Ray-based dry type transformer winding material detection method and device

A dry-type transformer and detection method technology, applied in the direction of material analysis using radiation, can solve the problems of inability to distinguish winding coil materials, destructive detection, damage, etc., and achieve the effect of simple and easy-to-use equipment, simplified test conditions and requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

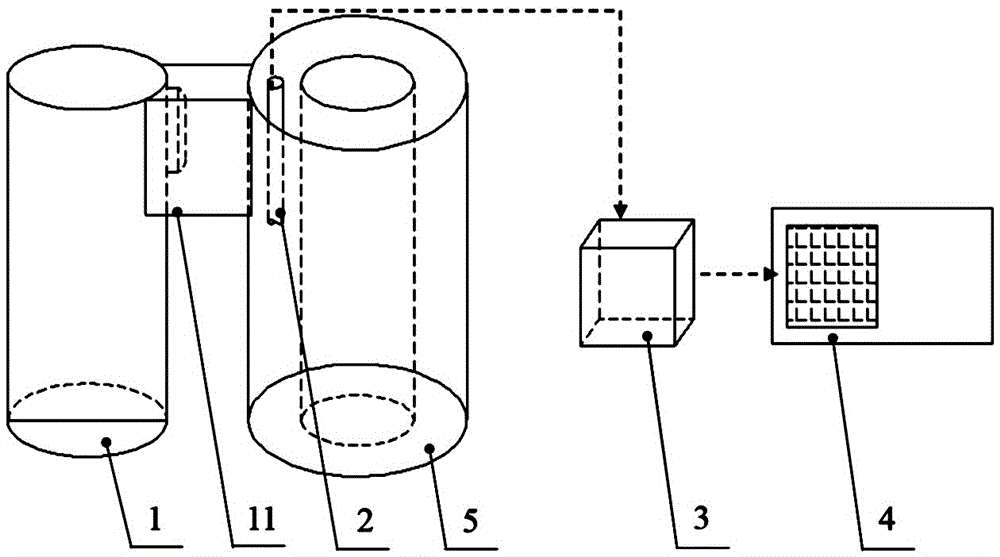

[0022] The steps of the ray-based dry-type transformer winding material detection method in this embodiment include:

[0023] 1) Radiation rays are emitted on one side of the winding of the dry-type transformer to be detected, and at the same time, the energy of the radiation rays after passing through the winding of the dry-type transformer to be detected is detected by a detector on the other side of the winding of the dry-type transformer to be detected;

[0024] 2) The winding material of the detected dry-type transformer is judged according to the energy change of the radiated rays before and after the winding of the detected dry-type transformer.

[0025] Using the ray-based dry-type transformer winding material detection method in this embodiment, the dry-type transformer winding can be detected, and the winding material of the detected dry-type transformer can be identified as copper or aluminum, and the design or technical agreement can be compared to find out whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com