Worm wheel- worm lead screw transmission type two-way stretch test machine

A two-way stretching, worm gear technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of inability to test mechanical properties, high tensile speed, sample yield force and deformation Small and other problems, to avoid accidental breakage of the sample, reduce the transmission distance, and achieve the effect of accurate material mechanical performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

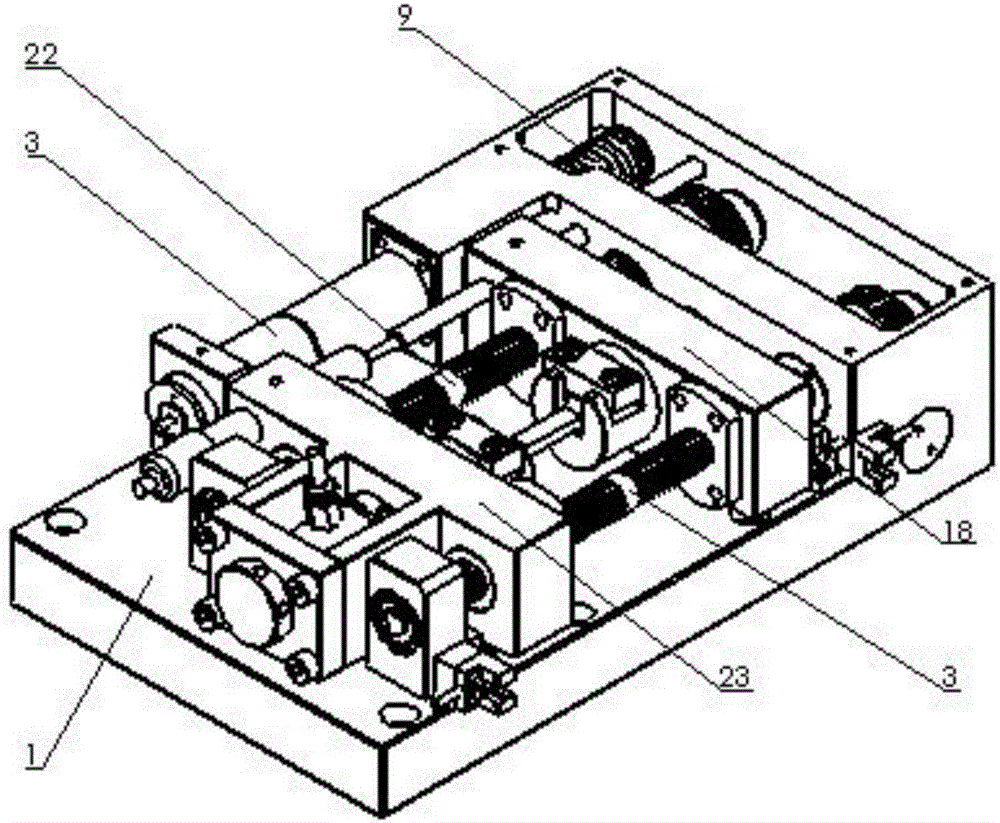

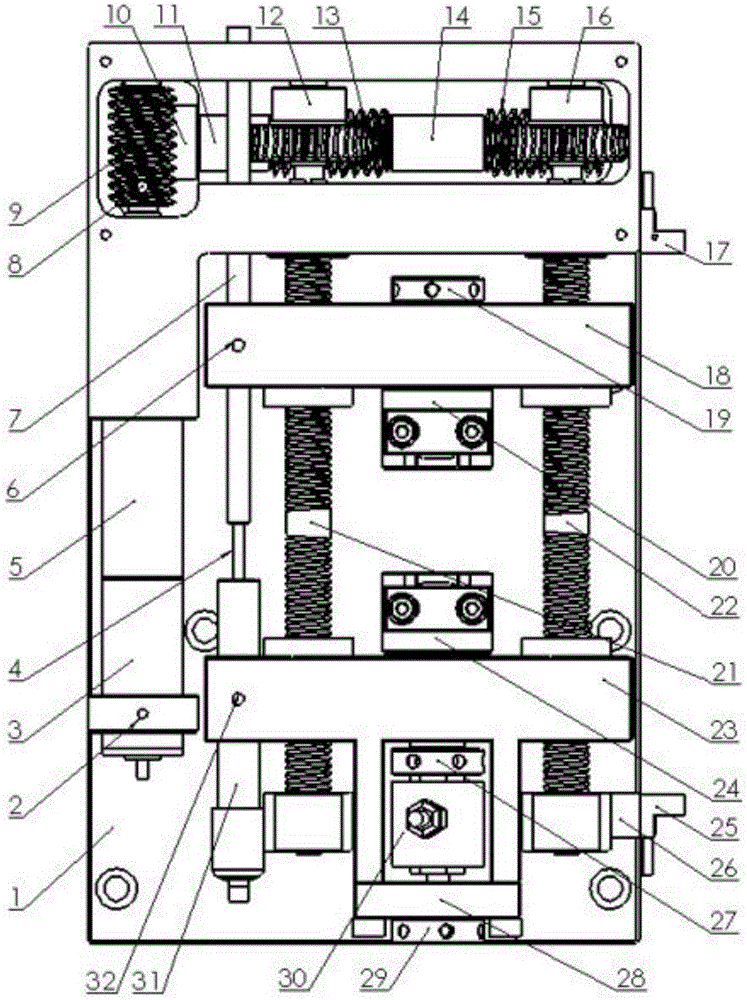

[0049] Such as figure 1 and figure 2 As shown, in this embodiment, a worm gear screw drive type bidirectional tensile testing machine is composed of a frame, a loading power module, a sensor module and a clamping module:

[0050] A loading power module, a sensor module and a clamping module are arranged on the frame 1;

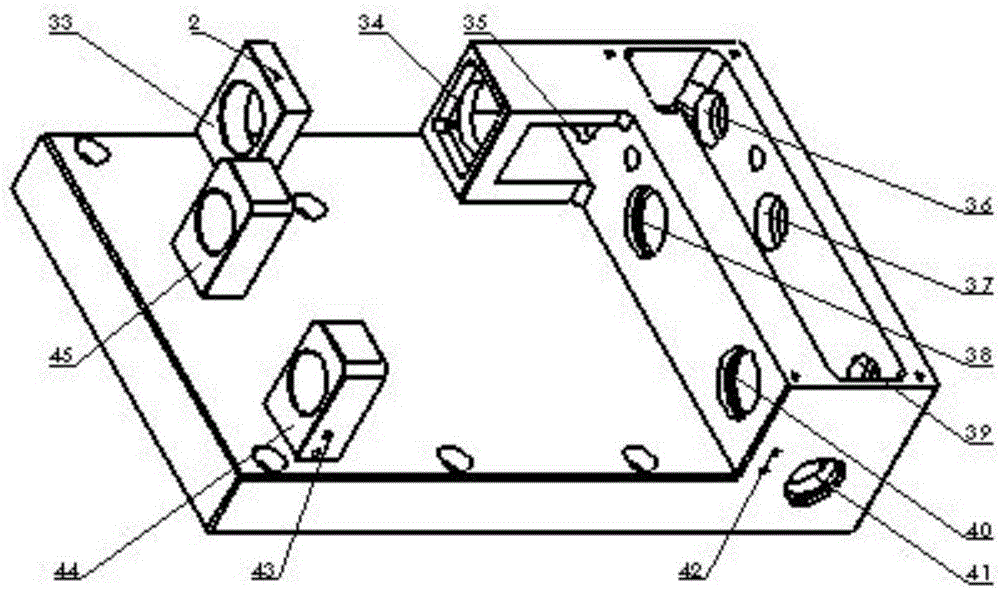

[0051] Such as image 3 and Figure 4 As shown, the frame is processed from an integral structure, including: motor seat 33, motor fixing threaded hole 2, motor flange seat 34, first bearing seat 35, second bearing seat 36, third bearing seat 37, fourth Bearing seat 38, fifth bearing seat 39, sixth bearing seat 40, seventh bearing seat 41, first travel switch fixing threaded hole 42, second travel switch fixing threaded hole 43, eighth bearing seat 44, ninth bearing seat 45. The tenth bearing seat 46;

[0052] The loading power module includes: motor 3, gearbox 5, motor flange 47, connector 49, motor connecting shaft 50, worm shaft 64, first worm 9, firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com