Method for purifying butadiene hexafluoride

A technology of hexafluorobutadiene and graphene, applied in the field of purification, can solve the problems of HFBD purity and yield decline, and achieve the effect of high adsorption and increase of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

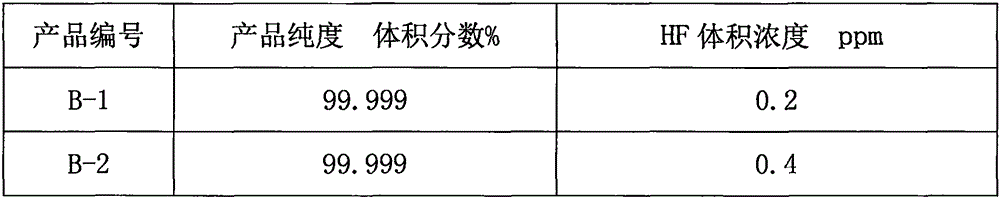

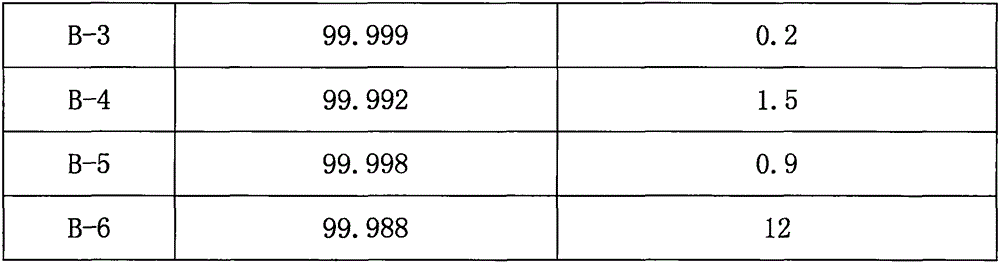

Examples

Embodiment 1

[0019] (1) Preparation of efficient adsorbent

[0020] Add 100Kg of adsorption resin to a 2000L reactor with a specific surface area of 800m 2 / g, 8Kg graphene oxide aqueous solution (mass percentage concentration 15), 0.3Kg potassium borohydride, 800Kg pure water mixed, stirred at 80°C for 50h, filtered, dried, passed into nitrogen, roasted at 300°C for 2h, 700°C It was calcined at ℃ for 3h, at 1100℃ for 2h, and cooled to room temperature to obtain a high-efficiency adsorbent.

[0021] (2) Purification of hexafluorobutadiene

[0022] Crude hexafluorobutadiene undergoes the well-known impurity removal and refining technology in the industry, including extraction technology to separate the solvent, absorbs moisture through molecular sieves, and then enters the adsorption tower equipped with this high-efficiency adsorbent. At 20 ° C, the pressure is 0.5 MPa, and the flow rate is 3 BV Adsorbed under the condition of / h, the adsorbed hexafluorobutadiene is then subjected to th...

Embodiment 2

[0024] (1) Preparation of efficient adsorbent

[0025] Add 100Kg of adsorption resin to a 2000L reactor with a specific surface area of 500m 2 / g, 2Kg graphene oxide aqueous solution (mass percentage concentration 5), 0.05Kg potassium borohydride, 300Kg pure water mixed, stirred at 50°C for 30h, filtered, dried, passed into nitrogen, roasted at 200°C for 1h, 500°C It was calcined at ℃ for 1 h, and at 900 °C for 1 h, and cooled to room temperature to obtain a highly efficient adsorbent.

[0026] (2) Purification of hexafluorobutadiene

[0027] Crude hexafluorobutadiene undergoes the well-known impurity removal and refining technology in the industry, including extraction technology to separate the solvent, absorbs moisture through molecular sieves, and then enters the adsorption tower equipped with this high-efficiency adsorbent. At 0 ° C, the pressure is 0.1 MPa, and the flow rate is 1 BV Adsorbed under the condition of / h, the adsorbed hexafluorobutadiene is then subjecte...

Embodiment 3

[0029] (1) Preparation of efficient adsorbent

[0030] Add 100Kg of adsorption resin to a 2000L reactor with a specific surface area of 1000m 2 / g, 10Kg graphene oxide aqueous solution (mass percentage concentration 5), 0.5Kg potassium borohydride, 1000Kg deionized water were mixed, stirred at 100°C for 80h, filtered, dried, passed into nitrogen, and roasted at 400°C for 3h, Calcined at 800°C for 5 hours, 1200°C for 5 hours, and cooled to room temperature to obtain a high-efficiency adsorbent.

[0031] (2) Purification of hexafluorobutadiene

[0032] Crude hexafluorobutadiene undergoes well-known impurity removal and refining technologies in the industry, including extraction technology to separate solvents, and then absorbs moisture through molecular sieves, and then enters the adsorption tower equipped with this high-efficiency adsorbent. At 30°C, pressure 1MPa, flow rate 5BV / Adsorbed under the condition of h, the adsorbed hexafluorobutadiene undergoes impurity removal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com