Fuel gas shutoff solenoid valve controller

A technology for cutting off solenoid and valve controller, applied in valve details, valve device, valve operation/release device, etc., which can solve the problem that the gas supply solenoid valve cannot be automatically shut off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

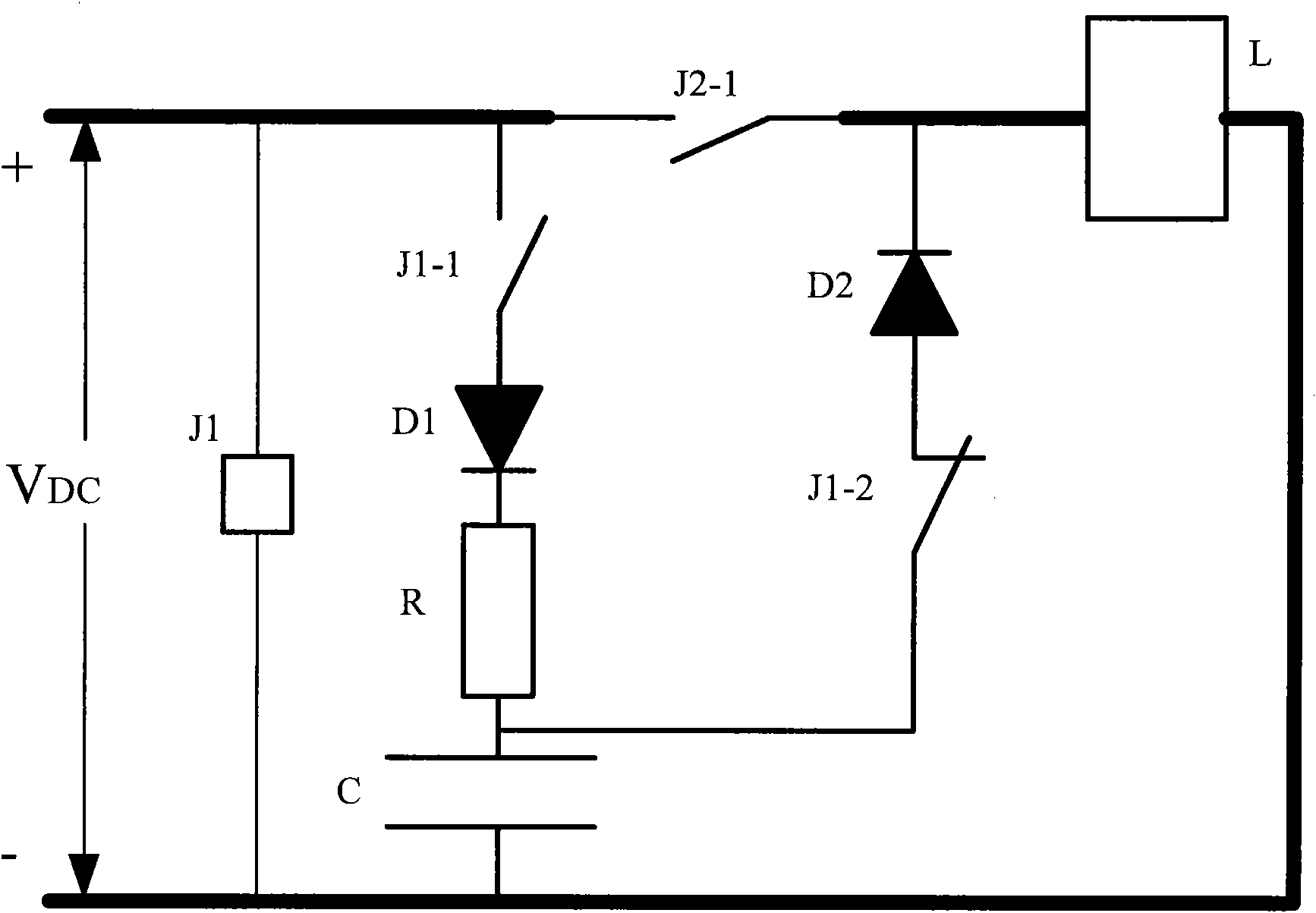

[0015] The gas cut-off solenoid valve controller is shown in the figure, DC power supply V DC It is converted from mains electricity; the coil J1 of the relay is connected to the DC power supply V DC Two poles; the cathode of the capacitor C is grounded (the figure is the DC power supply V DC Negative pole), the anode is connected to the DC power supply V DC Positive pole; one end of the solenoid valve L used as a gas supply switch is grounded, and the other end is connected to the DC power supply V through the alarm switch J2-1 DC Positive pole, the alarm switch J2-1 is controlled by an external alarm, which is also powered by the mains, and the alarm switch J2-1 is in the disconnected state under normal working conditions; the node between the solenoid valve L and the alarm switch J2-1 passes through a The branch formed by the normally closed contact J1-2 of the relay and the diode connected in series is connected to the anode of the capacitor C.

[0016] The operator ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com