Luminescent plastics for televisions

A technology for televisions and plastics, applied in the field of plastics, can solve problems such as damage to physical and mental health, unsatisfactory environmental protection performance, etc., and achieve the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

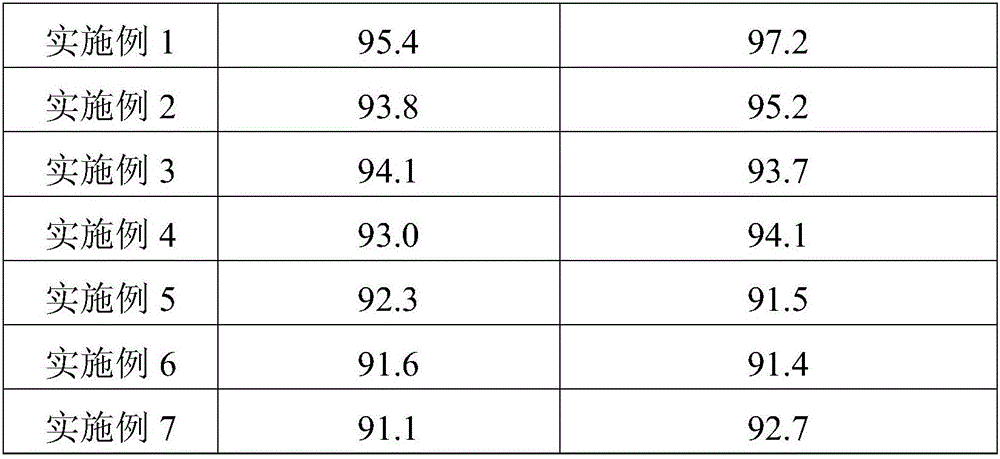

Embodiment 1

[0027] Luminous plastic raw materials for TV (parts by weight): 100 parts of ABS resin, 30 parts of luminous powder, 3 parts of mercaptan methyl tin, 3 parts of flame retardant, and 1.2 parts of antioxidant.

[0028] Described flame retardant is 1:1 by mass ratio by three (2-chloroethyl) phosphoric acid esters, phosphoric acid tris (butoxyethyl) esters, phosphoric acid tris (1-chloro-2-propyl) esters: 1 Stir to mix evenly to obtain.

[0029] The antioxidant is composed of N-isopropyl-N-phenyl-p-phenylenediamine, N-cyclohexyl-N'-phenyl-p-phenylenediamine, N,N-di-sec-butyl-p-phenylenediamine Stir and mix uniformly according to the mass ratio of 1:1:1.

[0030] Preparation of luminous plastic for TV:

[0031] Add each component into a high-speed mixer, control the speed at 350 rpm at room temperature, mix for 8 minutes, take it out and transfer it to a twin-screw extruder, the processing temperature of the twin-screw extruder is 145 ° C, and the speed of the main machine is 35...

Embodiment 2

[0033] Basically the same as Example 1, the only difference is that the flame retardant is stirred by tris (butoxyethyl) phosphate and tris (1-chloro-2-propyl) phosphate in a mass ratio of 1:1 Mix well to get. Obtain the luminous plastic for television set of embodiment 2.

Embodiment 3

[0035] Basically the same as Example 1, the only difference is that the flame retardant is stirred by tris (2-chloroethyl) phosphate and tris (1-chloro-2-propyl) phosphate in a mass ratio of 1:1 Mix well to get. Obtain the luminous plastic for TV set of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com