Vibration grinding method with active impact and rotational grinding of grinding medium

A grinding method and a grinding medium technology, which are applied in the preparation, sampling, and measuring devices of test samples, can solve problems such as high energy consumption, low grinding efficiency, and spring fatigue failure, and achieve improved stress conditions and service life , Reduce the effect of the vibration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

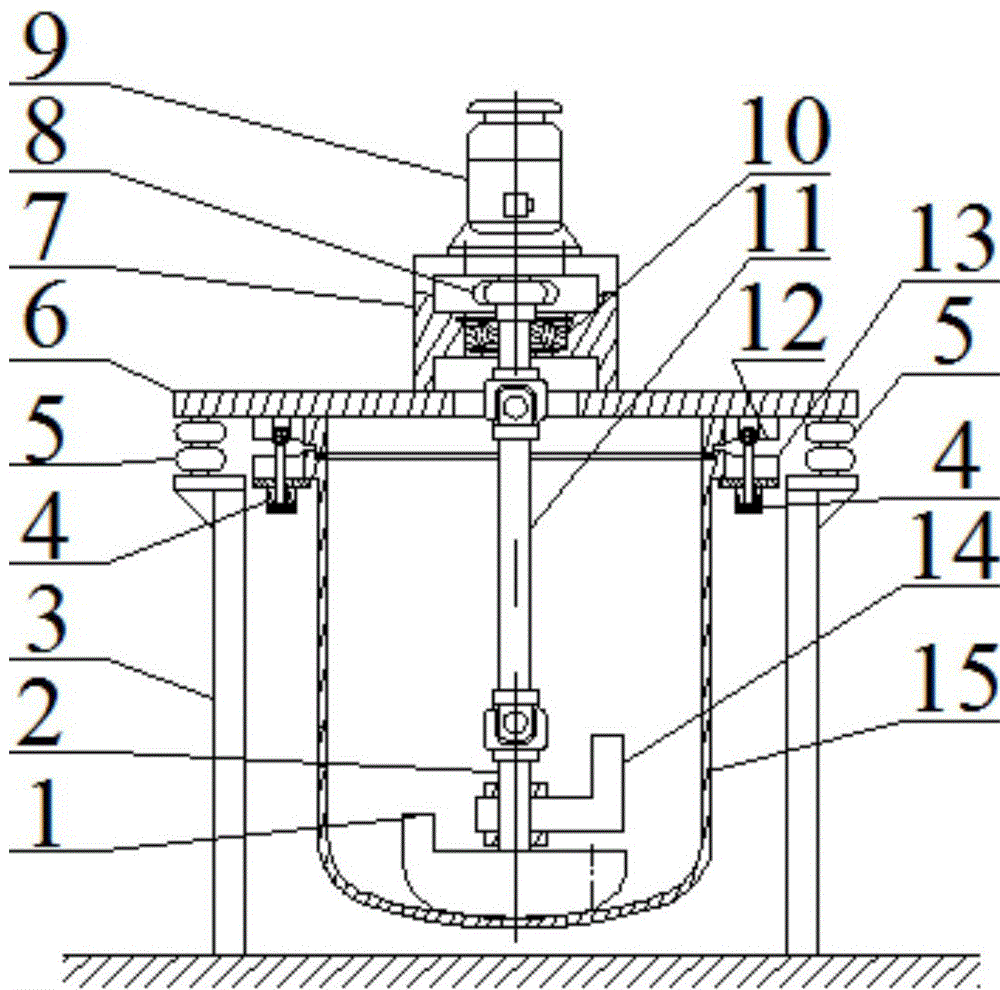

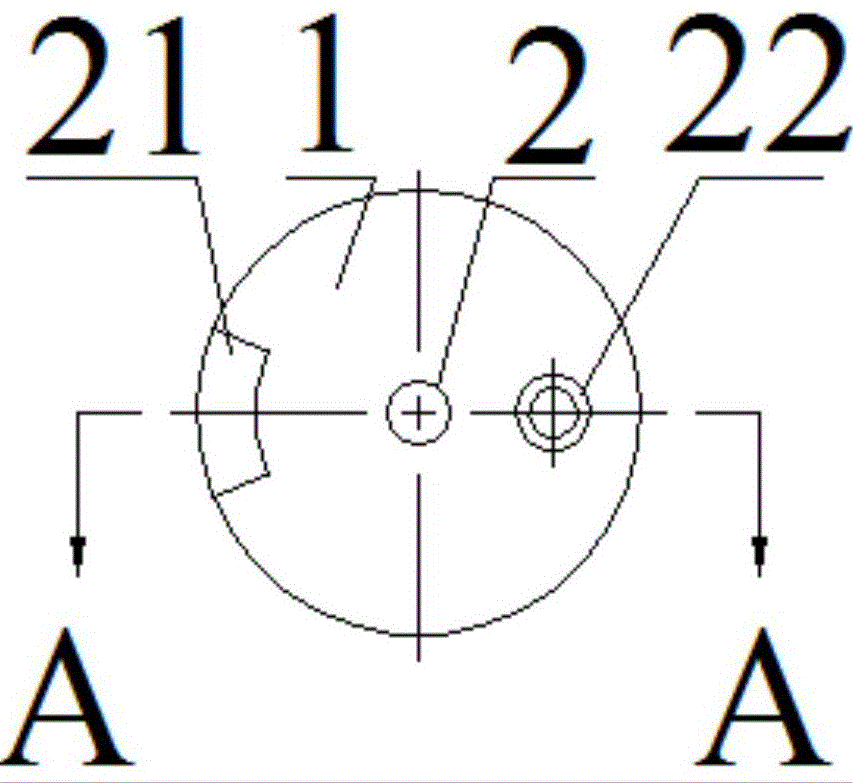

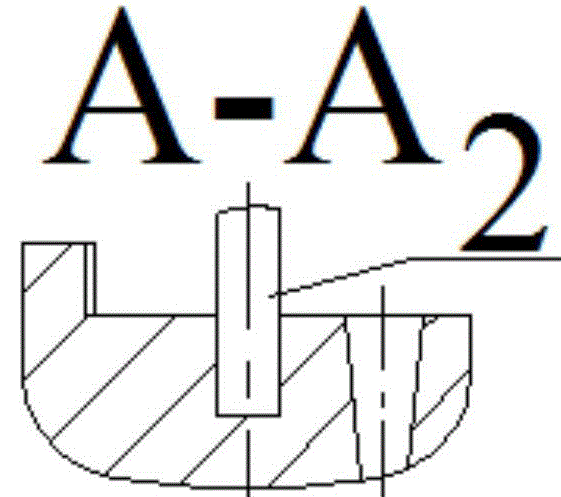

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, below in conjunction with the applicant's vertical vibration mill (patent CN201620321364.4) describes the embodiment of the present invention in detail, and compares its effect with a vertical vibration mill that is ground by a traditional method, and analyzes the effect of the method Pros and cons.

[0038] Before the work starts, open the locking device 4, realize the rapid separation of the grinding chamber 15 and the movable support 6 through the upper concave-convex flange 12 and the lower concave-convex flange 13, so that the materials are loaded into the grinding chamber 15, and then close after the loading is completed. The upper concave-convex flange 12 and the lower concave-convex flange 13, and close the locking device 4.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com