A mechanism that changes swing friction into rotational friction

A technology of rotating friction and swinging friction, applied in the direction of ball and roller bearings, which can solve the problems of bearing wear and accumulation of wear debris, wear solid lubrication debris, etc., and achieve the effect of prolonging service life and improving speed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and example the specific embodiment of the present invention is described in further detail:

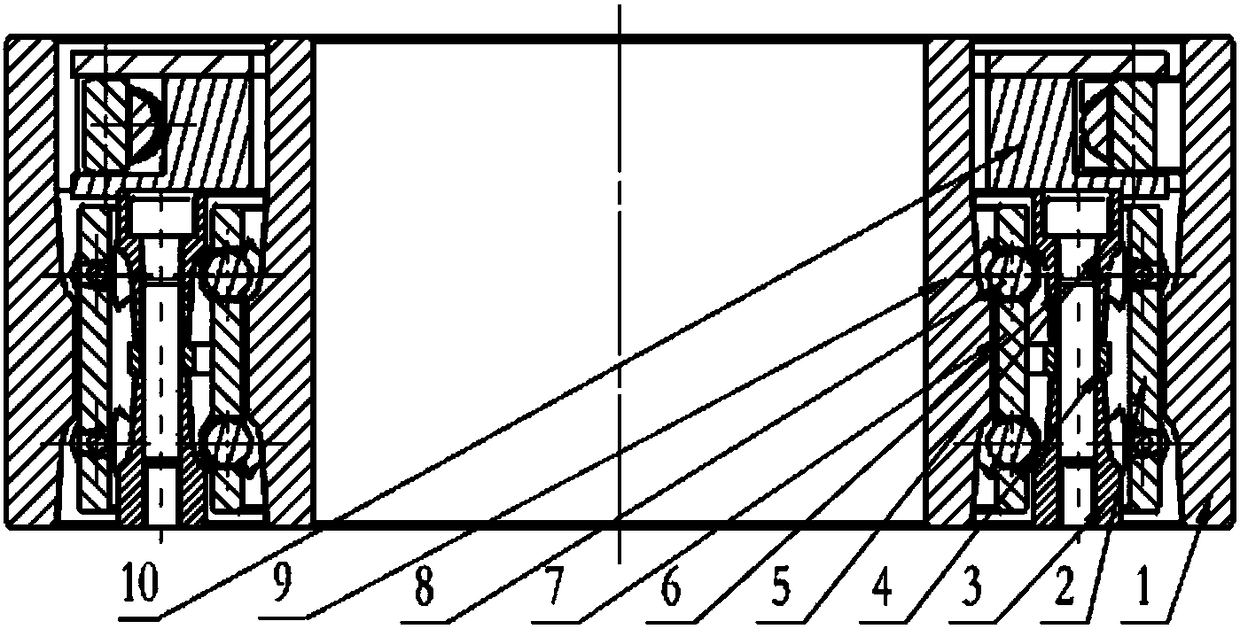

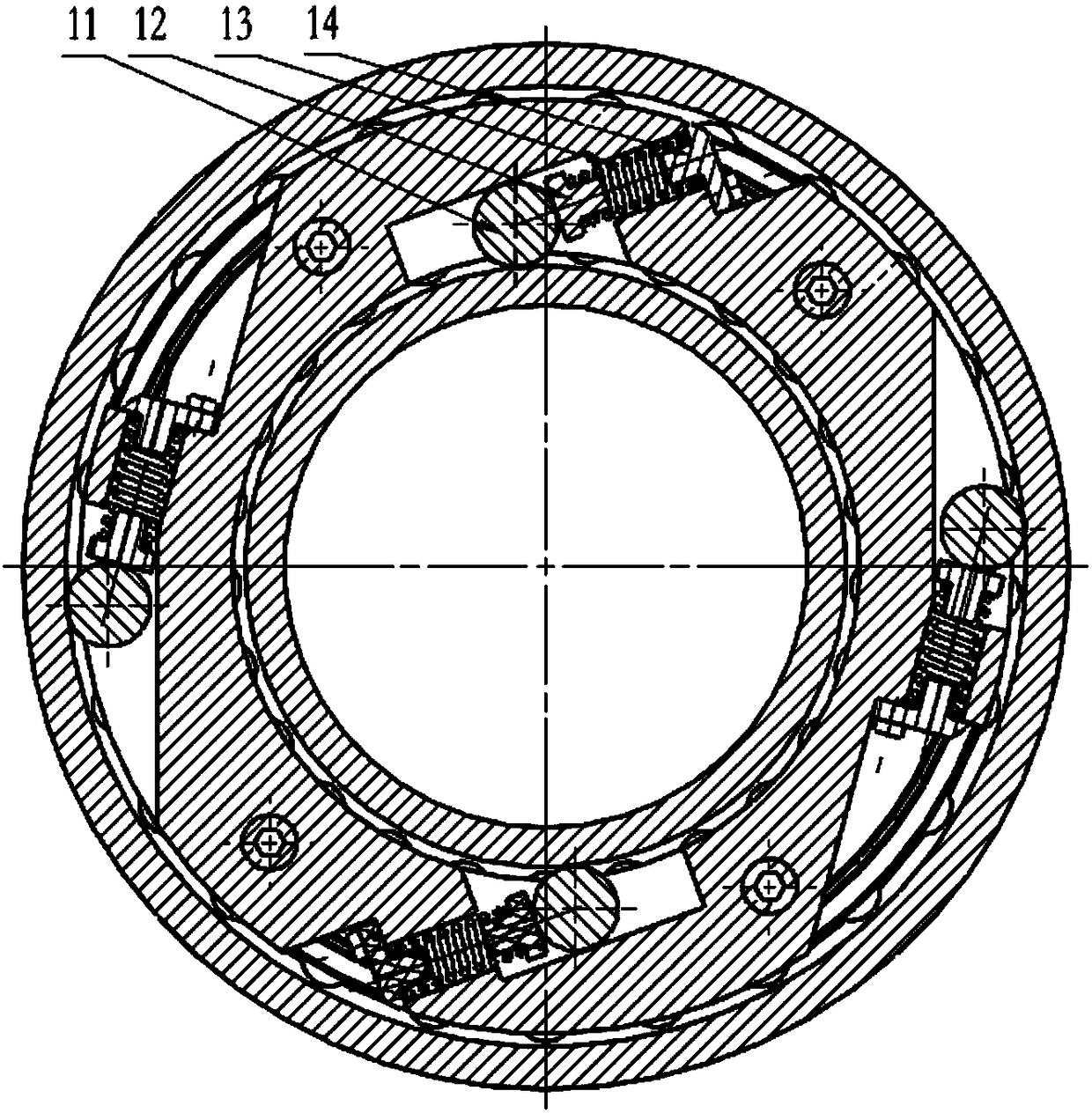

[0011] figure 1 It is the front cross-sectional view of the invented mechanism of swinging friction into rotating friction, figure 2 Its top sectional view. The size of the outer ring 1 is Ф160mm in outer diameter, Ф142mm in inner diameter, 64mm in width, the distance between the two grooves is 22mm, the radius of curvature of the groove is 4.2mm, the material is 9Cr18, and the quenching HRC is ≥ 56; the outer ball cage 2 The outer diameter is Ф141mm, the inner diameter is Ф133mm, and the width is 40mm. The material is polyimide containing molybdenum disulfide. There are 52 holes of Ф8.5mm in double rows, and the distance between the two rows of holes is 22mm. The width is 20mm, the material is 9Cr18, quenching HRC≥56; the outer diameter of the middle pretension ring 4 is Ф128mm, the inner diameter is Ф111mm, the width is 4mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com