Drilling method of second-spudding horizontal well

A horizontal well and drilling technology, which is applied to wellbore/well components, wellbore/well valve devices, and production fluids, etc., can solve the problems of long reservoir stimulation cycle, inability to workover, long drilling and completion cycle, etc. Achieve the effect of ensuring smooth connection, saving gas test costs, and saving gas test cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

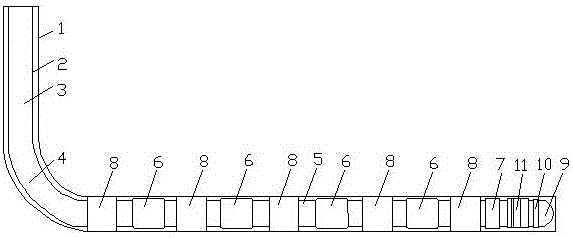

[0050] A method for drilling two horizontal wells, comprising the steps of:

[0051] a. The first drilling is completed with a drill bit with an outer diameter of 346mm, and then the casing 1 with an outer diameter of 273mm is run in to complete the cementing;

[0052] b. Use a drill bit with an outer diameter of 222mm to complete the drilling of the second open vertical well section, and then trip out; then use a drill bit with an outer diameter of 215.9mm to complete the drilling of the second open well section and the second open horizontal section; Afterwards, through the well;

[0053] c. After the well is opened, run into the integrated cementing and completion pipe string device of the second open horizontal well;

[0054] d. Flush the surface cementing pipeline, inject clean water and cement slurry to lead the slurry, and then inject the cement slurry into the tail rotor after an interval of t1;

[0055] e. After the interval time t2, inject 4m in sequence 3 clean w...

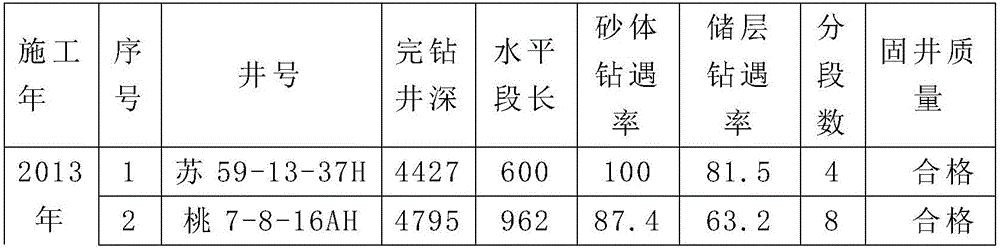

Embodiment 2

[0061] A method for drilling two horizontal wells, comprising the steps of:

[0062] a. The first drilling is completed with a drill bit with an outer diameter of 346mm, and then the casing 1 with an outer diameter of 273mm is run in to complete the cementing;

[0063] b. Use a drill bit with an outer diameter of 222mm to complete the drilling of the second open vertical well section, and then trip out; then use a drill bit with an outer diameter of 215.9mm to complete the drilling of the second open well section and the second open horizontal section; Afterwards, through the well;

[0064] c. After the well is opened, run into the integrated cementing and completion pipe string device of the second open horizontal well;

[0065] d. Flush the surface cementing pipeline, inject clean water and cement slurry to lead the slurry, and then inject the cement slurry into the tail rotor after an interval of t1;

[0066] e. After the interval time t2, inject 4.5m in sequence 3 clean...

Embodiment 3

[0073] A method for drilling two horizontal wells, comprising the steps of:

[0074] a. The first drilling is completed with a drill bit with an outer diameter of 346mm, and then the casing 1 with an outer diameter of 273mm is run in to complete the cementing;

[0075] b. Use a drill bit with an outer diameter of 222mm to complete the drilling of the second open vertical well section, and then trip out; then use a drill bit with an outer diameter of 215.9mm to complete the drilling of the second open well section and the second open horizontal section; Afterwards, through the well;

[0076] c. After the well is opened, run into the integrated cementing and completion pipe string device of the second open horizontal well;

[0077] d. Flush the surface cementing pipeline, inject clean water and cement slurry to lead the slurry, and then inject the cement slurry into the tail rotor after an interval of t1;

[0078] e. After the interval time t2, inject 5m in sequence 3 clean w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com