Lubricating mechanism oil nozzle structure

A technology for lubricating mechanism and oil injection port, which is applied in lubricating parts, engine lubrication, mechanical equipment, etc. It can solve the problems of large losses, achieve good oil injection effect and protect the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

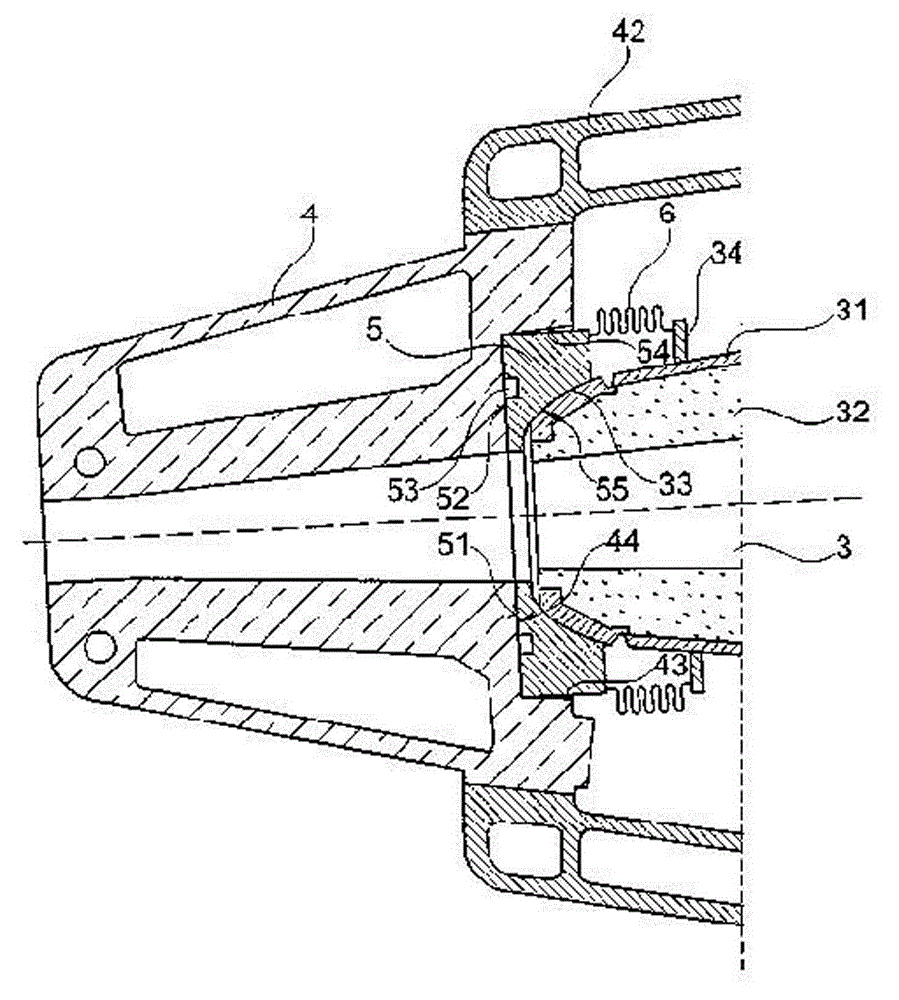

[0015] A lubricating mechanism oil injection port structure of the present invention includes an inner oil pipe 3, a metal sleeve 31, a ceramic pipe 32, a connecting plate 34, a nozzle 4, a casing 42, a connecting surface 44, a connecting block 5, a contact surface 51, and a sealing surface 52 , an annular groove 53, a connecting groove 54, an arc surface 55 and a flexible oil sealing sleeve 6, characterized in that: the inner oil pipe 3 includes a ceramic pipe 32, and a metal sleeve 31 is arranged outside the ceramic pipe 32, and the metal sleeve 31 passes through The arc surface 55 is provided with a connecting block 5, and the connecting block 5 is provided in the connecting groove 54 of the nozzle 4; between the connecting block 5 and the connecting groove 54 is a sealing surface 52; the metal sleeve 31 is provided with a connecting plate 34, which is connected A flexible oil sealing sleeve 6 is arranged between the plate 34 and the connecting block 5 .

[0016] As a prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com