Special flexible punching machine

A punching and special machine technology, applied in the field of refrigerator liner production and processing, can solve the problems of low labor intensity and reduction of operators, achieve the effects of safe and efficient operation, reduce operating procedures, and solve the problem of punching and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described below in conjunction with specific embodiments.

[0017] Such as Figure 1 to Figure 3 As shown, it is a flexible punching machine according to the present invention, which includes a box body, a connecting plate 20 is arranged on the side wall of the box body 10, and a control program box 30 is arranged on the connecting plate 20;

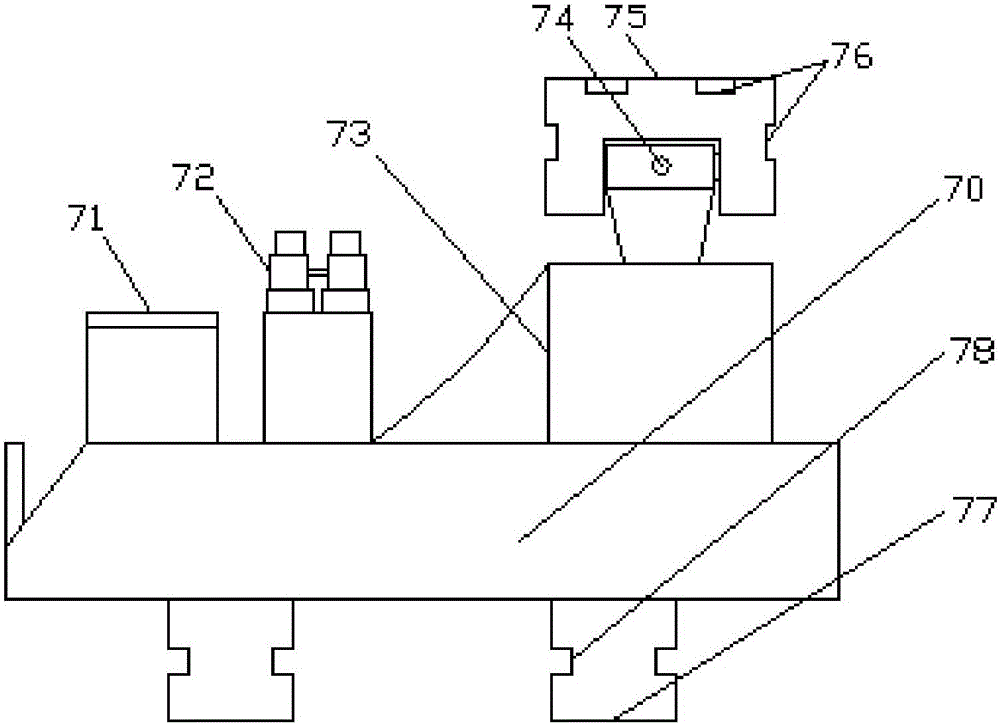

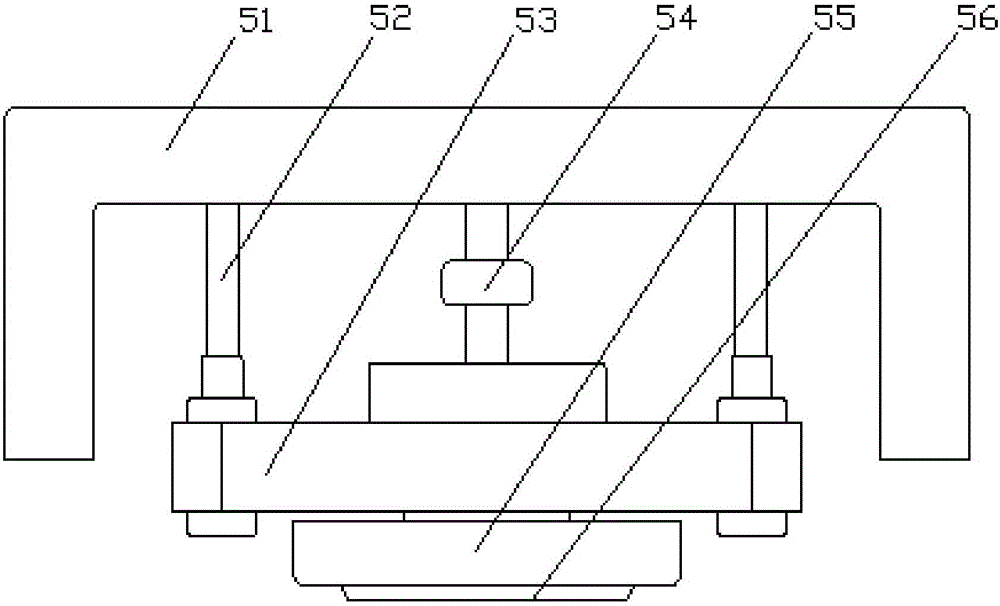

[0018] The casing 10 is provided with a punching area 40, the top of the punching area 40 is provided with a first punching mechanism 50, the side wall of the punching area 40 is provided with a wedge-shaped installation template 41, and the wedge-shaped installation template 41 is provided with a second punching mechanism 50. The punching mechanism 60 is provided with a slide rail 42 at the bottom of the punching area 40, and the slide rail 42 is provided with a sliding seat 70 for use in cooperation. The sliding seat 70 is respectively provided with a positioning mechanism 71, a scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com