Efficient stacking-cutter device and stacking-cutter process thereof

A high-efficiency, round-knife technology, used in metal processing, other household appliances, flat products, etc., can solve the problems of inconvenient collection of waste, low efficiency, slow speed, etc., to achieve the effect of improving efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

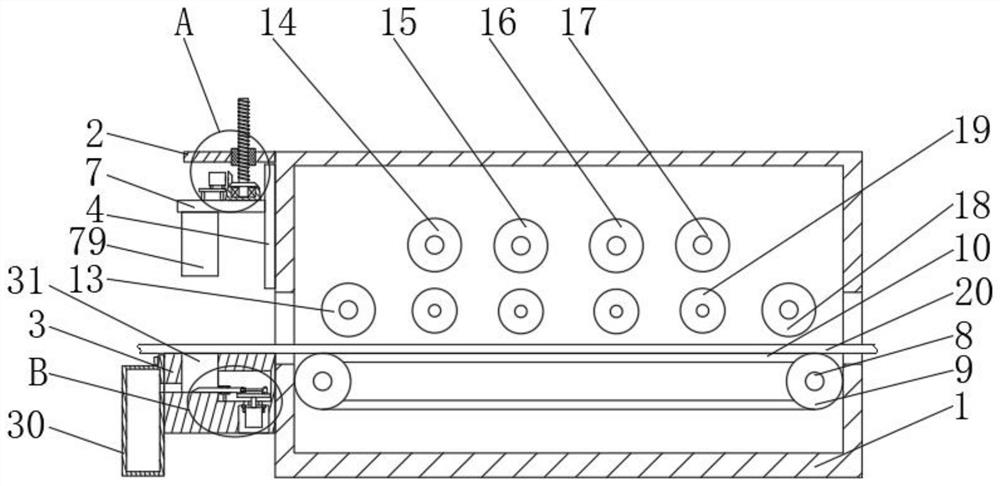

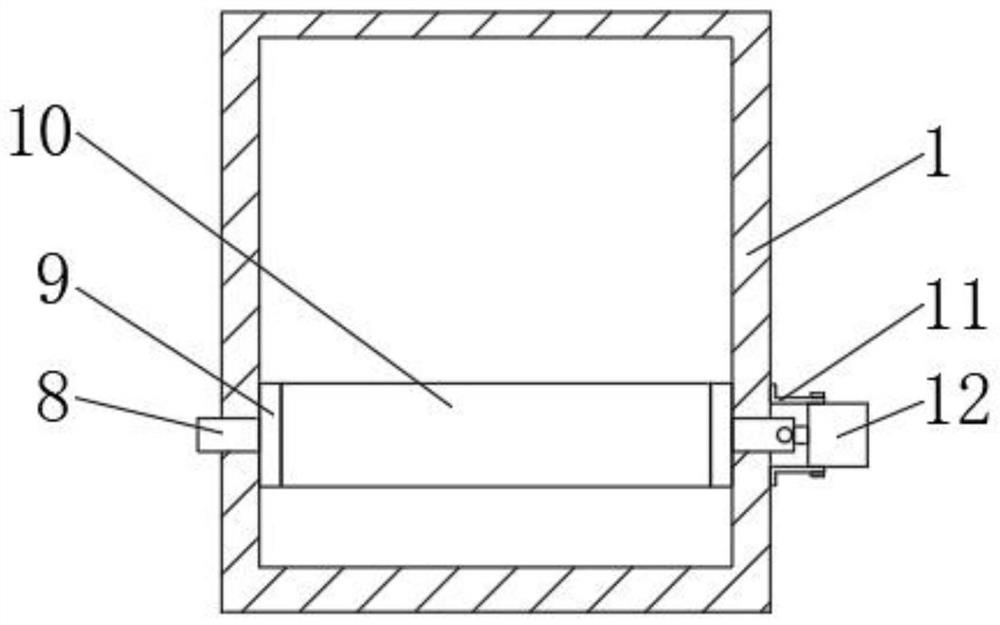

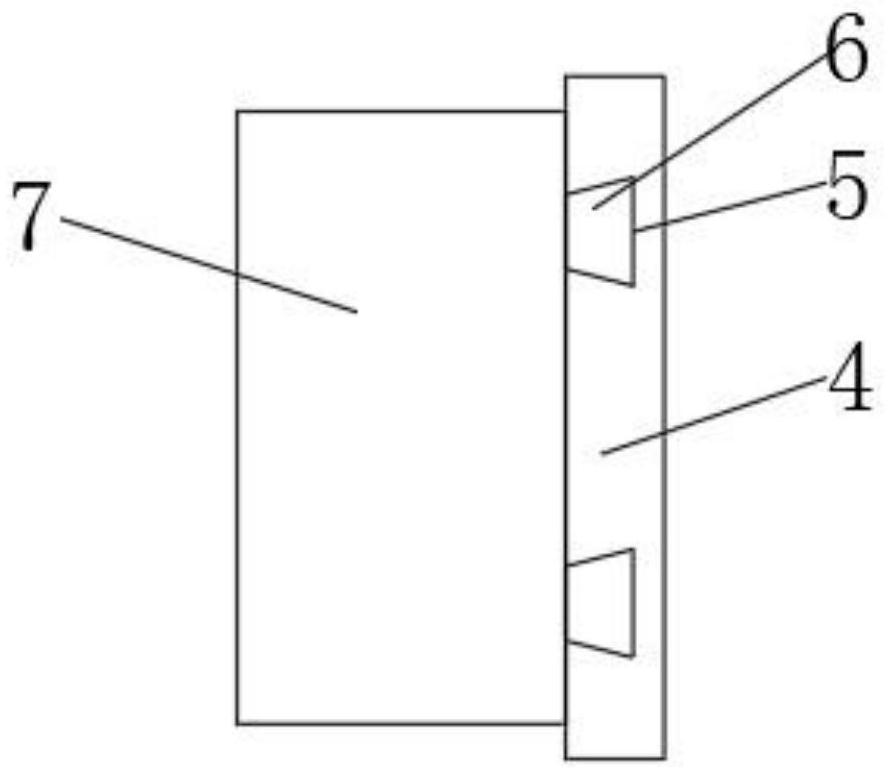

[0033] A high-efficiency knife stacking device and its stacking process, including a box body 1, a fixed plate 2, a cutting table 3, a slide plate 4, a dovetail groove 5, a dovetail block 6, a moving plate 7, a drive shaft 8, a roller 9, and a conveyor belt 10 , the left end of the box body 1 is fixedly connected with a fixed plate 2, the left end of the box body 1 is fixedly connected with a cutting table 3, the left end of the box body 1 is fixedly connected with a slide plate 4, and the left end of the slide plate 4 is slidably connected There is a moving plate 7, and the inside of the box 1 is connected with two symmetrically distributed drive shafts 8, the outer side of the drive shaft 8 is fixedly connected with a drum 9, and the outer side of the drum 9 is sleeved with a conveyor belt 10. Two symmetrically distributed motor frames 11 are fixedly connected to the outside of the box body 1 .

[0034] Wherein, the inside of the box body 1 is connected with a round knife 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com