Method for realizing multiple resistance values of electronic cigarette atomizing heating wires and arrangement structure

A technology of electronic smog and layout structure, which is applied in the direction of ohmic resistance heating parts, tobacco, smoker's supplies, etc. It can solve the problems of not achieving effective docking, not achieving the heating effect, and not ensuring that the power supply parameters match each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

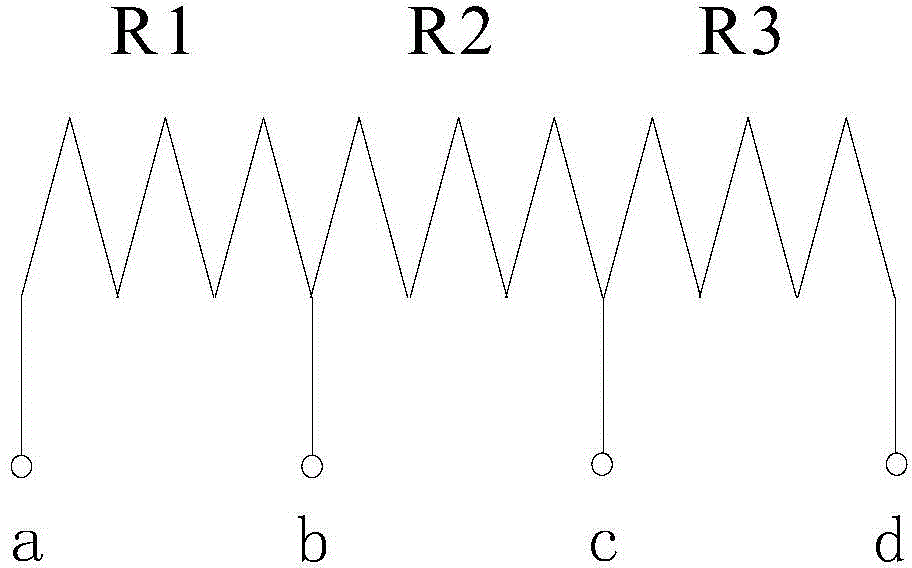

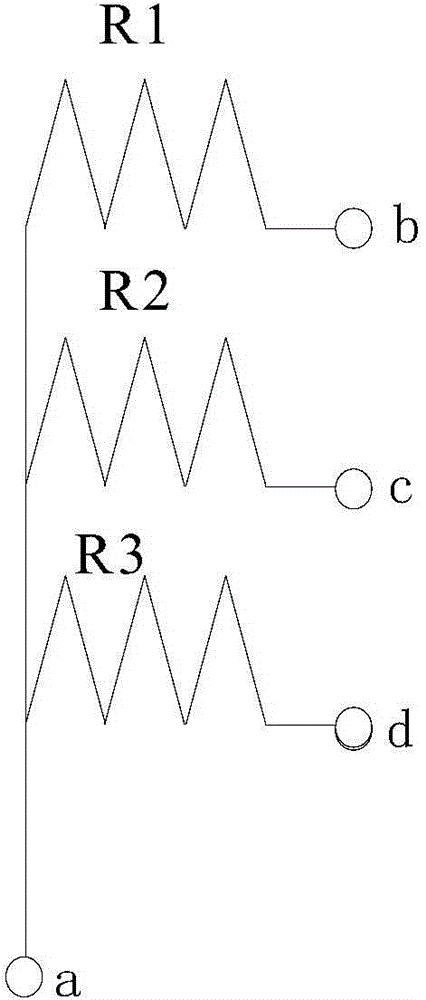

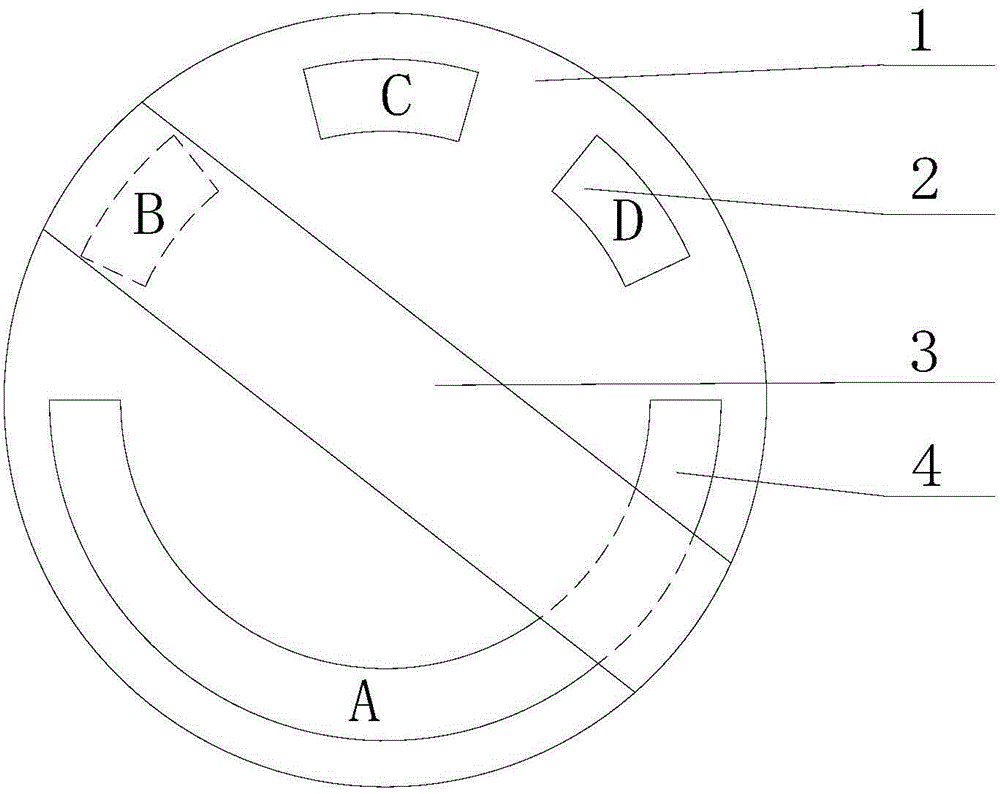

[0029] Such as figure 1 , image 3 As shown, in this embodiment, heating resistance wires with different resistance values are connected in series, and the resistances R1, R2, and R3 are respectively heating resistance wires with different resistance values. Since they are connected in series, a whole wire can be used. The heating resistance wire extended in a spiral shape leads out lead wires corresponding to different powers according to different parts of the heating resistance wire. Among them, the R1 section of the heating resistance wire is 0.5 ohms, corresponding to the space between ab; the R2 section is 1.0 ohms, corresponding to the space between bc; the R3 section is 1.5 ohms, corresponding to the space between cd. If it is set that the three groups of resistance wires all use the same common lead-out line, lead-out line a can be used, and the corresponding relationship of the other lead-out end is that R1 corresponds to b, R2 corresponds to c, and R3 corresponds...

Embodiment 2

[0041] In this embodiment, the heating resistance wires connected in series in Embodiment 1 are changed to heating resistance wires connected in parallel, wherein the heating resistance wires connected in parallel are provided with a common lead-out a and three lead-outs b, c, and d respectively, so that the heating resistance wires can be connected in parallel The heating resistance wires connected in parallel can produce the following multiple connection methods, such as connecting the common end a to one end of the heating power supply circuit, and connecting the other end to b, c, and d respectively to generate three different powers, and connecting the three sets of heating resistance wires Four combinations of bc, cd, bd, and bcd will be produced after two-two parallel connection and three-group parallel connection respectively, so this parallel connection can produce seven different power connection effects.

[0042] Thus if Figure 4 As shown, the difference between it...

Embodiment 3

[0045] On the basis of the above, this embodiment further adapts to the needs of the electronic smog core, and adopts the scheme of setting double wires in parallel, except that the parallel double wires use electric heating with different resistance values, and the connection scheme uses the connection method of the present invention , when the resistances of 1 ohm and 2 ohms are set in parallel, the resistance value of the heating resistance wire can be switched between 2 / 3, 1 and 2, and thus can basically adapt to different electronic cigarette heating control circuits. Due to the reduction in the number of heating resistance wires, it is easier to install on the vaping core of the electronic cigarette.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com