Workpiece Supplying Device, Picking Device, Timepiece Assembling Apparatus, And Picking Method

A supply device and pick-up device technology, applied in conveyor control devices, metal processing, manufacturing tools, etc., can solve problems such as difficult to correctly select, difficult to correctly identify the position, posture, and complex movements of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

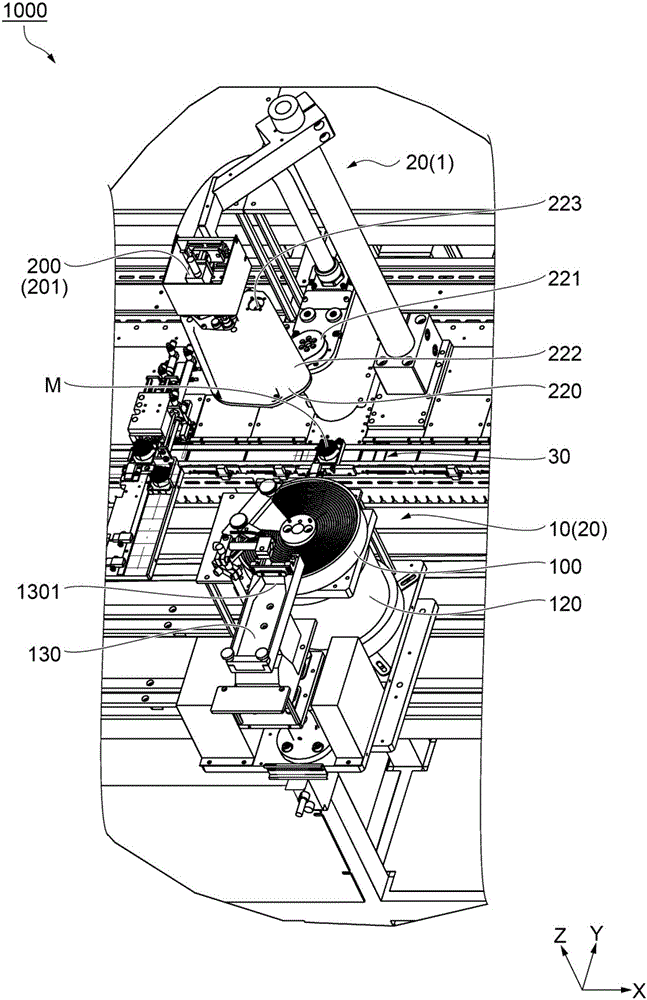

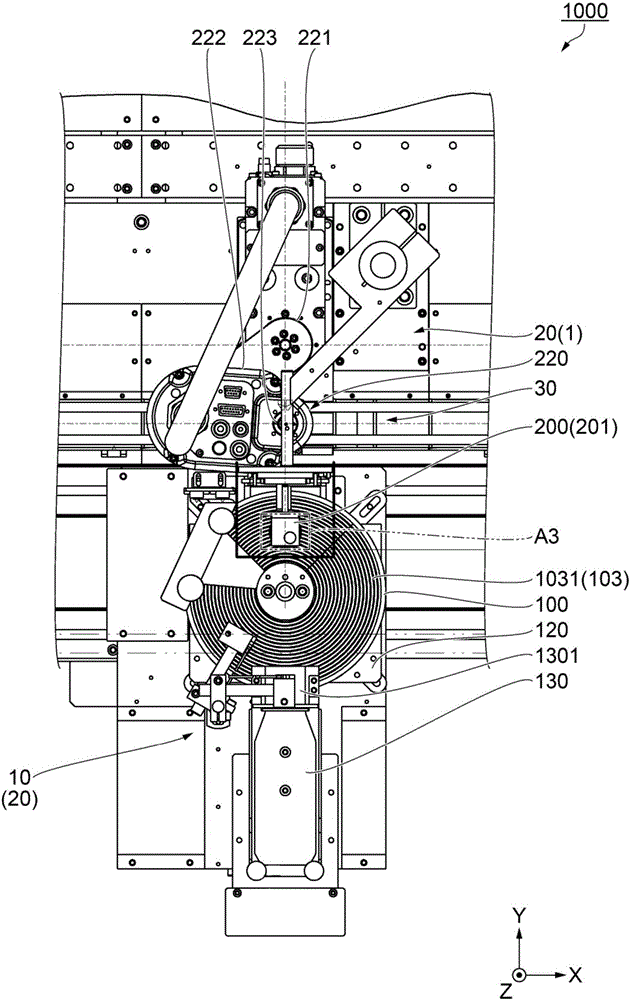

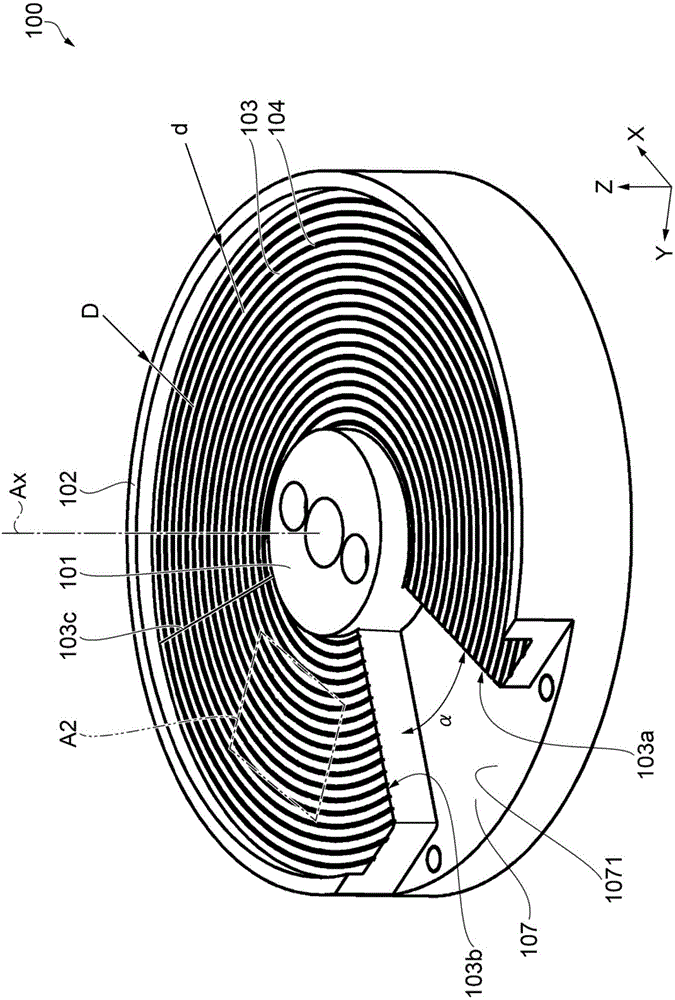

[0039] figure 1 It is a perspective view showing the timepiece assembly device 1 of this embodiment. figure 2 It is a top view of the watch assembly device 1 viewed from above. refer to figure 1 , figure 2 , the structure of the watch assembly device 1 will be schematically described.

[0040] The watch assembly device 1 of the present embodiment is used as a device responsible for one manufacturing process (assembly process) in a production line (watch assembly line 1000 ) for mechanically assembling a watch having a plurality of manufacturing processes. Furthermore, the watch assembly apparatus 1 repeatedly executes the work W ( Figure 8 ), and use image recognition to grasp the supplied workpiece W by the selection unit 220 and move the workpiece W to a desired position.

[0041] In addition, for convenience of description, the drawing which demonstrates this embodiment is shown using the XYZ rectangular coordinate system. In detail, in figure 1 In the drawing, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com