Overflow high-temperature cut-off valve

A shut-off valve, high temperature technology, applied in the field of balancing valves, can solve the problems of "misoperation, gas leakage, corrosion of components, etc., and achieve the effects of being beneficial to reliability, increasing the operating range, and enhancing the specific pressure of the seal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

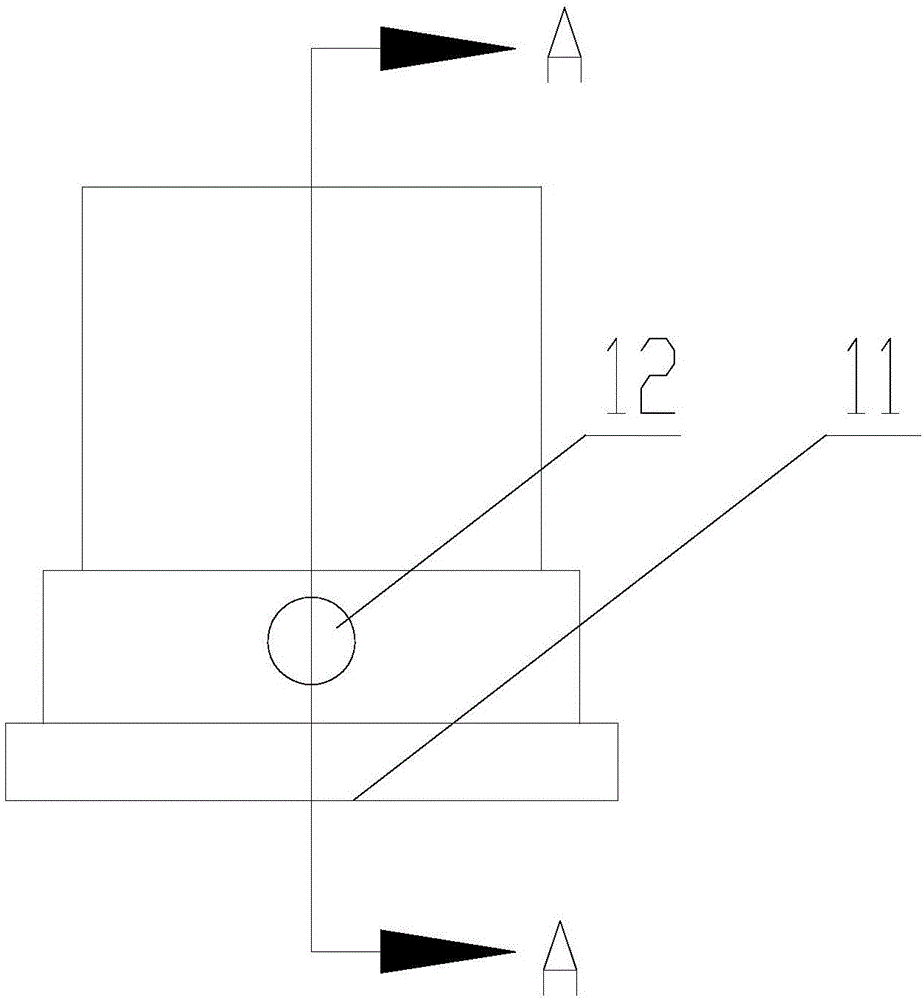

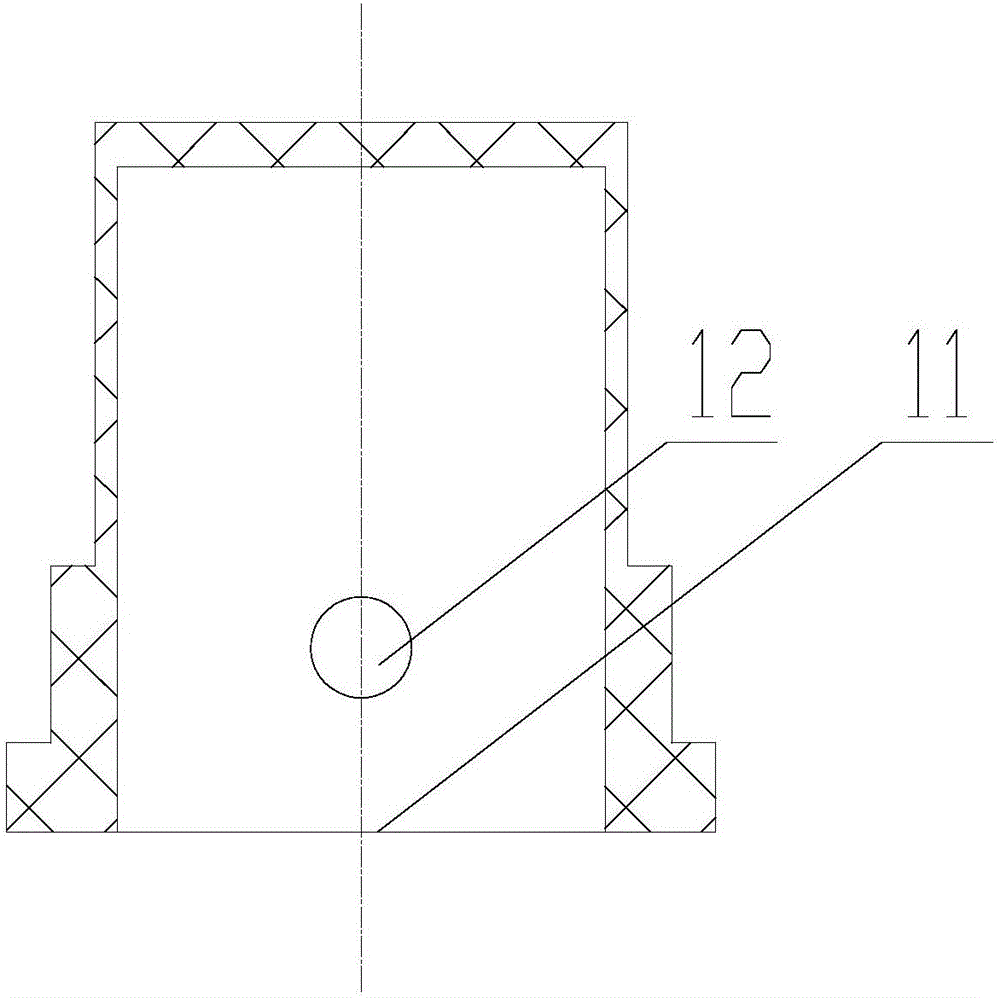

[0041] This embodiment is an overcurrent high temperature cut-off valve, combined with figure 1 , consisting of a filter mechanism 1, a high temperature protection mechanism, an overcurrent protection mechanism and a valve cover 10, the filter mechanism 1, a high temperature protection mechanism, and an overcurrent protection mechanism are installed in the valve cover 10 in sequence, and the high temperature protection mechanism consists of a bracket 2, a spring-3 , a temperature sensing body 4, and a head 5, the bracket 2 is located between the filter mechanism 1 and the head 5, the spring one 3 is set on the bracket 2, and is in a compressed state between the bracket 2 and the head 5 during installation, The temperature sensing body 4 is located on the end of the bracket 2 facing the head 5; the overcurrent protection mechanism is composed of a spring 2 7, a valve disc 8 and a protection frame 9, the valve disc 8 is installed in the protection frame 9, and the spring 2 7 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com