Screw-in electric bottom fire explosion-proof tightening machine

A technology of tightening machine and explosion-proof motor, which is applied in power tools, weapon accessories, fuzes, etc., can solve the problems of artificial quality and safety, and achieve the effect of ensuring product quality, ensuring precision control, and ensuring safety.

Inactive Publication Date: 2008-07-30

SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the artificial quality and safety problems when manually screwing in the electric primer, the invention provides a screw-in electric primer explosion-proof screwing machine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

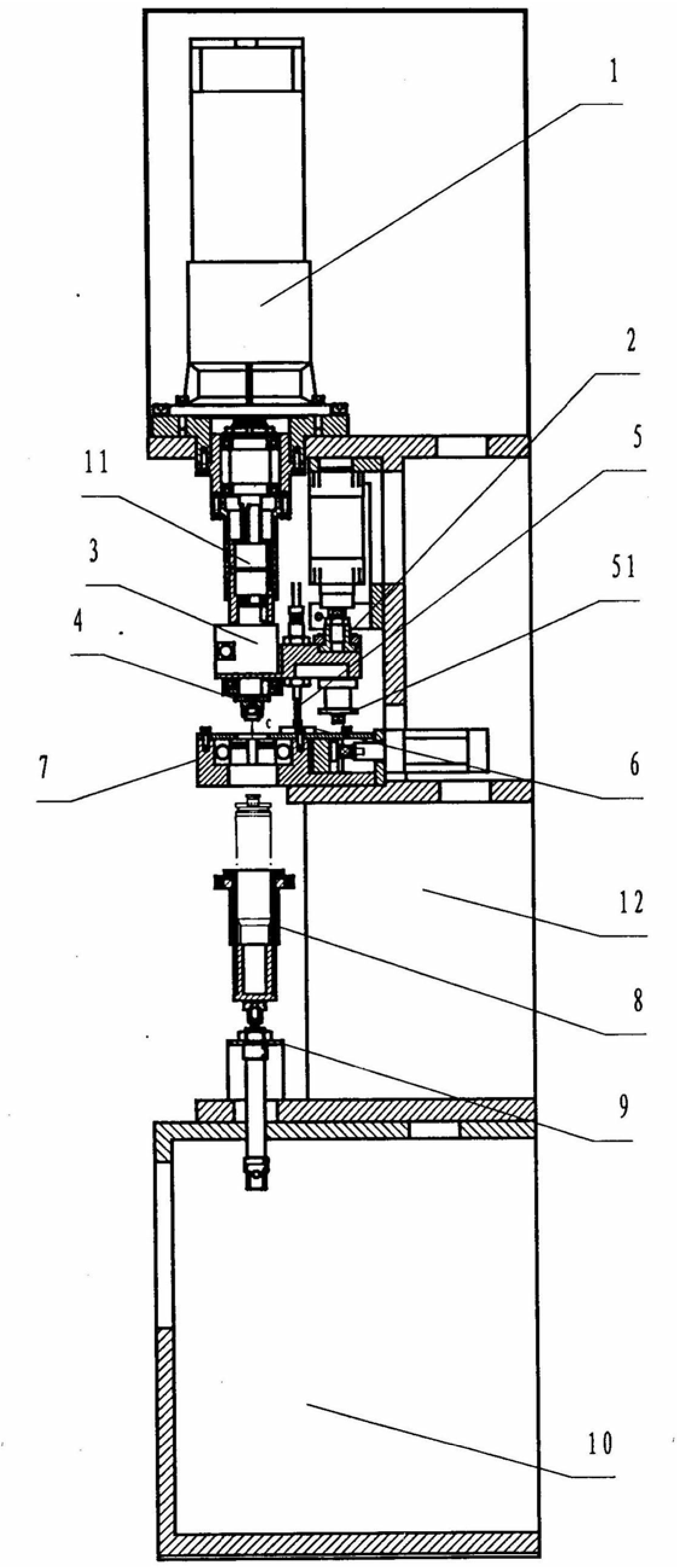

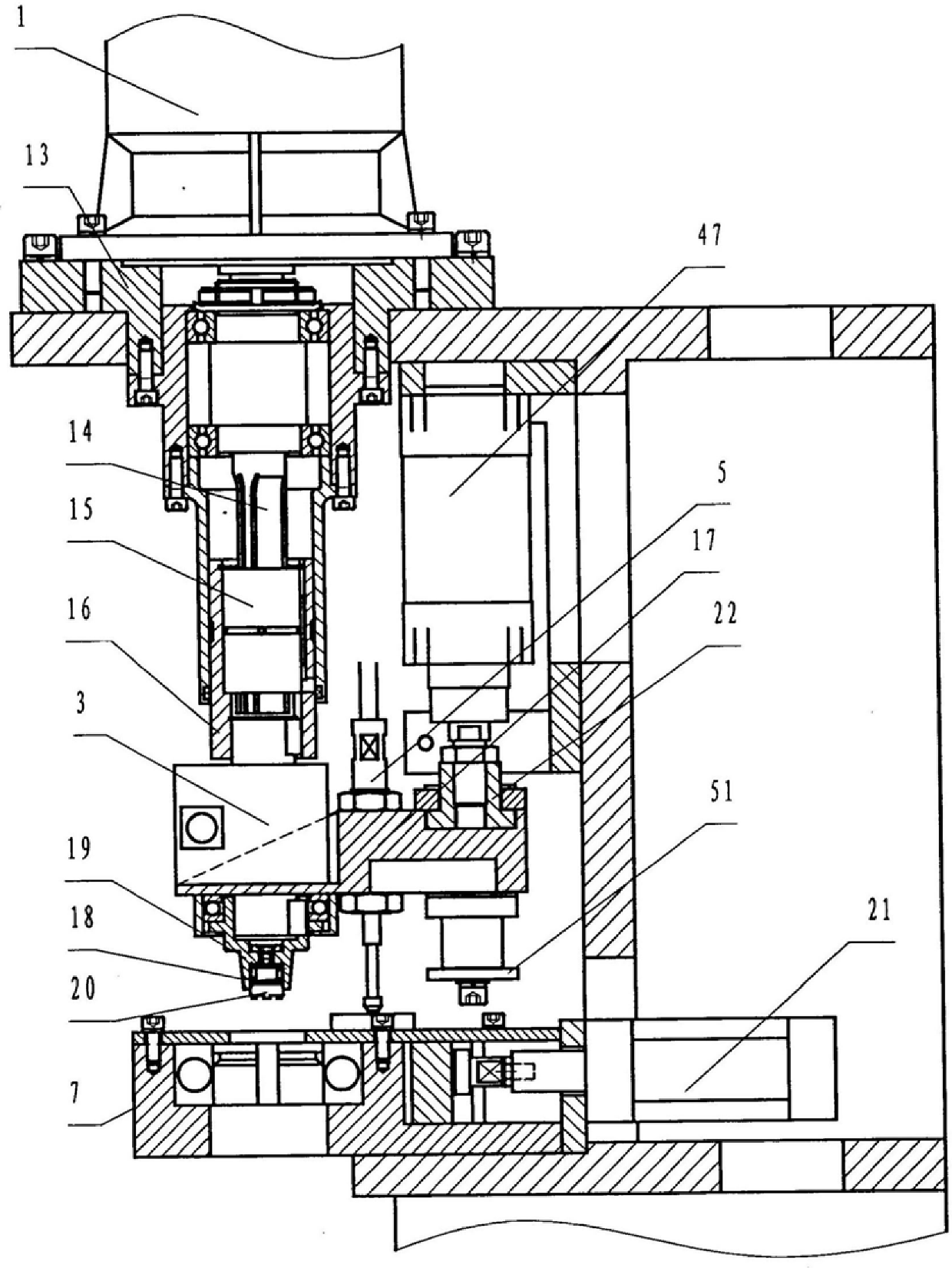

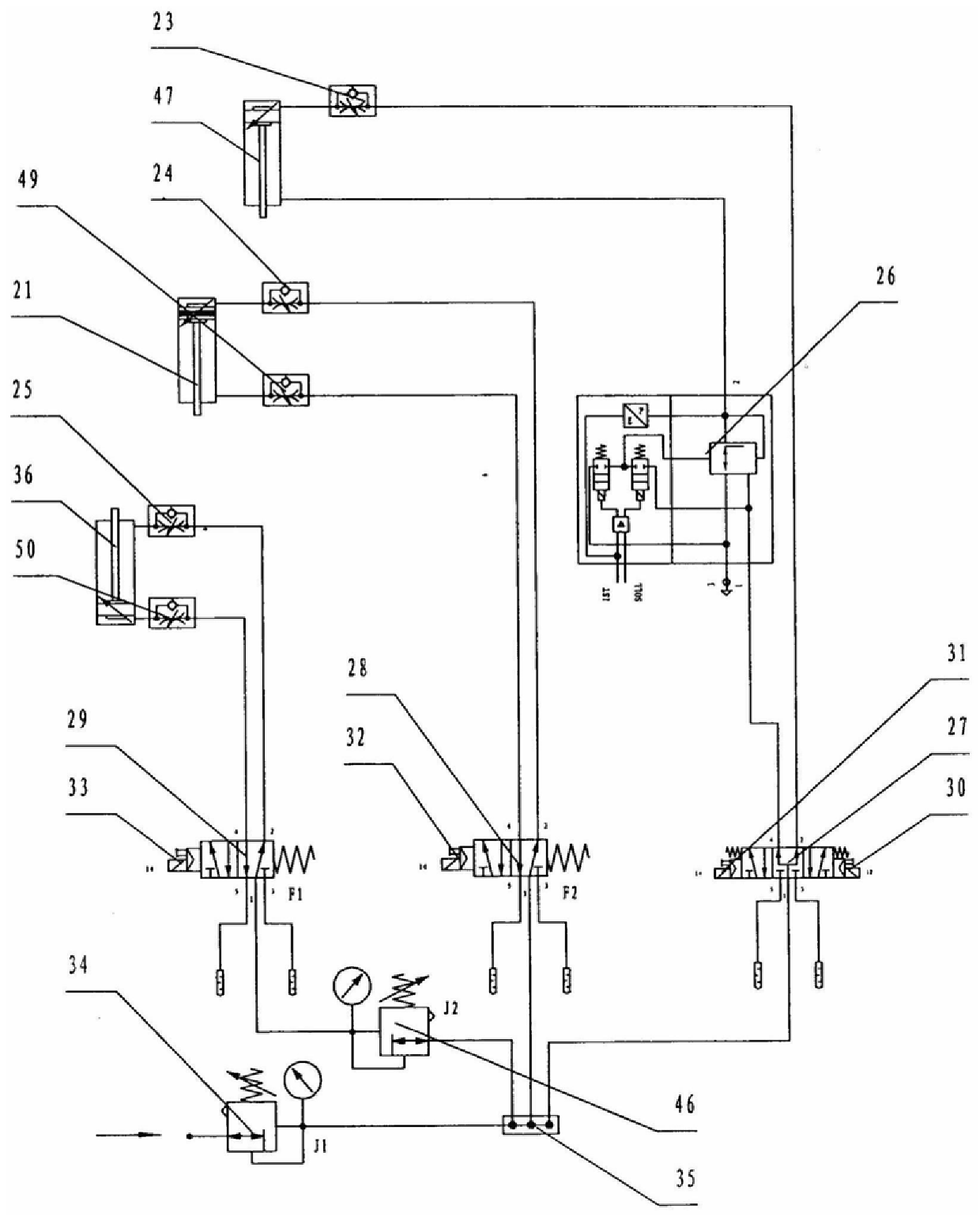

The invention belongs to the field of assembly of small-caliber bullets, and in particular relates to a screw-in type electric primer explosion-proof screwing machine used in the assembly of small-caliber bullets. A screw-in type electric primer explosion-proof tightening machine of the present invention includes a cartridge cup, a jacking mechanism, a positioning and clamping mechanism, a pit device for automatically pressurizing and searching for a screw-in type electric primer, an air circuit system, a control part and controlling software. The jacking mechanism of the screw-in electric primer explosion-proof screwing machine is installed on the machine base, the cartridge cup is located above the jacking mechanism, and the positioning and clamping mechanism, automatic pressurization and the pit device for finding the screw-in electric primer are located in the cartridge in turn. The top of the cylinder cups are installed on the rack. The air source, valve, air pipe and the pneumatic actuators of the above mechanical parts form an air circuit system. The control software is set in the controller of the control part, and the controller and the control software control the operation of the above-mentioned mechanical structure. The screw-in electric primer explosion-proof tightening machine of the present invention can automatically complete the screwing of the screw-in electric primer, it solves the problem of automatically finding the pit on the screw-in electric primer, and can ensure the precision control of the screw-in electric primer tightening depth , to ensure product quality, realize the separation of man and machine, and ensure the safety of production personnel.

Description

Screw-in electric bottom fire explosion-proof tightening machine technical field The invention belongs to the field of assembly of small-caliber bullets, and in particular relates to a screw-in type electric primer explosion-proof screwing machine used in the assembly of small-caliber bullets. Background technique The production of small-caliber ammunition is mostly manual assembly. The worker uses a vise to clamp the cartridge, and snaps the wrench with three claws into the three pits distributed at 120° on the front surface of the electric primer, and then rotates the wrench to press down while rotating. , to achieve the purpose of tightening the electric primer. This manual assembly method is not only labor-intensive for workers, but also the screw-in torque and screw-in depth cannot be controlled, and the dispersion is also large. If there is a slight carelessness in screwing in, the electric primer will explode, causing injury accidents. Contents of the invention ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F42C19/08B25B21/00

Inventor 苏泽胜周丽娟韩银泉翟大庆黄明康吴斌孔淼

Owner SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com