Full-automatic crystalline silicon solar cell quality testing machine

A technology for solar cells and quality testing, applied in semiconductor/solid-state device testing/measurement, circuits, electrical components, etc., can solve the problems of uneven adhesion of tape, distorted test results, and contamination of silicon wafers to be tested, etc. The effect of simplicity, low manufacturing cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

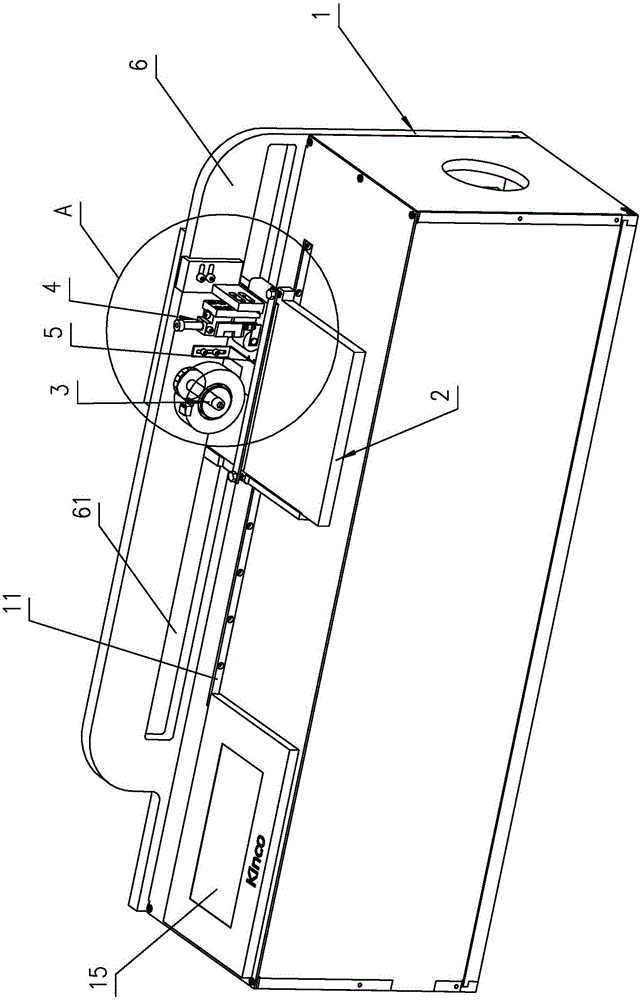

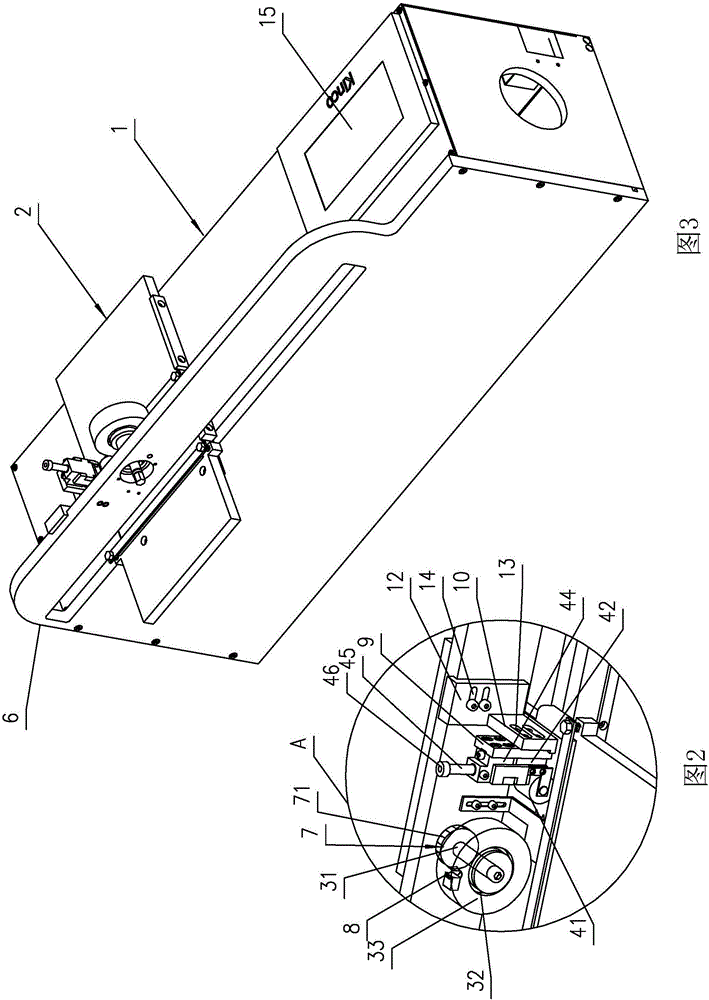

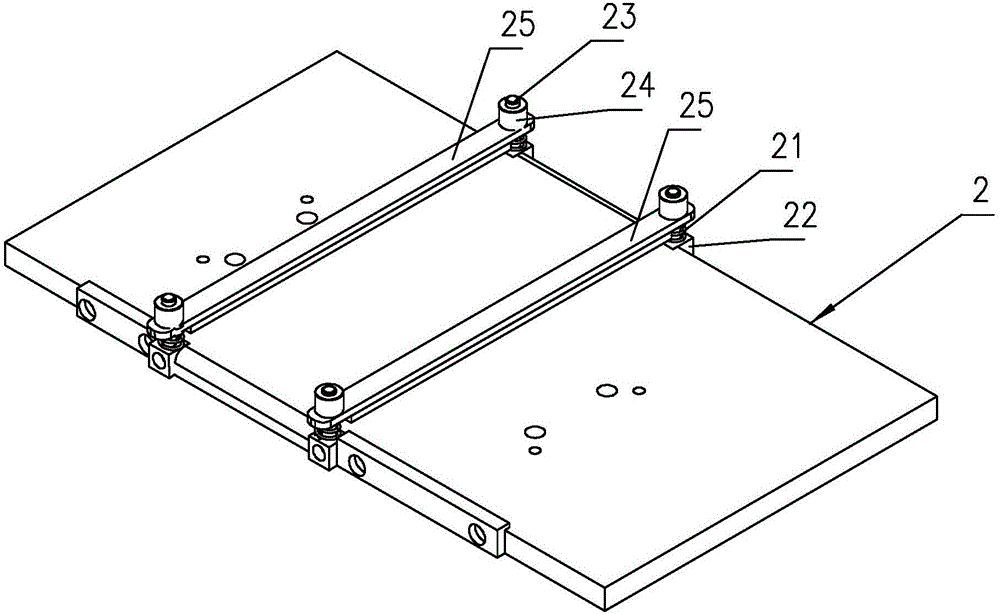

[0034] Such as Figure 1~5As shown, it is a fully automatic crystalline silicon solar cell quality testing machine of the present invention, which includes a box-type machine 1, an electric control device installed in the machine 1, a driving mechanism connected to the electric control device, and a machine set in the machine 1. The top surface is used to carry the detection table 2, the tape holder 3, the tape pressure wheel mechanism 4, the cutter 5 and the orientation adjustment mechanism for carrying the silicon wafer to be tested. 15 has a touch screen, and the control panel 15 is connected to the electric control device. On the inner side of the top surface of the machine table 1, a mounting plate 6 extending horizontally is provided, and a horizontal elongated through hole 61 is opened on the mounting plate 6. The table 2 passes through the elongated through hole 61, and a horizontal elongated hole 11 communicating with the inside of the machine table 1 is opened on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com