Plastic pipe extrusion equipment heat-exchange circulatory system and application method thereof

A technology of extrusion equipment and plastic pipes, which is applied in the field of heat exchange circulation system of plastic pipe extrusion equipment, can solve the problems of insufficient drying of extruded materials, waste of power resources and energy, and quality problems, so as to avoid heat loss and save energy. Energy and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

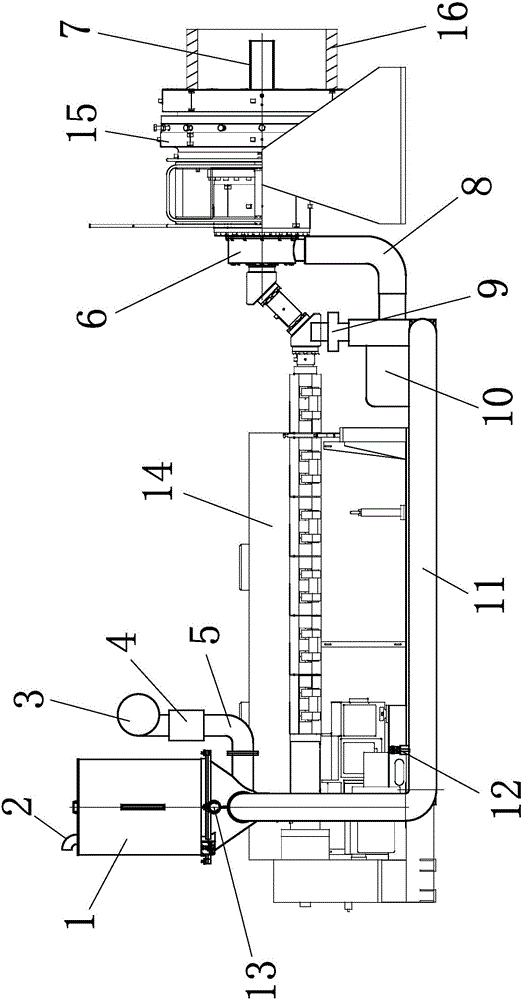

[0018] Embodiment 1: as figure 1 As shown, a heat exchange circulation system of plastic pipe extrusion equipment includes a single-screw plastic extruder 14 and a plastic extrusion die body 15, and the input end of the single-screw plastic extruder is connected with a dryer barrel 1 to dry An auxiliary heating cylinder 5 and an auxiliary fan 3 are connected to the barrel of the machine, a suction fan 10 is arranged at the mold body of the plastic extrusion mold, and a heat exchange suction pipe 7 is arranged at the axis of the mold body of the plastic extrusion mold. Trachea links to each other with suction blower by front suction pipe 8, and the output end of suction blower communicates with dryer barrel through hot blast air delivery pipe 11. A heat exchange gas collection box 6 is arranged between the heat exchange suction pipe and the front suction pipe. The suction fan place is provided with a noise reduction device 9 . A pressure relief valve 12 is arranged on the hot...

Embodiment 2

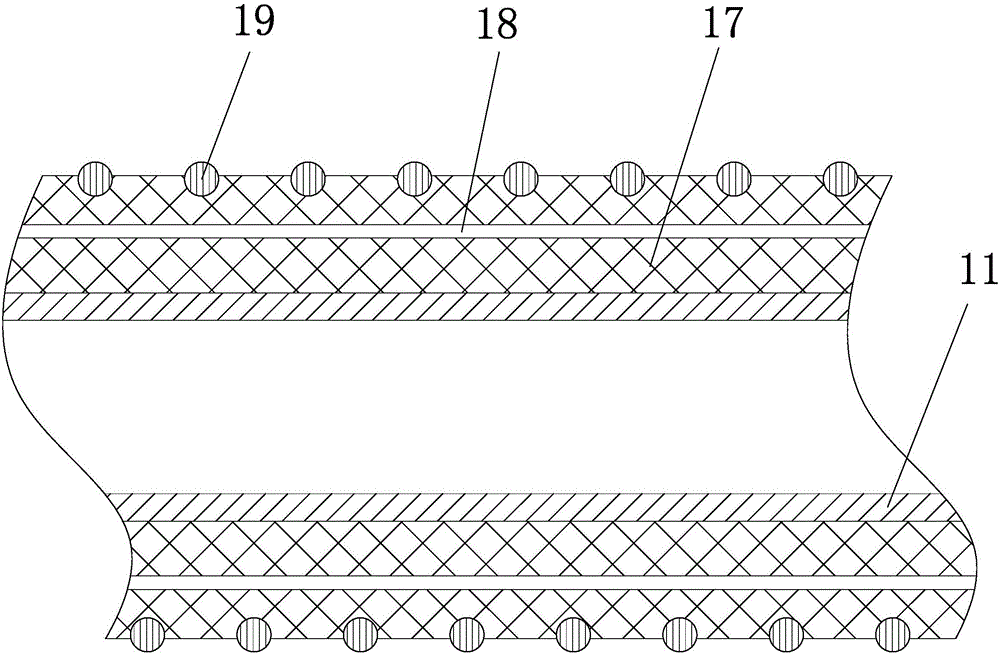

[0021] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as figure 2 As shown, the outer side of the hot air supply pipe is provided with a thermal insulation cotton cover 17, and the inside of the thermal insulation cotton cover is provided with several elastic positioning lines 18. The elastic positioning lines are parallel to the axial direction of the hot air supply pipe, and several elastic positioning lines are distributed around the axis of the thermal insulation cotton cover. An elastic backguy 19 is arranged on the outer side of the thermal insulation cotton cover, and the elastic backguy is helical and embedded in the outer surface of the thermal insulation cotton cover. The thermal insulation cotton cover is wrapped on the outside of the hot air supply pipe, and the thermal insulation cotton cover can keep the hot air supply pipe warm, and can prevent the condensation water on the surface of the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com