Method for harmlessly treating BDO organic waste liquid

A technology of harmless treatment and organic waste liquid, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high production cost, low production efficiency, complicated procedures, etc. Efficiency improvement, simple effect of desalination method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

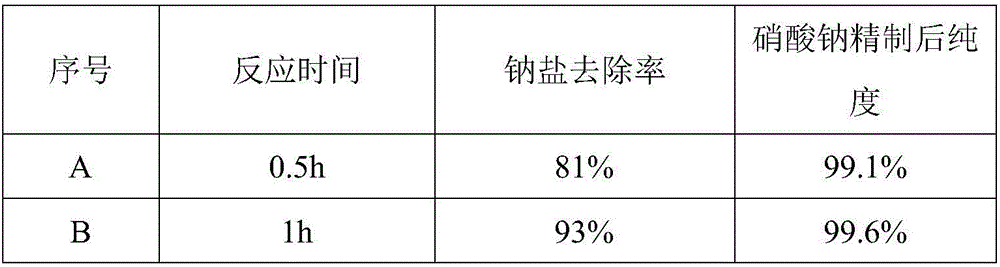

[0038] In this embodiment, the BDO waste alcohol solution with a concentration of 20-30% and nitric acid with a concentration of 40% are used to adjust the pH value to 3-4. The reaction conditions are: liquid temperature 100°C-130°C, reaction pressure normal pressure, and the reaction result See Table 1:

[0039] Table 1

[0040]

[0041]

Embodiment 2

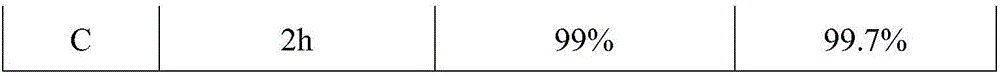

[0043] In this embodiment, the concentration of 30-40% BDO waste alcohol and 60% concentration of nitric acid are used to adjust the pH value to 4-5. The reaction conditions are: liquid temperature 130°C-150°C, reaction pressure normal pressure, and the reaction results are shown in Table 2.

[0044] Table 2

[0045]

Embodiment 3

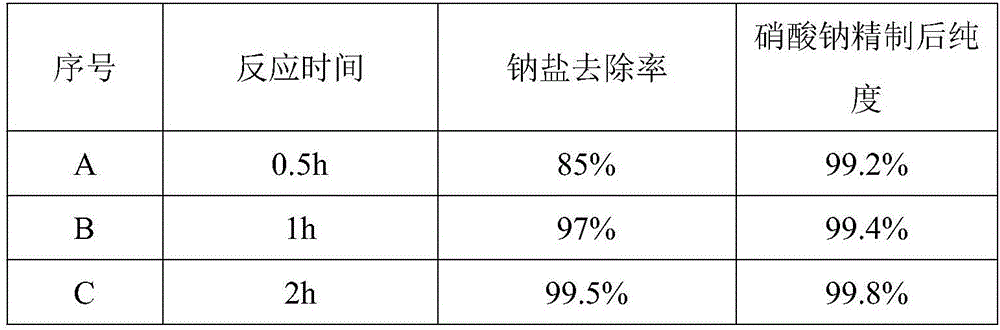

[0047] In this embodiment, the concentration of 40-50% BDO waste alcohol and 50% concentration of nitric acid are used to adjust the pH value to 5-6. The reaction conditions are: liquid temperature 140°C-160°C, reaction pressure normal pressure, and the reaction results are shown in table 3.

[0048] table 3

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com