Constant outlet temperature, pressure type flooded heater

An outlet temperature and heater technology, which is used in ohmic resistance heating parts, electric heating devices, electrical components, etc., can solve the problems of difficult to achieve thermal balance effect and affect the control accuracy of working fluid state, and achieve simple structure, simple manufacturing, To achieve the effect of pressure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and implementation the present invention will be further described.

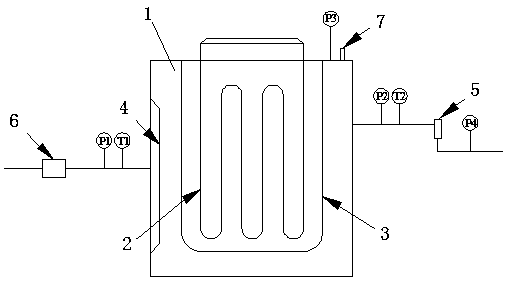

[0011] Such as figure 1 As shown, the fixed outlet temperature and pressure flooded heater of the present invention includes: a heater shell 1, an electric heating wire 2, a mass flow meter 6, an electronic expansion valve 5, a baffle plate 4, a molecular sieve 3, and a safety valve 7, and platinum resistance for measuring temperature, pressure transmitter for measuring pressure parameters. The heater shell 1 has a cylindrical structure, and is connected to the electric heating wire 2 through a flange. Inside the heater shell 1, a baffle plate for uniform heating of the working fluid and a molecular sieve 3 for preventing residues from entering the working medium are respectively arranged. A safety valve 7 is installed on the top of the heater housing 1 to prevent the internal pressure of the housing from being too high to affect the heating of the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com