Monolateral cavity freestyle foaming mould

A foaming mold, unilateral technology, applied in the field of unilateral cavity free foaming mold, can solve the problems of substandard mechanical properties of products, affecting the cushioning performance of products, insufficient foaming of products, etc., and solve the problem of high market price , good practical effect, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

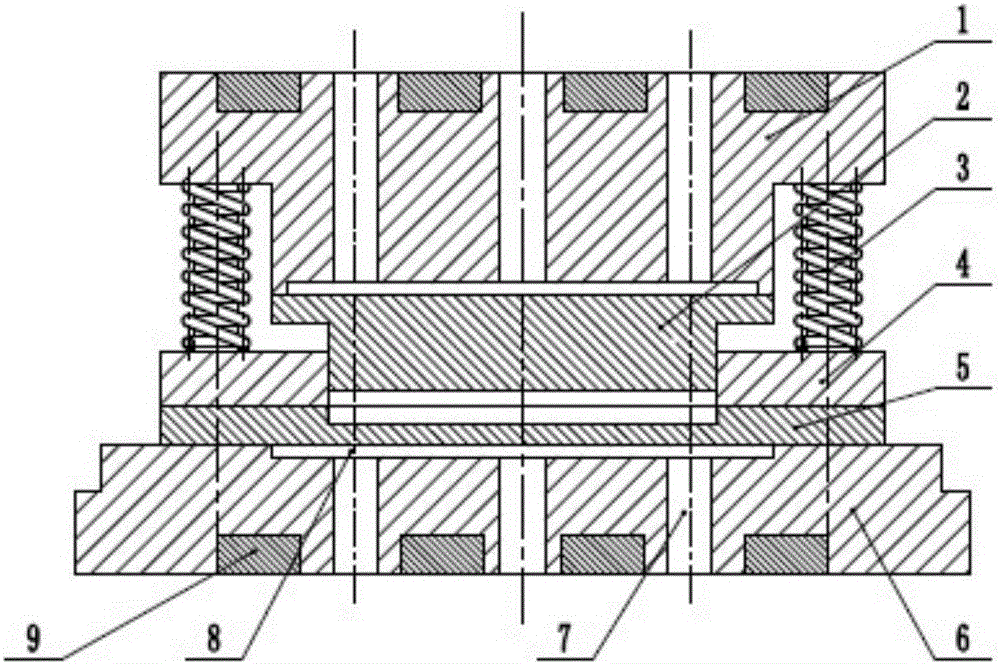

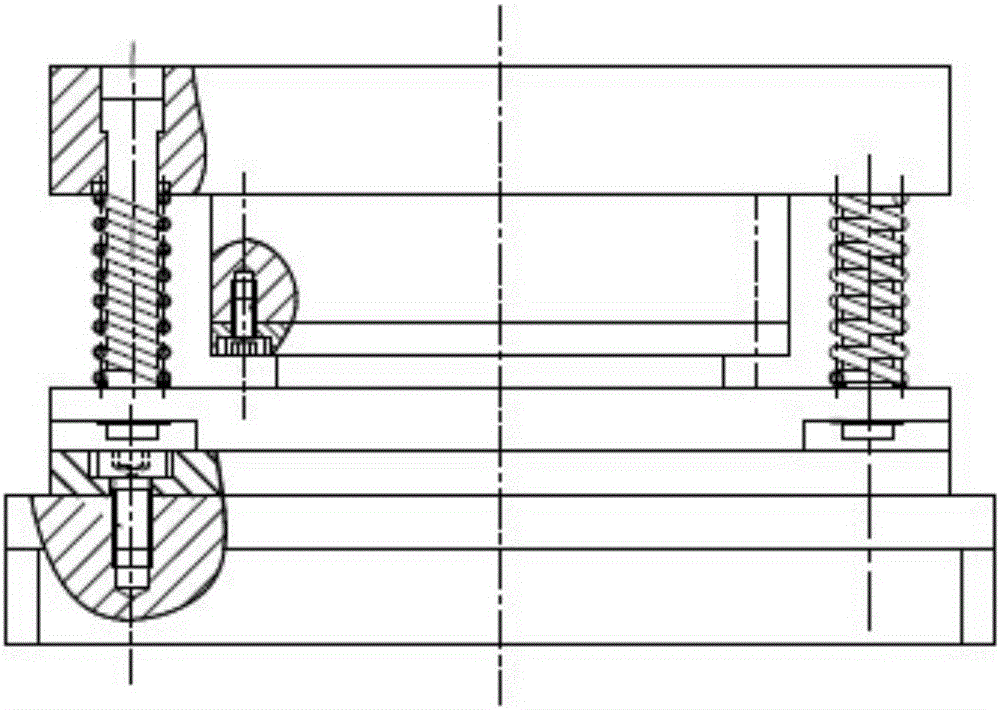

[0036] like Figure 1-2 As shown, the unilateral cavity free-form foaming mold includes aluminum alloy upper base 1, breathable steel upper mold 2, spring 3, aluminum alloy baffle 4, breathable steel lower mold 5, aluminum alloy lower base 6, row The air hole 7, the base sinking groove 8, the electric heating plate 9 and the unilateral foaming cavity 10, the breathable steel upper mold 2 and the breathable steel lower mold 5 are combined to form the cavity of the mold, the aluminum alloy upper base 1 and the aluminum alloy A spring 3 is arranged between the alloy baffles 4, such as image 3 As shown, the spring 3 is fixed on the lower surface of the upper base 1 of the aluminum alloy. After the upper and lower molds of the breathable steel are completed to mold the biomass material products, the upper and lower molds of the breathable steel rise a certain distance under the action of the resilience of the spring 3, so that the product is A unilateral foaming cavity 10 is form...

Embodiment 2

[0046] The single-sided cavity free-form foaming mold includes an upper mold and a lower mold. The surface of the lower mold is provided with a groove for placing biomass materials. Part of the upper mold can be embedded in the groove. The other side moves relatively to extrude the biomass material, so that the biomass material is formed in the groove, the upper die and the lower die are respectively connected with the moving mechanism, and the moving mechanism acts after the upper die and the lower die extrude the biomass material for a set time. The lower and upper molds are separated from the lower mold; in this solution, the upper mold or the lower mold can move relative to each other, which improves the separation rate of the two, and the moving mechanism can be an electric cylinder or other power devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com