Punch for machining irregularly-shaped hole at thread of thin-wall part

A technology of thin-walled parts and special-shaped holes, which is applied in the field of punches for processing special-shaped holes at the threads of thin-walled parts, to reduce cutting resistance and solve punching problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

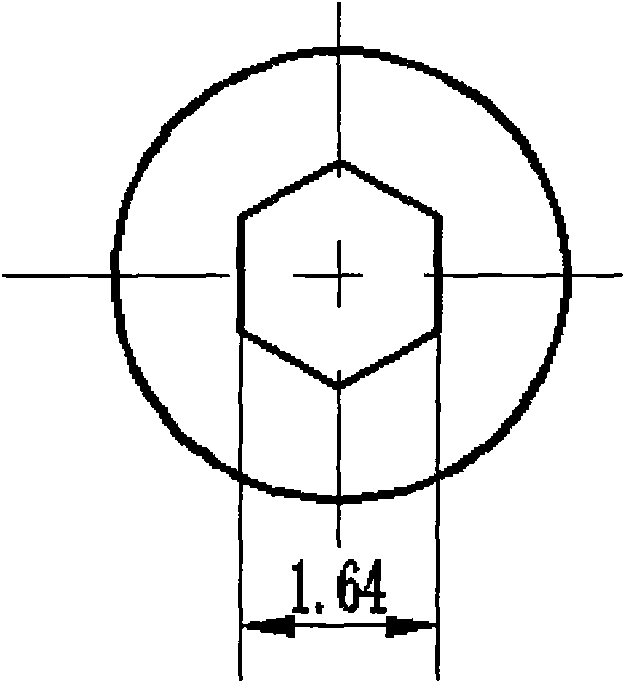

[0014] To process a countersunk screw, the countersunk screw has a hexagonal hole in the thread, the small diameter of the thread and the wall thickness of the hexagonal hole are only 0.53mm~0.58mm, the thread specification is 138-40UNJF-3A MOD, the hexagonal hole of the hexagonal The opposite side size is 1.63 -0.02 , with a depth dimension of 3.0 +0.2 ,. This part is a thin-walled part with a special-shaped hole in the thread, and to process this part, the novel punch of the invention needs to be used.

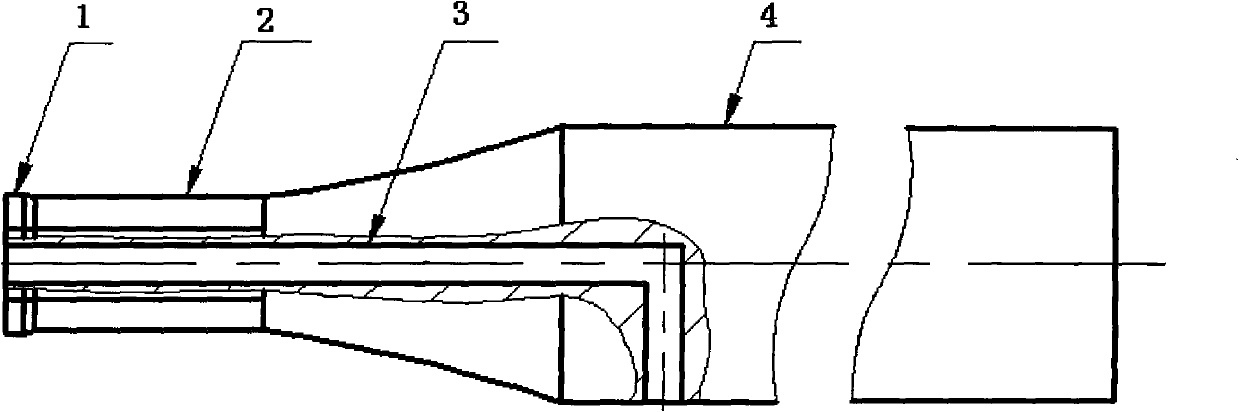

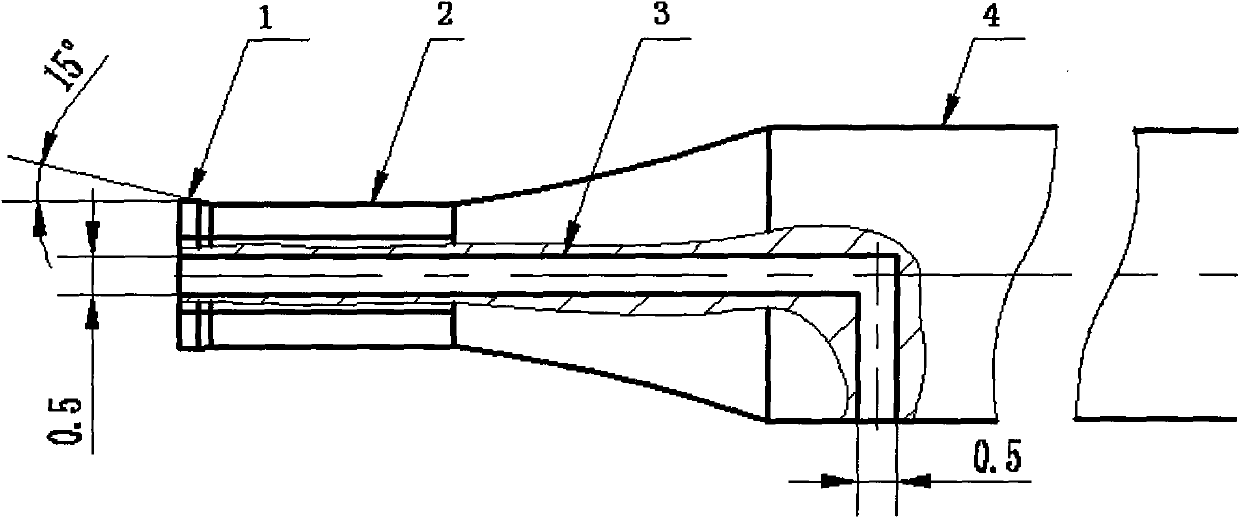

[0015] Since the special-shaped hole of the part to be processed is hexagonal, a hexagonal punch is designed (see attached figure 1 ), the ligament part of the punch is hexagonal, and the end face of the ligament part of the punch is perpendicular to the center line of the clamping part of the polished rod. The side diameter is 1.64mm and the length is 1mm. Behind the ligament part there is a avoidance part with a diameter of 1.60mm. The ligament part and the avoidance pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com