Convenient segmented support method for mine slant chute

It is a convenient and sliding shaft technology, which is applied in the shaft lining, mining equipment, shaft equipment, etc. It can solve the problems of difficulty in pumice inspection, large exposed area of the surrounding rock of the shaft wall, and large slump of the surrounding rock of the shaft wall. The effect of safety benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

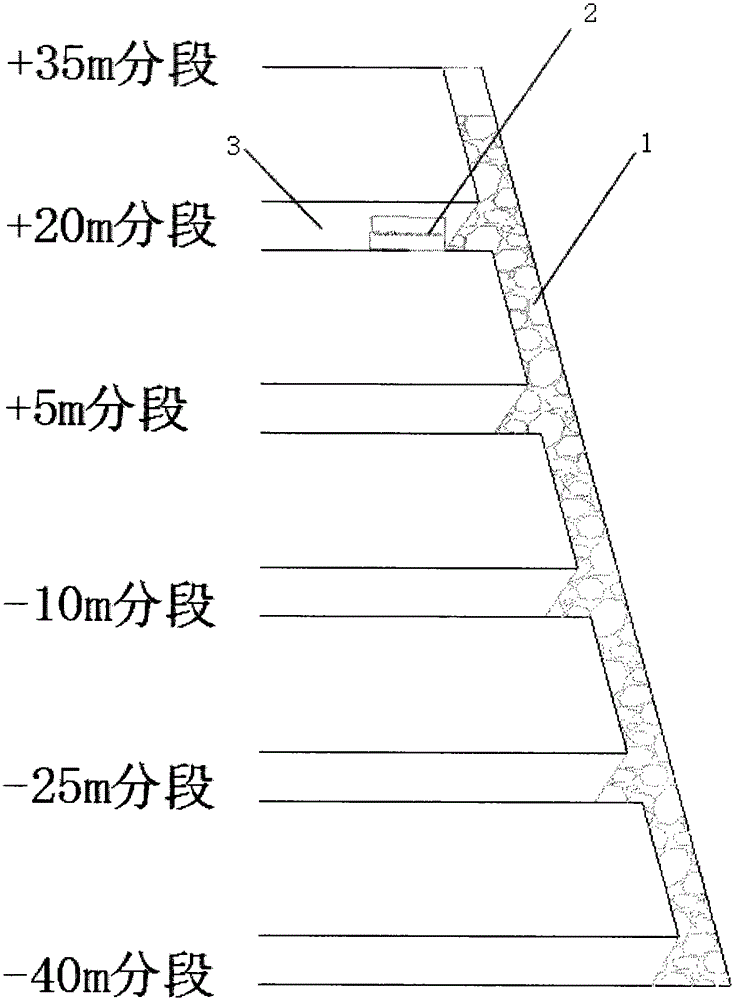

[0032] Such as figure 1 As shown, the height of a certain mine is 35m.

[0033] A convenient segmented support method for an inclined shaft in a mine, comprising the following steps:

[0034] (1), according to the actual construction situation, according to the existing mountain stability analysis method, the stability of the shaft wall of the chute is calculated and analyzed, and the support form is determined;

[0035] (2), at the wellhead of the inclined chute, excavate a chute connecting lane 3 every 15 meters (i.e., segmented, divided into +35m segment, +20m segment, +5m segment), the chute connecting lane 3 respectively It communicates with the inclined chute and the ground,

[0036] (3), fill the inclined chute with backfill ballast 1 until the surface of backfill ballast 1 is 2m away from the wellhead, lay planks on the upper surface of backfill ballast 1 in the well, and construction personnel step on the planks to carry out support construction operations;

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com