solid separation, dispersed particle separation, etc., can solve the problems of process pipeline blockage, process fluctuation, energy and equipment parts loss, etc., to reduce seal leakage rate and process fluctuation. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be explained in more detail by the following examples, the present invention is not limited to the following examples, the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention;

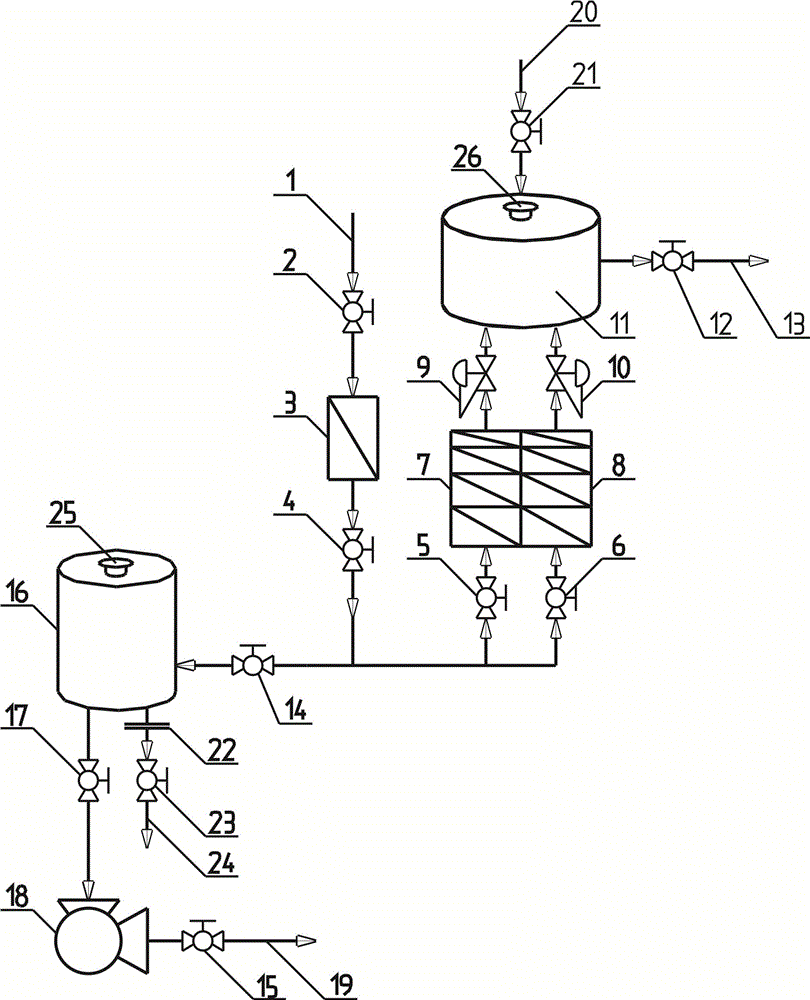

[0022] combined with figure 1 The circulating medium impurity removal recovery and cleaning system includes a circulating medium inlet 1, an electromagnetic filter grid 3, a classification filter A7, a classification filter B8, a sedimentation buffer tank 11, a circulating medium outlet 13, a sedimentation separation tank 16, and a medium recovery Pump 18, recovery medium outlet 19, recovery medium and impurity flushing inlet 20, impurity discharge flange 22 and impurity discharge port 24, the inlet of the electromagnetic filter grid 3 is connected to the circulation medium inlet 1, the outlet of the electromagnetic filter grid 3 and The coarse filtration end of the classification filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com