Axle housing body straight slit automatic welding production line and control method thereof

An automatic welding and production line technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unstable welding quality, low degree of automation, and large number of workers, so as to improve welding quality and automation degree High, improve the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

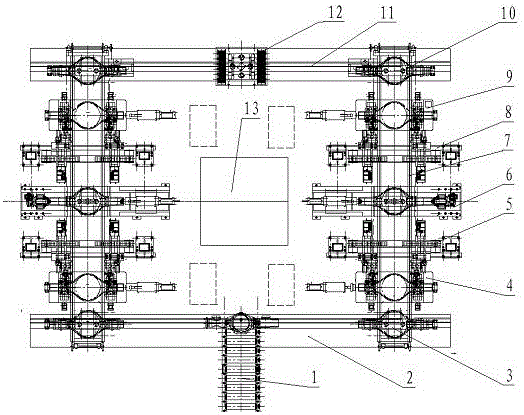

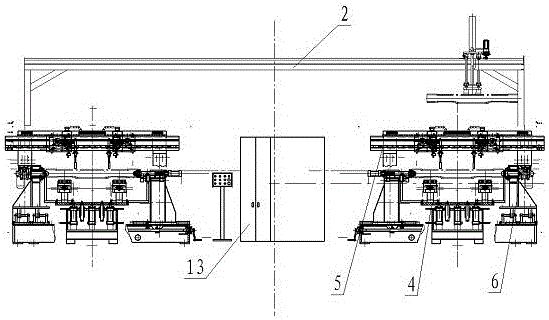

[0025] Embodiment 1, refer to figure 1 , 2 . The waiting station 10 and the chain plate conveying device 7 are combined to form a welding line. The welding station is equipped with gun cleaning, wire cutting, and silicone oil spraying devices. The chain plate conveying device 7 is driven by a motor to drive the sprocket chain to rotate the workpiece from the pre-release station 3 to Unloading waits for automatic conveying between stations 10; there are two welding lines, each welding line is equipped with two welding machines, and each welding machine is equipped with two welding machines; the feeding roller table 1 and the axle housing feeding air The loading line is composed of the transfer line and the magnetic suction lifting transport trolley 2; the magnetic suction loading hoisting transport trolley 2 transfers the workpiece from the loading roller table 1 to the pneumatic lift after being sucked by the magnet and then moved along the axle housing in the air The line i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com