Frequency-flicker-free LED filament lamp

An LED filament lamp, no stroboscopic technology, which is applied in the use of semiconductor lamps, cooling/heating devices of lighting devices, lighting and heating equipment, etc. The effect of small size, simple circuit structure and high constant current precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

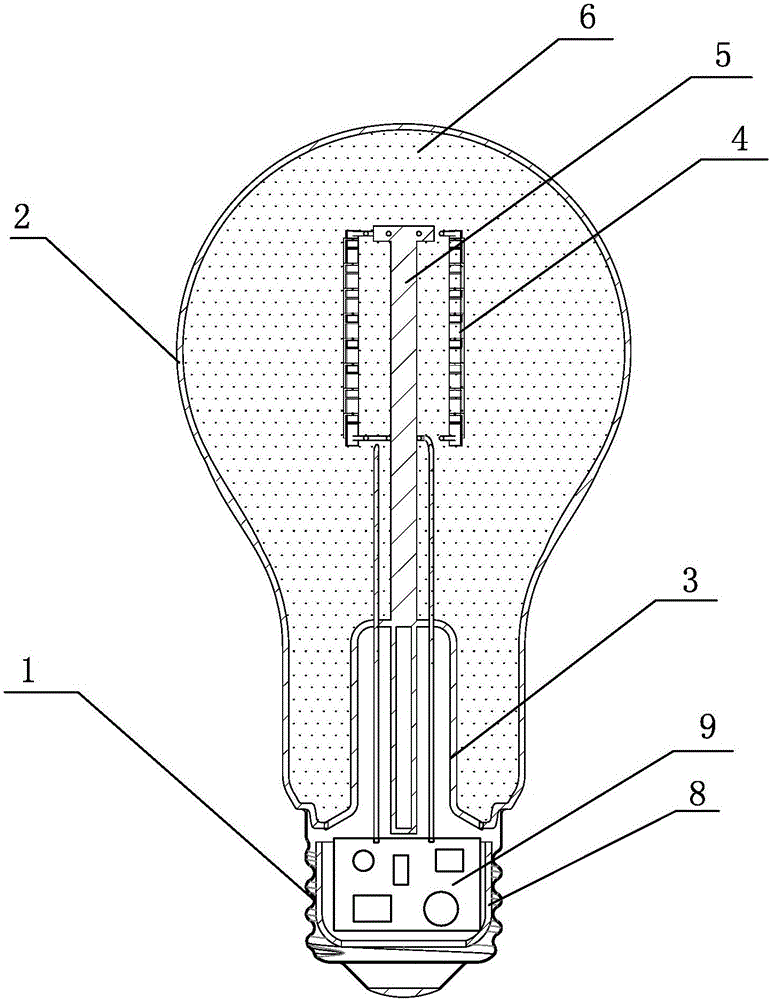

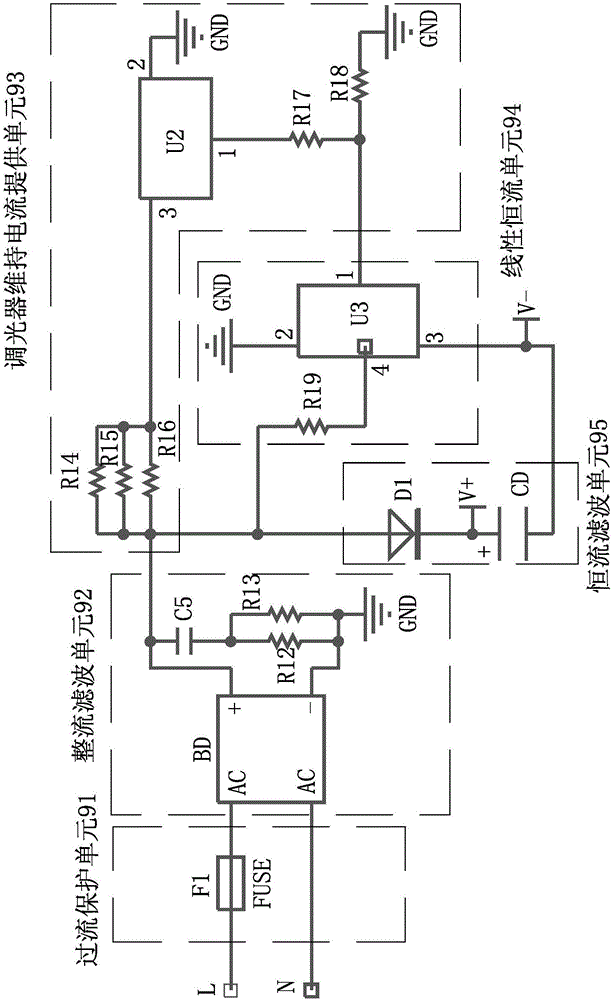

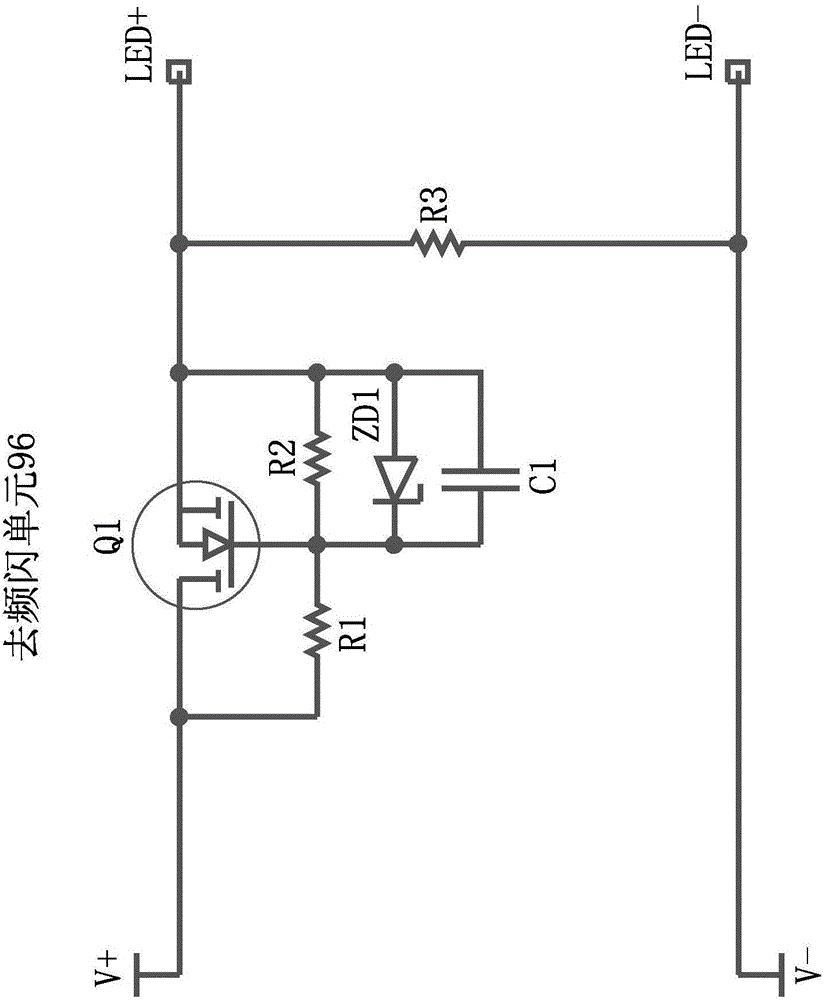

[0023] A kind of flicker-free LED filament lamp that present embodiment proposes, such as figure 1 , figure 2 and image 3 As shown, it includes a metal lamp cap 1, a glass bulb 2, a linear constant current driving power supply 9 arranged in the inner cavity of the metal lamp cap 1, a stem 3, an LED illuminant 4, a dimmer (not shown in the figure) Out), the top of the stem 3 is provided with a bracket 5, the LED illuminant 4 is installed on the bracket 5, the stem 3 loaded with the LED illuminant 4 is placed in the glass bulb 2, and forms a sealed seal with the glass bulb 2 Cavity 6, the airtight cavity 6 is filled with dry air, inert gas (such as nitrogen, argon, etc.) The drive power 9 in the inner cavity of the metal lamp cap 1 is connected, the metal lamp cap 1 and the glass bulb 2 are bonded and fixed, and the drive power 9 is maintained by an overcurrent protection unit 91, a rectification filter unit 92, and a dimmer connected to the dimmer. A current supply unit 93...

Embodiment 2

[0027] The flicker-free LED filament lamp proposed in this embodiment has the same other structures as the flicker-free LED filament lamp in Embodiment 1, except that the flicker-removing unit 96 is a flicker-removing circuit using a chip. Such as Figure 4 As shown, the anti-flicker circuit using the chip includes the first constant current chip U1 of the model YK3123, the fourth resistor R4, the fifth resistor R5, the sixth resistor R6, the seventh resistor R7, the eighth resistor R8, and the ninth resistor R9, the tenth resistor R10, the eleventh resistor R11, the second capacitor C2, the third capacitor C3 and the fourth capacitor C4, the first pin of the first constant current chip U1 is connected to one end of the fifth resistor R5, the first constant current The second pin of the flow chip U1 is respectively connected to one end of the sixth resistor R6, one end of the seventh resistor R7, one end of the eighth resistor R8, one end of the ninth resistor R9 and one end o...

Embodiment 3

[0029] A flicker-free LED filament lamp proposed in this embodiment further improves the structure of the flicker-free LED filament lamp in embodiment 1 or embodiment 2, see figure 1 That is, a heat dissipation structure capable of effectively dissipating heat to the driving power supply 9 is also added. The heat dissipation structure is a heat dissipation layer 8 formed by a layer of heat dissipation material wrapped outside the surface of the driving power supply 9. The driving power supply 9 wrapped with the heat dissipation layer 8 is placed on the metal In the inner cavity of the lamp cap 1, the heat dissipation layer 8 is in contact with the inner wall of the metal lamp cap 1, so that the heat of the driving power supply 9 is transferred to the metal lamp cap 1 through the heat dissipation layer 8, and the heat dissipation material is heat dissipation mud or heat dissipation glue. The heat of the heat can be transferred to the metal lamp holder 1 through the heat-conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com