Probe sealing structure and testing system

A sealing structure and testing system technology, applied in the medical field, can solve the problems of unsatisfactory production volume, probe wire damage, low production efficiency, etc., and achieve high work efficiency, fast assembly and disassembly speed, and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

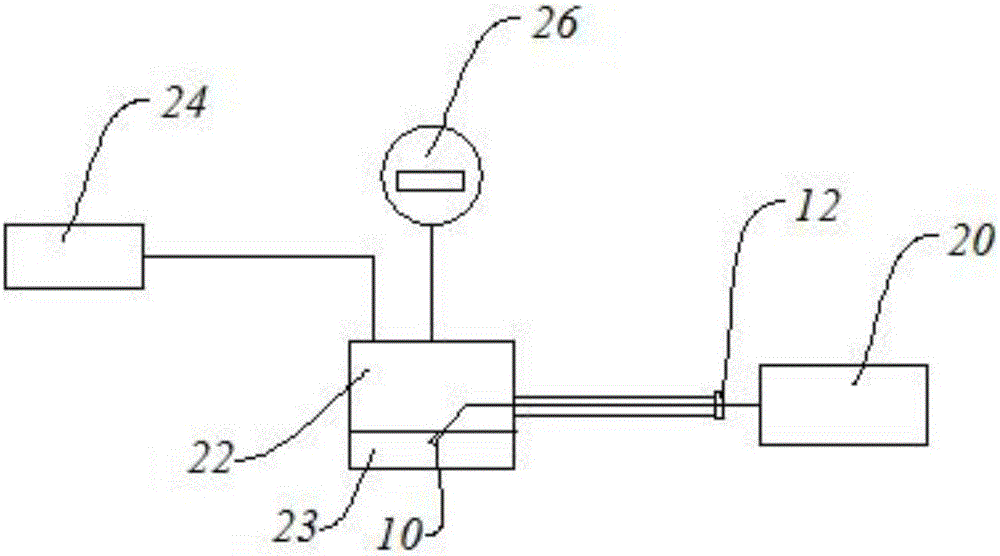

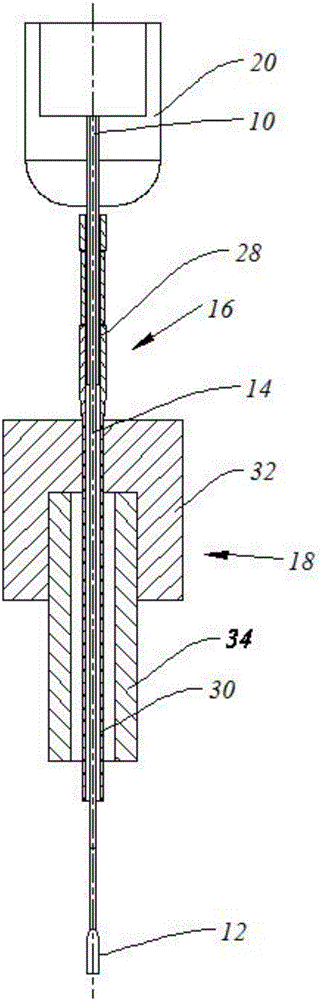

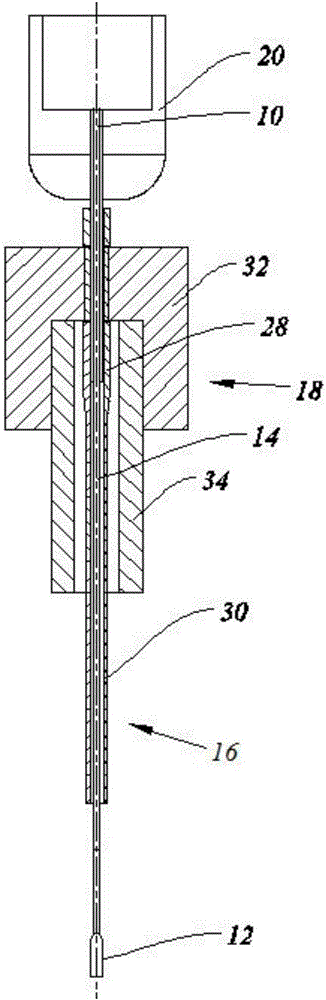

[0022] Such as Figure 1 to Figure 4 As shown, a preferred embodiment of the present invention provides a test system for testing a probe, wherein the probe is used to detect the pressure in the skull of a patient, to determine whether the probe is qualified. The test system includes a sealed structure of the probe, wherein the probe includes a sensor 10, a probe connector 12, a wire 14 connecting the sensor 10 and the probe connector 12, and the sealed structure includes a protective tube 16 surrounding the periphery of the wire 14 and a seal surrounding the periphery of the protective tube 16. Conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com