Modified asphalt sizing material and preparation method thereof, as well as asphalt waterproof coiled material

A technology of asphalt waterproofing membrane and modified asphalt, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of aging of membranes, damage to the health of construction personnel, and inconvenience of construction, so as to improve the softening point and improve the softening point , The effect of facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

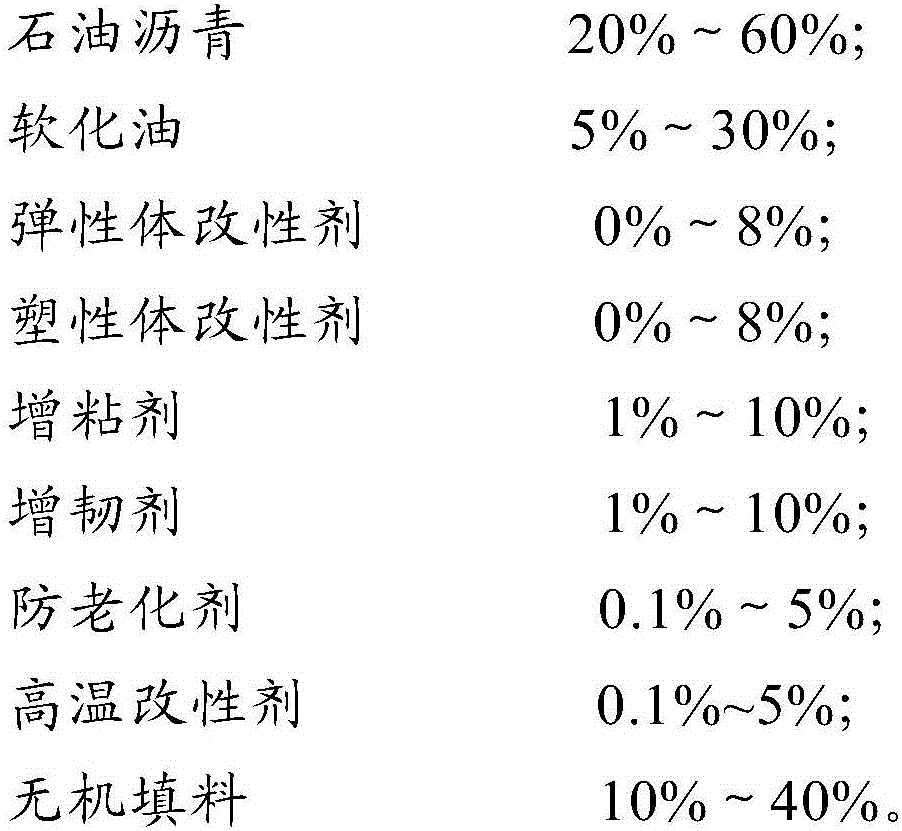

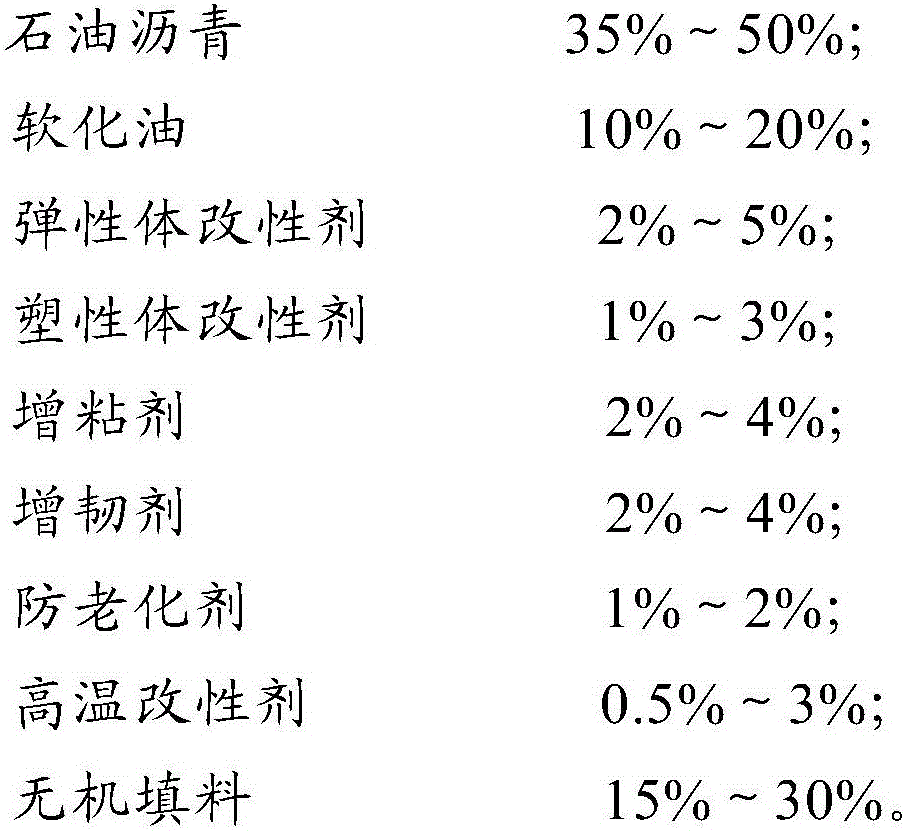

[0044] This embodiment provides a modified asphalt compound, the raw material formula of which includes: petroleum asphalt, softening oil, elastomer modifier and / or plastomer modifier, tackifier, toughener, antiaging agent, high temperature Modifiers, inorganic fillers, and high-temperature modifiers are stearylamides with more than six carbon alkyl groups.

[0045] The high-temperature modifier in the raw material formula of the modified asphalt compound in this embodiment is a stearylamide with more than six carbon alkyl groups, and the high-temperature modifier contains an amide group, wherein the N in the amide group The hydrogen element on the surface is relatively active, and it is easy to form hydrogen bonds with the benzene rings, -O-, -S-, etc. in the petroleum asphalt, so that the modified asphalt rubber system is relatively stable. And the amide group in the high-temperature modifier forms a relatively stable large group through hydrogen bonds, thereby increasing th...

Embodiment 2

[0047] This embodiment provides a modified asphalt compound, the raw material formula of which includes the following components in mass percentage:

[0048]

[0049] The high-temperature modifier is stearylamides whose high-temperature modifier is more than six carbon alkyl groups.

[0050] The petroleum asphalt is No. 90 petroleum asphalt.

[0051] The softening oil is line reduction oil and furfural extraction oil (mass ratio is 3:1).

[0052] The plastomer modifier was diisopropyl peroxydicarbonate (IPP). The melting point of the plastomer modifier is 90°C to 130°C.

[0053] The tackifier is a styrene resin.

[0054] The toughening agent is acrylate rubber.

[0055] Antiaging agent is sulfur.

[0056] The inorganic filler is heavy calcium.

[0057] This embodiment provides a method for preparing the above-mentioned modified asphalt compound, which includes the following steps: mixing, developing and swelling the substances in the raw material formula to obtain the...

Embodiment 3

[0059] This embodiment provides a modified asphalt compound, the raw material formula of which includes the following components in mass percentage:

[0060]

[0061] The molecular weight of the high temperature modifier is 280-2000.

[0062] The high-temperature modifiers are N,N'-methylene bis-octadecamide and ethylene bis-stearic acid amide (mass ratio: 1:1).

[0063] The petroleum asphalt is No. 70 petroleum asphalt.

[0064] The softening oil is naphthenic oil.

[0065] The elastomer modifiers are styrene-butadiene-styrene block copolymer (SBS) and styrene-butadiene rubber (SBR) (mass ratio 1:5). The glass transition temperature of the elastomer modifier is -60°C to -40°C.

[0066] The plastomer modifier is polypropylene (PP). The melting point of the plastomer modifier is 90°C to 130°C.

[0067] Tackifiers are C5 petroleum resin and C9 petroleum resin (mass ratio is 2:5).

[0068] The toughening agent is chlorosulfonated polyethylene and acrylonitrile-butadiene-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com