Wind wave blocking type hybrid ship

A hybrid power, wind and wave technology, applied in the direction of the hull, ship propulsion, ship parts, etc., can solve the problems of insufficient weight of the hull, breakage in the middle of the hull, and low draft, so as to avoid water ingress in the hull, increase the service life, and reduce the usage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

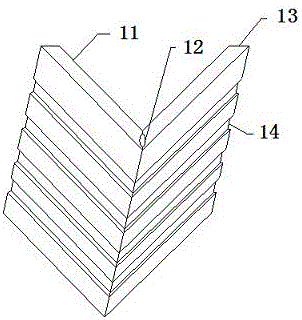

[0021] Specific embodiments: firstly, the operator checks the present invention to see if there is a defect. If there is a defect, it cannot be used. At this time, it is necessary to notify the maintenance personnel to carry out maintenance. If there is no problem, it can be used. When using, first The operator adjusts the water retaining plate 11 and the water retaining plate 2 13 to a suitable angle through the rotating shaft 12, and installs the water retaining plate 11 and the water retaining plate 2 13 on the hull 3. When the ship sails, the water retaining plate 1 11 and water retaining plate two 13 greatly reduce the resistance of water to hull 3, and water filtering groove 14 accelerates the flow of water, makes hull 3 keep steady, and the present invention has added water retaining plate one 11, rotating shaft one 12, water retaining plate two 13 and Filter tank 14, this design solves the problem that original ship's water retaining effect is poor, and hull 3 sailing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com