Multifunctional coffee dual-line filling machine

A multi-functional, filling machine technology, used in packaging, transportation packaging, packaging protection, etc., can solve the problems of low production efficiency, high heat sealing defect rate, inaccurate positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

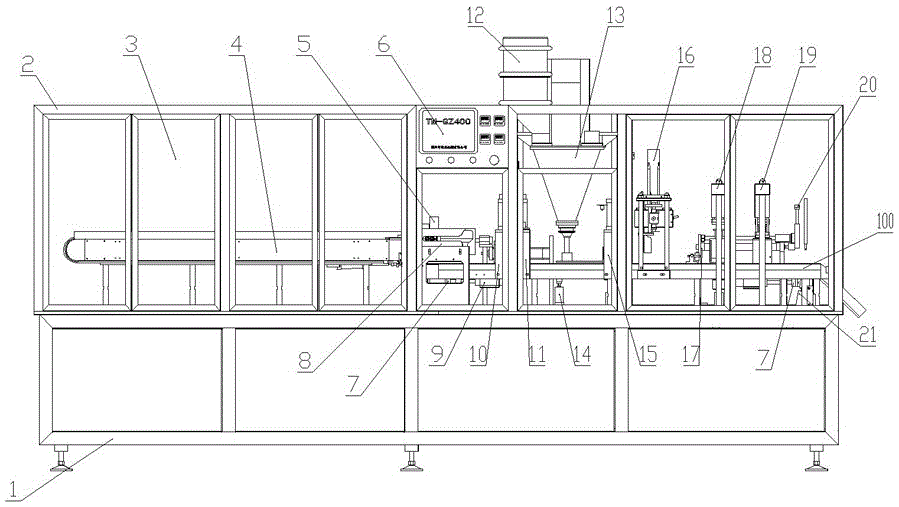

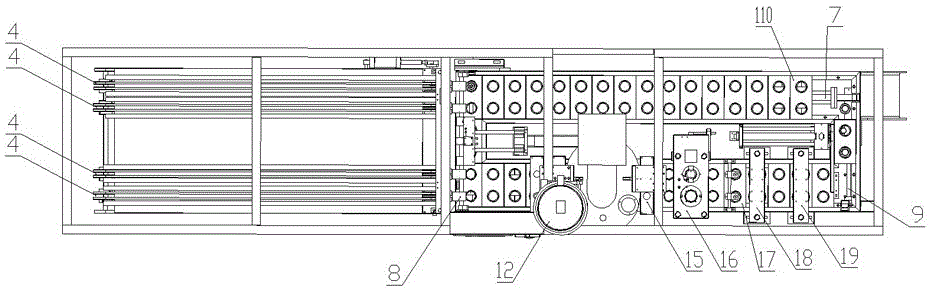

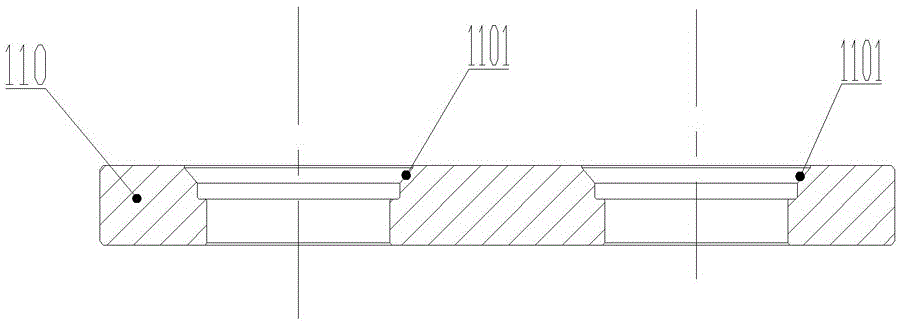

[0029] Such as figure 1 with figure 2 Shown: a multifunctional coffee double-row filling machine, including a frame 1, an upper frame door frame 2, a door 3, a cup feeding device 4, a touch screen 6, and a cup feeding device 4 installed on the frame 1 The cup blocking device 5, the template rail 100, the template rail 100 are provided with a longitudinal cylinder 7 and a transverse cylinder 9 at both ends, a number of templates 110 are slidably mounted on the template rail 100, and the corresponding positions of the template 110 are arranged in pairs according to the cup mounting process There are cup grasping device 8, inner cup pressing device 10, inner cup detecting device 11, discharging device 13, powder suction and discharge device 15, suction film device 16, film detection device 17, heat sealing nitrogen filling device 18, capsule cup heat The sealing device 19, the cup suction device 20, a vacuum feeding device 12 is provided above the blanking device 13, a powder shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com