Printing machine with integrated printing and adsorption function

A printing machine and functional technology, applied in printing, printing devices, etc., can solve the problems of inconvenient replacement, weak versatility, and high cost, and achieve the effect of ensuring printing quality, large market competitiveness, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

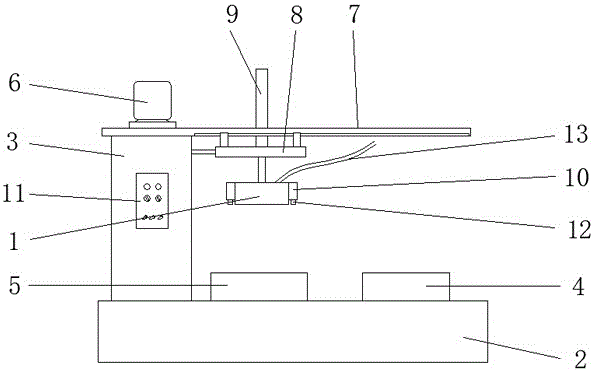

[0018] Such as figure 1 A printing machine with integrated printing and adsorption functions is shown, including: a printing head 1, a base 2, and a support column 3 with an electric control system inside; the support column 3 is arranged on the upper side of the base 2; A printing chamber 4 and a drying chamber 5 arranged side by side are arranged on the base 2; the printing head 1 is an inkjet printing head; in addition, a drive mechanism 6 is arranged above the support column 3, and a sliding sliding door extending outward is arranged on the side. Frame 7; Slide frame 7 is provided with guide rail, is provided with the fixed plate 8 that can slide along its guide rail below the slide frame 7; In order to realize moving up and down, the middle part of described fixed plate 8 is provided with the elevating cylinder 9 that vertically installs with it ; The print head 1 is fixed on the piston rod end of the lift cylinder 9; in order to realize automatic adsorption, the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com