Flexible circuit board and manufacturing method thereof

A technology of flexible circuit boards and manufacturing methods, which is applied in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc., can solve problems such as monopoly and high material costs, and achieve ultra-low loss signal transmission, reduce Manufacturing cost, effect of improving transmission quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the flexible circuit board and its manufacturing method of the present invention will be detailed below with reference to the drawings and preferred embodiments. described as follows.

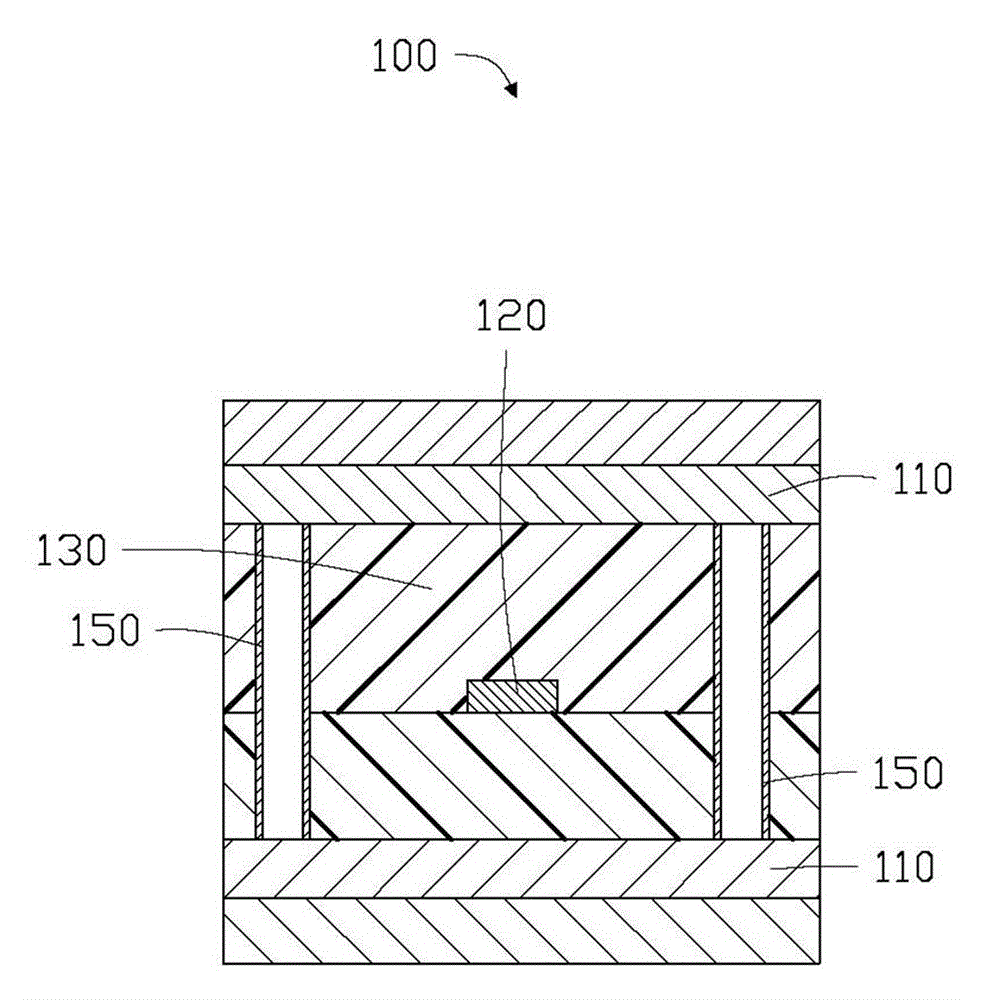

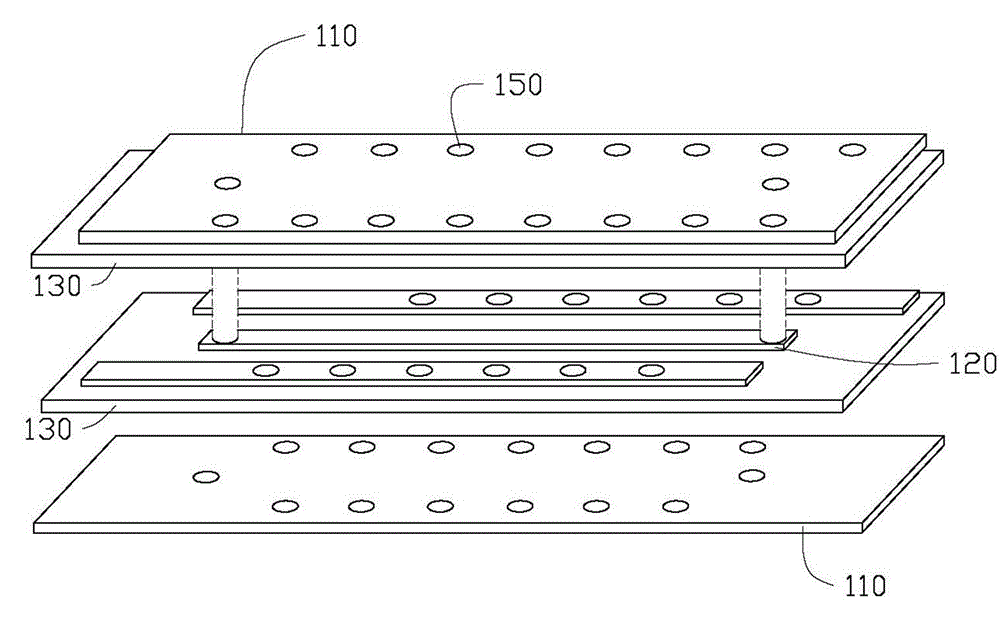

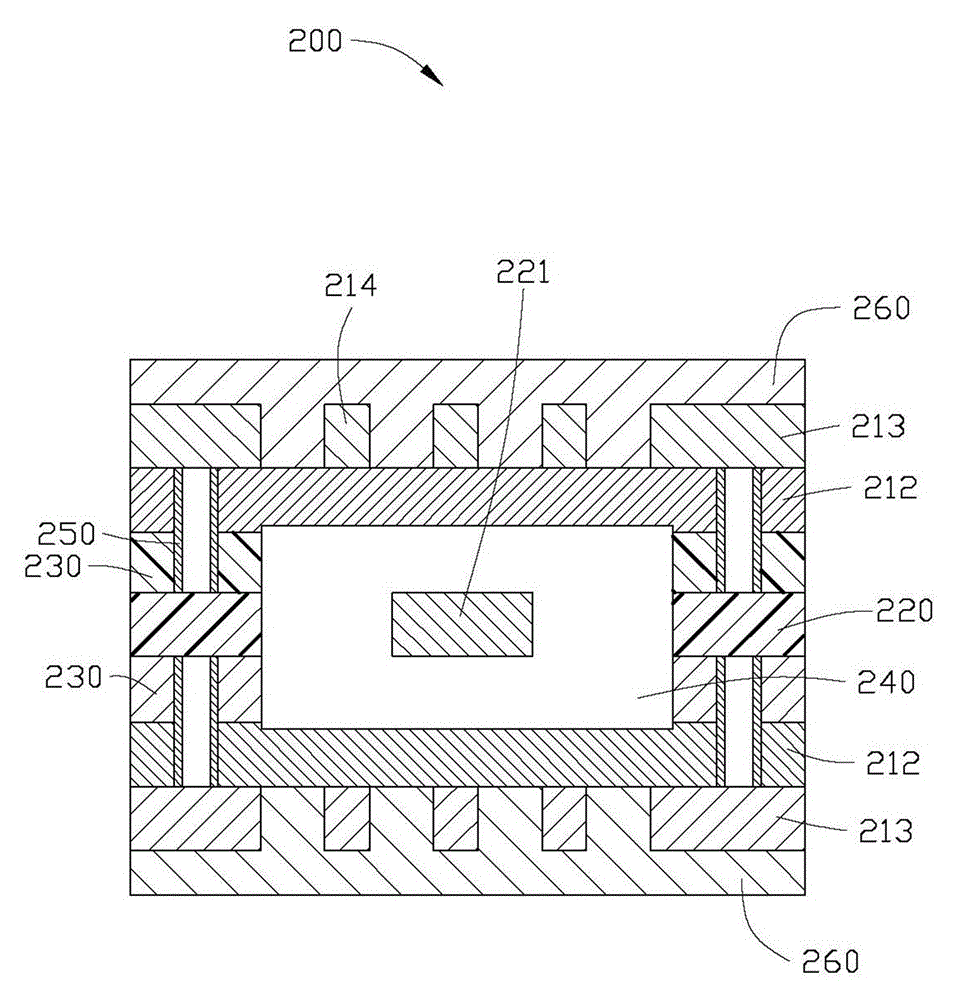

[0028] The first embodiment of the present invention discloses a flexible circuit board 200 that uses air as a dielectric layer to cover the linear signal line 221 so that the linear signal line 221 is in a suspended state. See image 3 As shown, it is a schematic cross-sectional view of the flexible circuit board 200. Figure 4 Is a schematic diagram of the flexible circuit board 200 from the inside to the outside of the circuit pattern, adhesive glue and copper-clad substrate, Figure 5 Middle (A)-(F) are schematic cross-sectional views of each step of the manufacturing method of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com