Method for vertical solar intensified deep biological drying of sludge

A biological drying and solar energy technology, applied in the fields of resources and the environment, can solve the problems of increasing the floor space of the solar drying device, the low energy utilization efficiency of the solar drying device, and the difficulty of continuous operation, so as to reduce the heat. The effect of escape, improving operating efficiency and stability, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

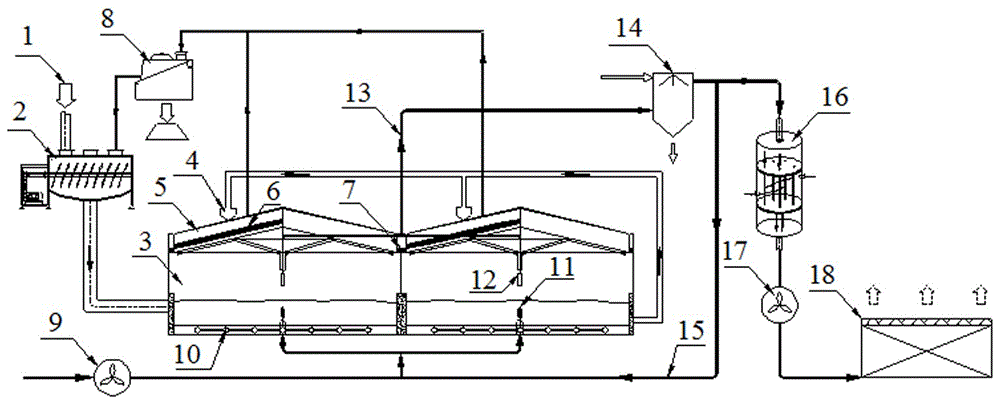

[0028] Such as figure 1 As shown, the vertical solar energy enhanced sludge deep biological drying system and method provided by the present invention can dry the dewatered sludge through the secondary vertical coupling process of biological drying and solar drying. machine 2, biological drying chamber 3, distributing machine 4, solar drying chamber 5, vibrating screen 8, blower 9, aeration system 10, temperature sensor 11, hydrogen sulfide sensor 12, gas collection system 13, gas scrubber 14, It consists of a gas circulation system 15, a heat exchange device 16, an induced draft fan 17 and an underground soil biological filter bed 18.

[0029] Wherein, an aeration system 10 is provided at the bottom of the biological drying chamber 3, and the biological drying chamber 3 performs biological drying on materials. The biological drying chamber 3 is provided with an aeration system 10 and a retractable temperature sensor 11 sleeve under the concrete floor to monitor the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com