concrete retarder

A retarder, concrete technology, applied in the field of concrete retarder, can solve the problems of unsatisfactory concrete strength, air pollution, etc., to achieve the effect of improving the retarding effect, improving the adsorption performance, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

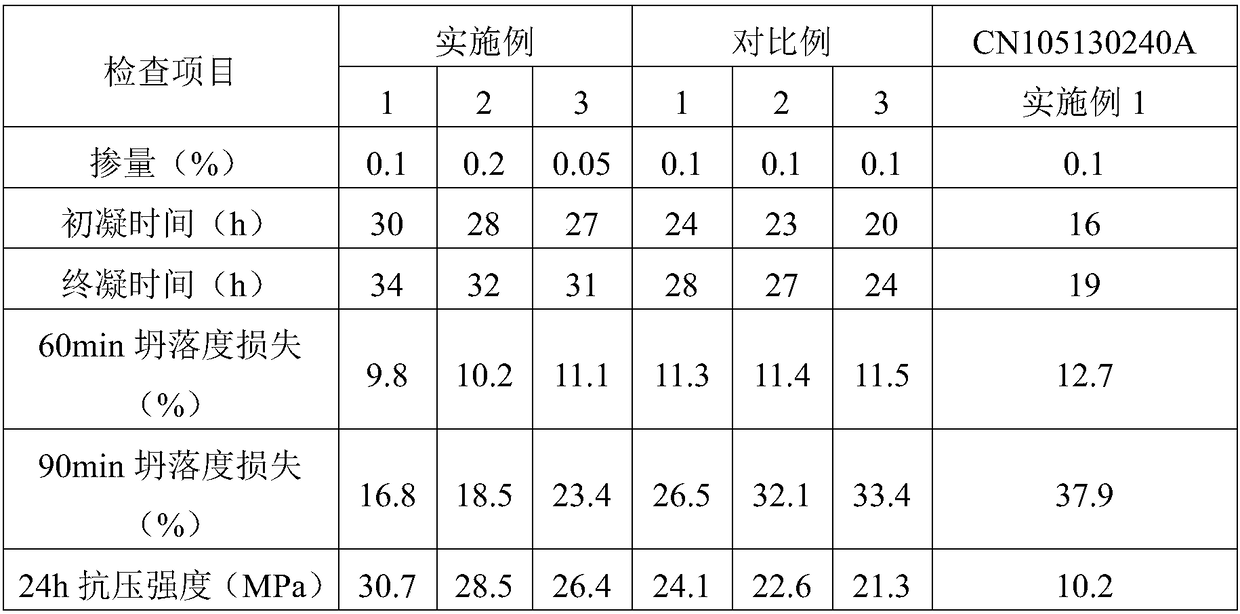

Examples

Embodiment 1

[0038] A concrete retarder, made of the following components in proportion by weight: 3 parts of ammonium borate, 5 parts of sodium pyrophosphate, 6 parts of magnesium sulfate, 8 parts of diethylenetriaminepentamethylenephosphonic acid, carboxymethyl 5 parts of sodium cellulose, 3 parts of maltodextrin, 2 parts of sodium tartrate, 18 parts of palygorskite powder, 5 parts of water reducer, 2 parts of dispersant, and 0.7 part of surfactant.

Embodiment 2

[0040]A concrete retarder, made of the following components in proportion by weight: 5 parts of ammonium borate, 8 parts of sodium pyrophosphate, 9 parts of magnesium sulfate, 9 parts of diethylenetriaminepentamethylenephosphonic acid, carboxymethyl 6 parts of sodium cellulose, 4 parts of maltodextrin, 3 parts of sodium tartrate, 20 parts of palygorskite powder, 7 parts of water reducer, 3 parts of dispersant, and 0.8 part of surfactant.

Embodiment 3

[0042] A concrete retarder, made of the following components in proportion by weight: 2 parts of ammonium borate, 3 parts of sodium pyrophosphate, 4 parts of magnesium sulfate, 6 parts of diethylenetriaminepentamethylenephosphonic acid, carboxymethyl 3 parts of sodium cellulose, 1 part of maltodextrin, 1 part of sodium tartrate, 15 parts of palygorskite powder, 4 parts of water reducer, 1 part of dispersant, and 0.5 part of surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com