A liquid metal circuit breaker

A liquid metal and circuit breaker technology, applied in circuits, electrical components, electric switches, etc., can solve the problems of low economic cost, insufficient rated current capacity, and failure to meet actual needs, etc., and achieve the effect of strong rated current capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

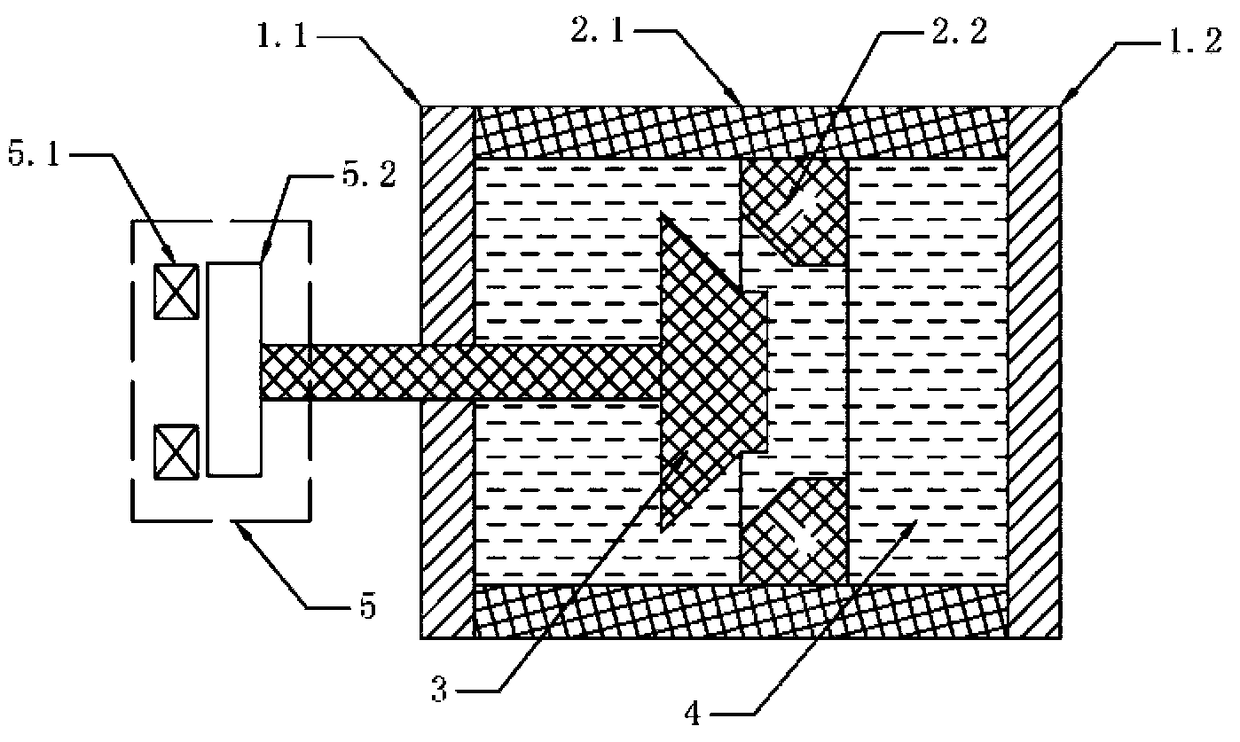

[0025] Such as figure 1 As shown, the operating mechanism 5 is located on the right side of the closed cavity, and the operating mechanism 5 pulls the insulating cutting board 3 to move to the right, making it contact with the insulating partition 2.2 and maintain pressure.

Embodiment 2

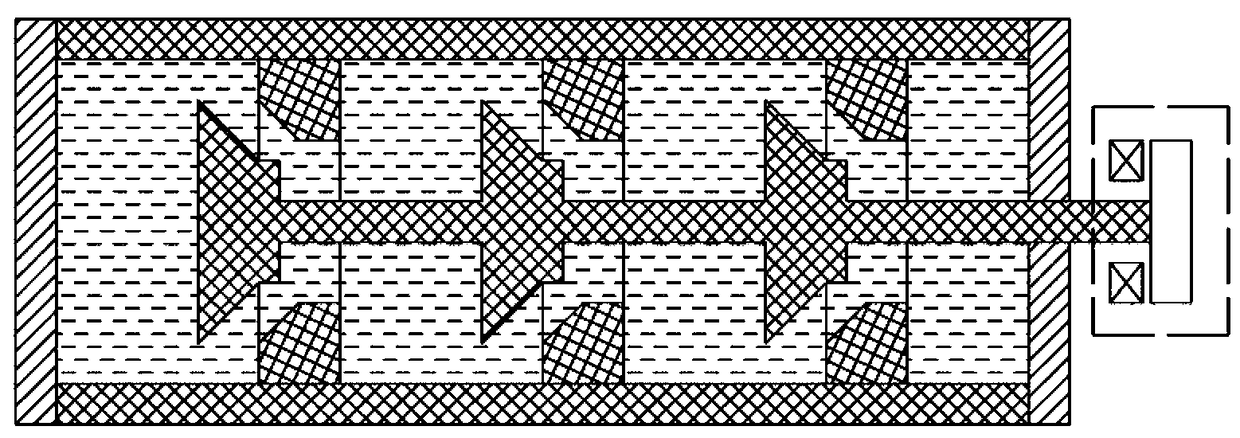

[0027] Such as figure 2 As shown, the operating mechanism 5 is located on the left side of the closed cavity, and the operating mechanism 5 pulls the insulating cutting board 3 to move to the left, making it contact with the insulating partition 2.2 and maintain pressure.

Embodiment 3

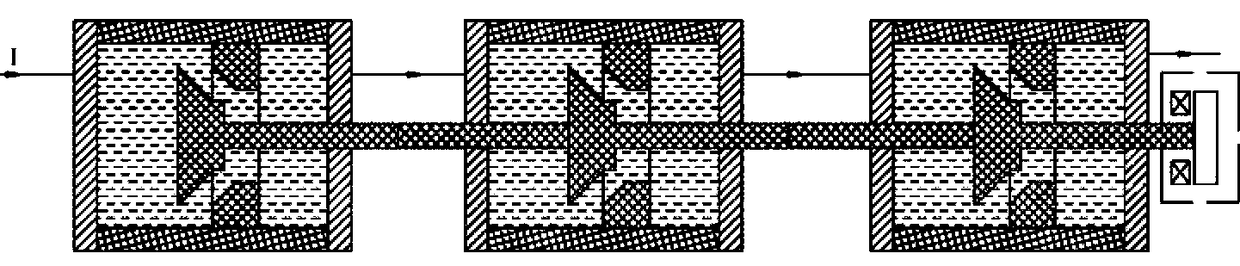

[0029] Such as image 3 As shown, a series form of liquid metal circuit breaker modules, the closed cavity has multiple and independent of each other, the insulating cutting board 3 in each closed cavity is connected to the operating mechanism 5 through the same pull rod, so that the Multiple closed cavities are connected in series.

[0030] In fact, using liquid metal circuit breaker modules for parallel connection also belongs to the category covered by this invention patent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com