Hanging-basket-type straw marsh gas fermentation system

A biogas fermentation and fermentation system technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, gas production bioreactor, etc., can solve the problem of low gas production efficiency and energy consumption of anaerobic digestion High problems, to achieve the effect of convenient feeding and discharging, simple operation and maintenance, and preventing the straw from floating and crusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

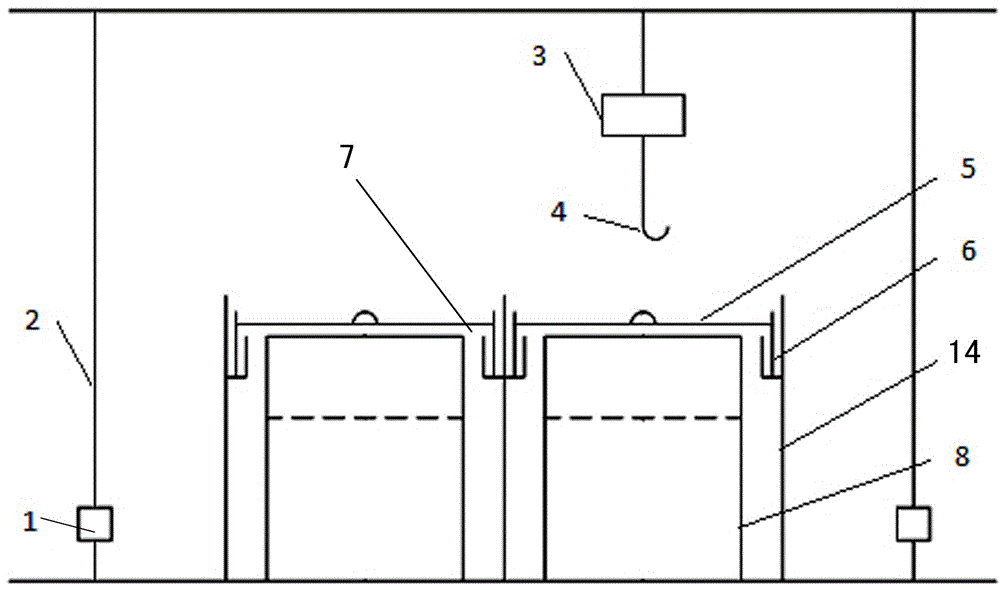

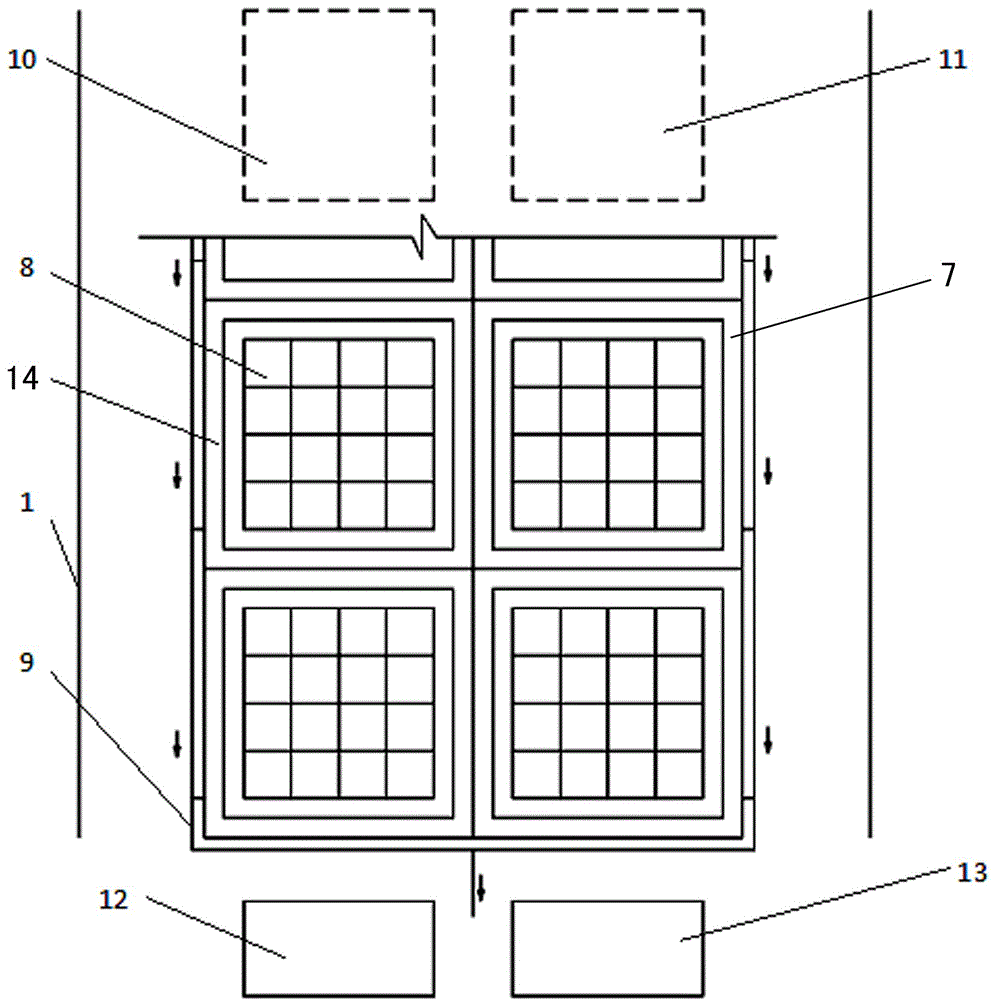

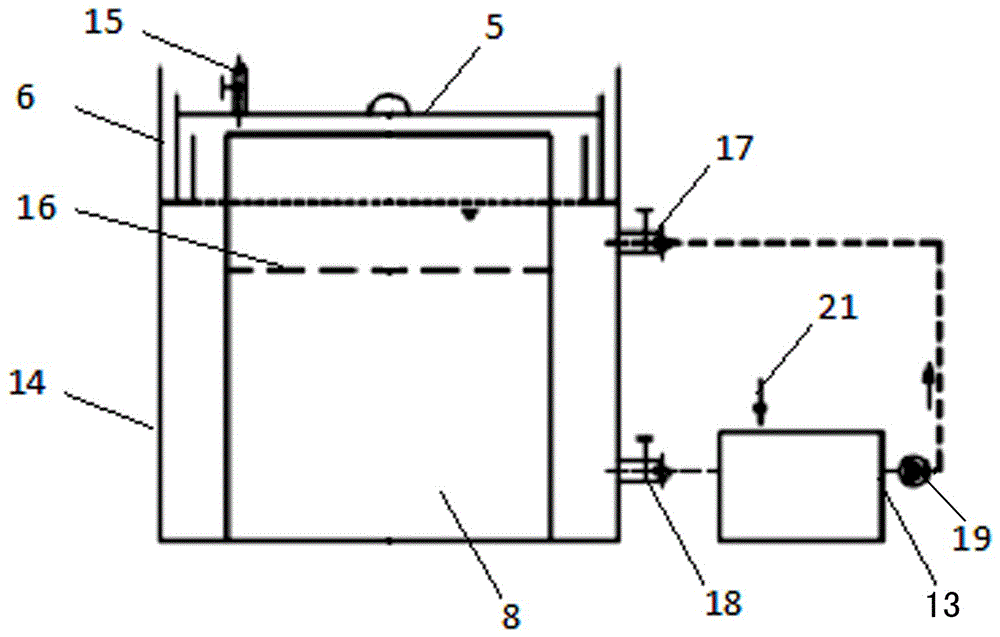

[0019] The hanging basket straw biogas fermentation system in this example, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the hanging basket type straw biogas fermentation system is composed of a lifting system and a fermentation system 7. The lifting system is composed of a track 1, a lifting frame 2, a lifting device 3 and a hook 4. The track 1 is laid on both sides of the fermentation system 7. Lifting The frame 2 is installed on the track 1, the beam of the lifting frame 2 is equipped with a lifting device 3, and the lower end of the lifting device 3 is a hook 4; the fermentation system 7 is composed of 30 single fermentation devices 14, straw charging area 10, biogas residue The unloading area 11 and the biogas slurry circulation stirring system 13 are composed; the monomeric fermentation device 14 is a single sequential batch fermentation tank, and the upper part is provided with a water-sealed weir 6, the inner wall of the water-sealed w...

Embodiment 2

[0031] In the hanging basket type straw biogas fermentation system of this example, the sealing cover 5 is provided with a counterweight.

[0032] All the other are the same as embodiment one.

Embodiment 3

[0034] In the hanging basket type straw biogas fermentation system of this example, there is no communication port at the lower part of the sealing cover 5 .

[0035] All the other are with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com