Automatic system for preparing lithium hydroxide

An automated system, lithium hydroxide technology, applied in the direction of lithium oxide;/hydroxide, etc., can solve the problems of using more devices, increasing the cost of lithium hydroxide preparation, long time, etc., and achieve the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The lithium hydroxide preparation automation system involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0037]

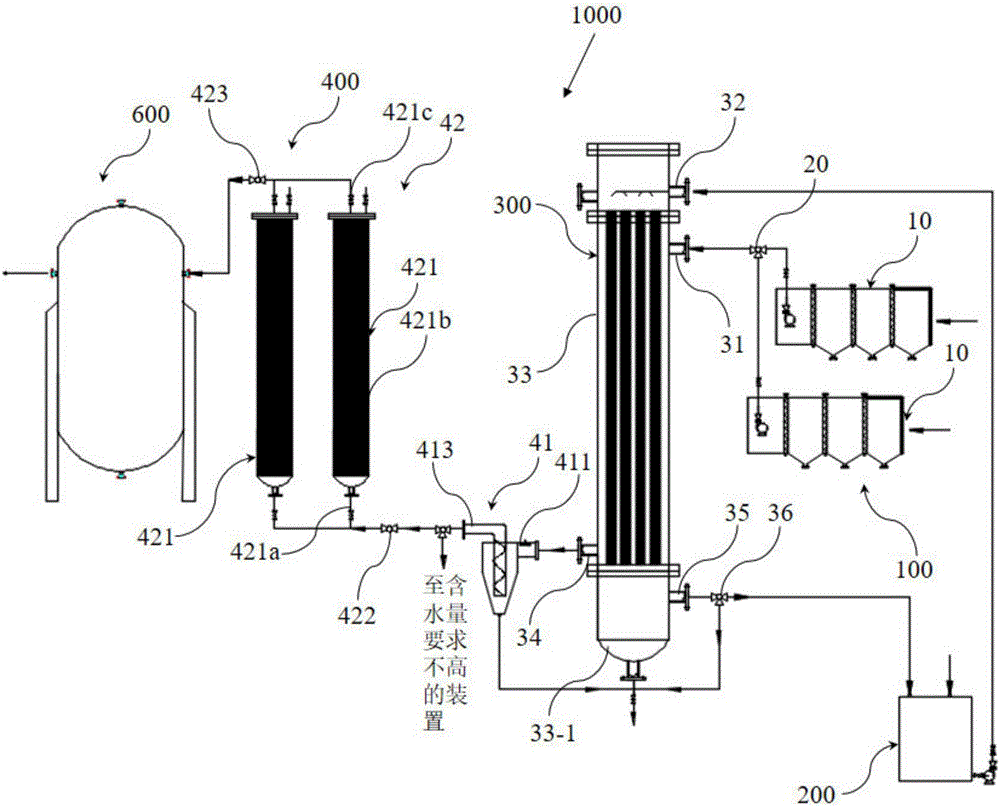

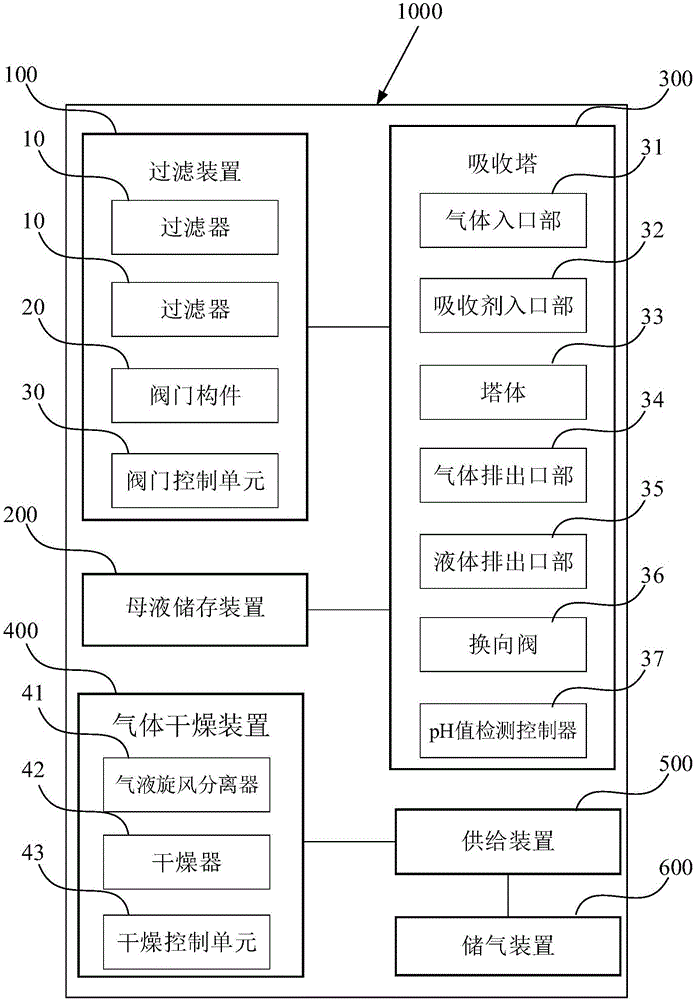

[0038] In this embodiment, the lithium hydroxide preparation automation system is used to prepare battery-grade lithium hydroxide products, which includes a preparation subsystem and a protective gas supply subsystem.

[0039] The preparation subsystem uses lithium salts such as crude lithium carbonate, industrial grade lithium carbonate, lithium chloride, and lithium sulfate as raw materials to prepare lithium hydroxide products, which includes: raw material removal device, causticization device, concentration crystallization device, crystal drying device , crushing device and screening and packaging device.

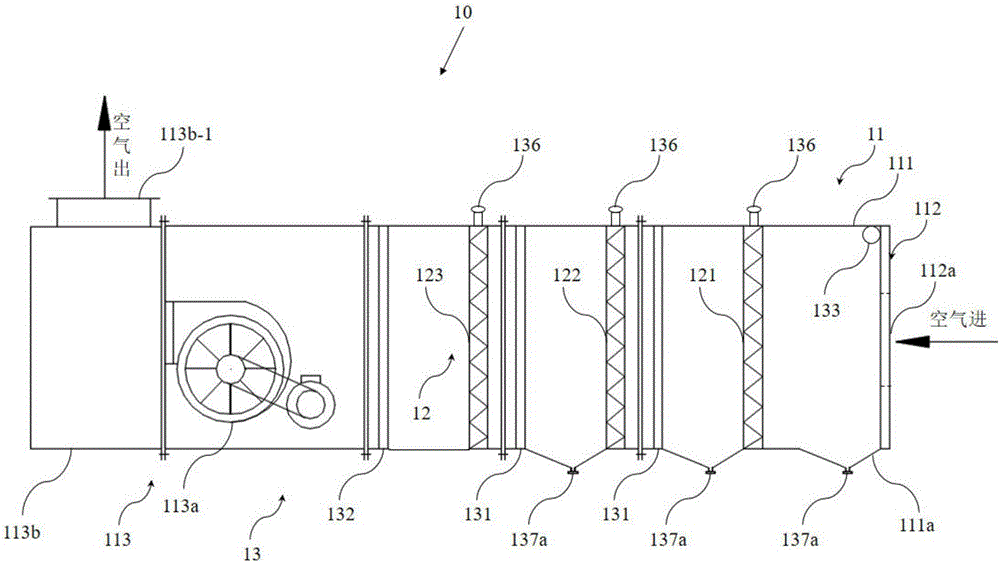

[0040] The protective gas supply subsystem is used to remove carbon dioxide in the air, so as to provide carbon dioxide-free air as a protective gas for the preparation process of lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com