Light roasting pressing ball for converter steelmaking and preparation method of light roasting pressing ball

A converter steelmaking and light sintering technology, which is applied in the manufacture of converters and other directions, can solve problems such as harsh production environment, and achieve the effects of stable slag composition, easy operation and stable composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

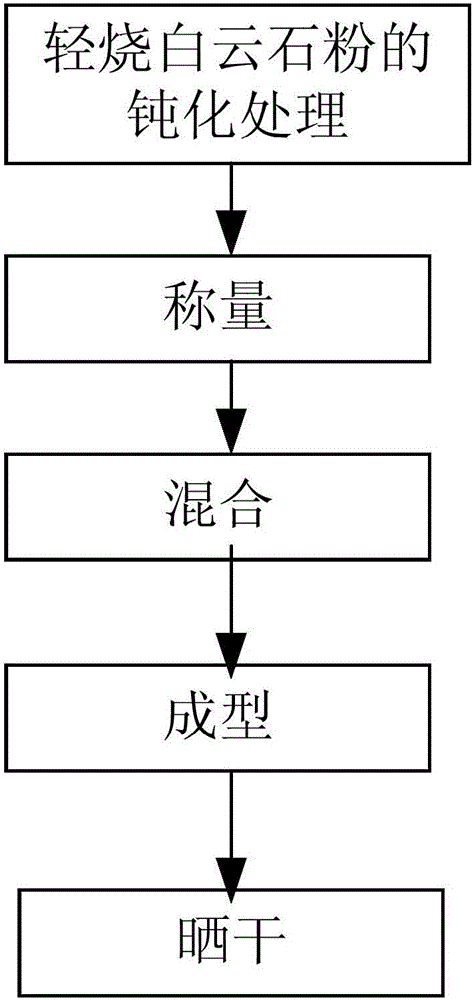

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are given below to describe the technical solution of the present invention in detail.

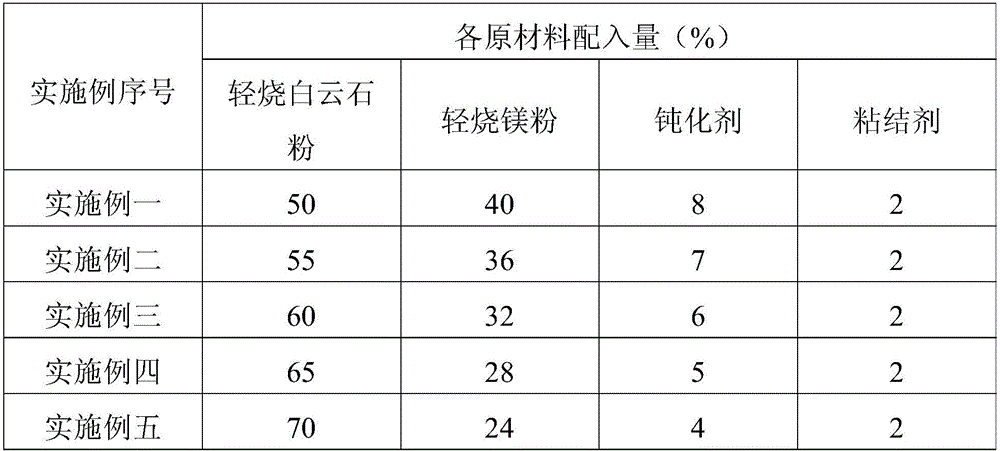

[0028] The weight ratio of each raw material of the light-burned briquetting ball for converter steelmaking in the present invention is: light-burned dolomite powder 50-80%, light-burned magnesium powder 20-40%, passivator 5-20%, binder 0.5- 10.

[0029] MgO≥30% and CaO≥50% in lightly burned dolomite powder; SiO2≤2% and MgO≥70% in lightly burned magnesium powder. For example: MgO in lightly burned dolomite powder: 30%~35%, CaO: 50%~55%; SiO2 in lightly burned magnesium powder: 0~2%, MgO: 70%~90%.

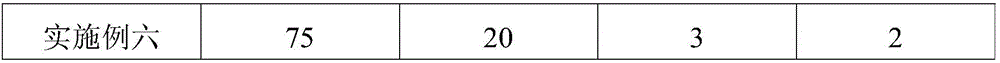

[0030] The formula of embodiment is as table 1:

[0031] Table 1

[0032]

[0033]

[0034] The particle size of the lightly burned dolomite powder is 0-5 mm, and the particle size of the raw dolomite is 0-5 mm.

[0035] The particle size of light-fired briquettes for converter steelmaking is 10-50 mm.

[0036] The binder is on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com