Self-tension Synchronous Whell Shaft Single-side-fixing Device

A fixed device, self-tensioning technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of difficult to meet the volume and weight requirements of unmanned helicopters, achieve space and weight saving, strong Structural strength, the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

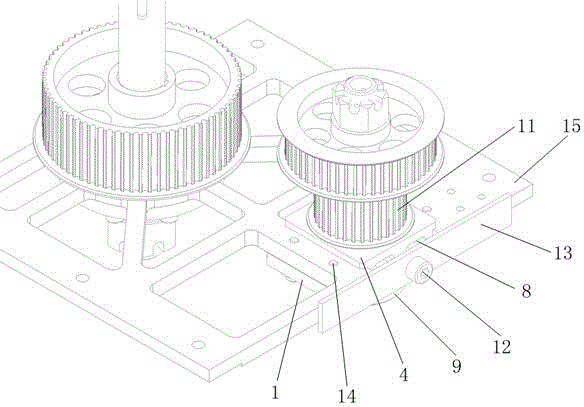

[0017] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

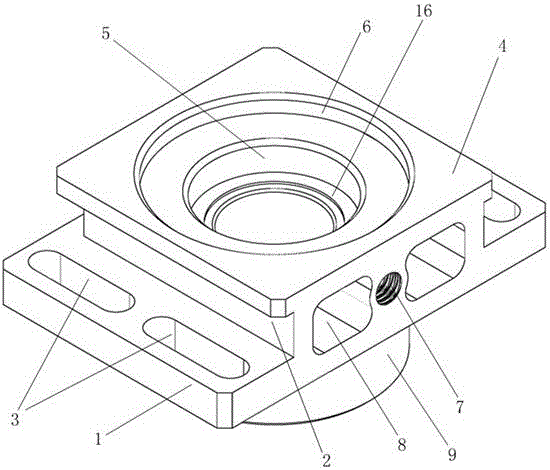

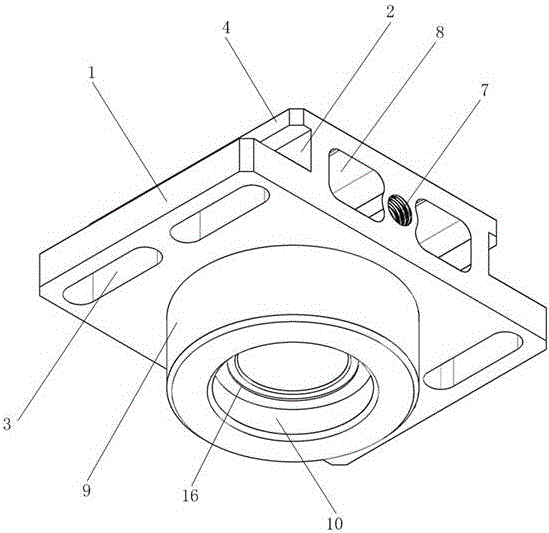

[0018] Such as Figure 1-3 As shown, the self-tensioning synchronous axle unilateral fixing device of the present invention includes: a fixing base plate 1 , a tensioning bolt 12 and a strip top plate 13 .

[0019] Wherein, a square bearing mounting block 4 is provided on the upper side of the fixed base plate 1; a chute 2 is provided on the left and right sides of the square bearing mounting block 4; a cylindrical bearing mounting block 9 is provided on the lower side of the fixed base plate 1 ; The fixed base plate 1, the square bearing mounting block 4 and the cylindrical bearing mounting block 9 are of an integrated structure; the center of the square bearing mounting block 4 is provided with a wheel shaft hole, and the wheel shaft hole runs through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com