Display panel and display device

A display panel and flexible display technology, applied in the direction of identification devices, instruments, etc., can solve the problems of device layer damage of display modules, difficult restoration of flat state, large elastic modulus, etc., to achieve good bending display, strain reduction, The effect of improving bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

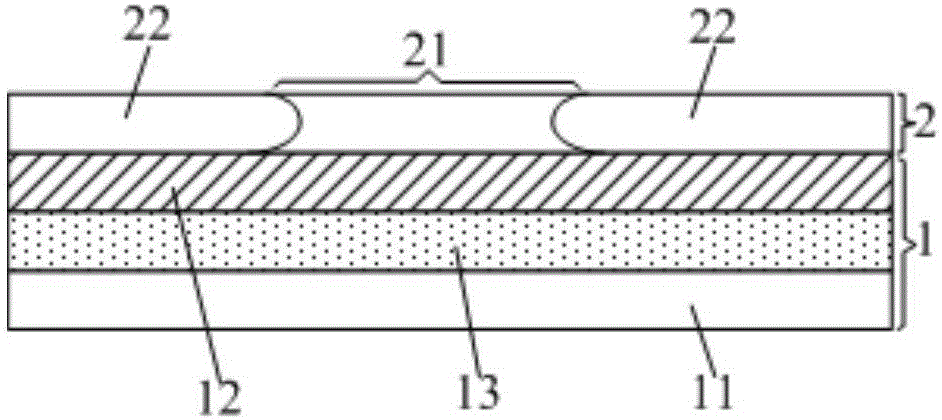

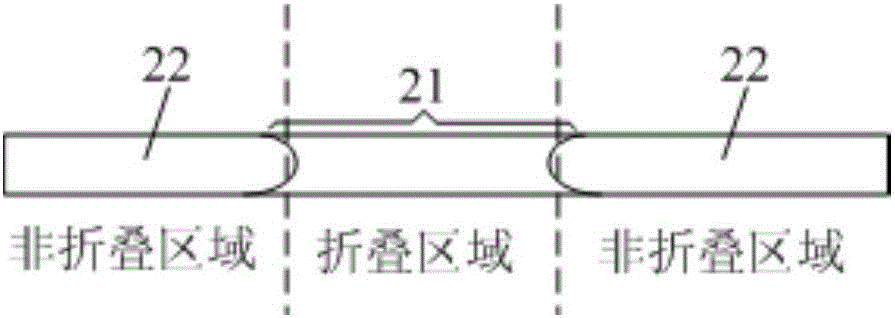

[0027] This embodiment provides a display panel, such as figure 1 and figure 2 As shown, it includes: a flexible display substrate 1 and a protective cover 2, the protective cover 2 is covered on the flexible display substrate 1, the protective cover 2 includes a flexible area 21, and the flexible area 21 is corresponding to the folding area of the flexible display substrate 1, The flexible region 21 is made of a material with an elastic modulus less than 100 MPa and a tensile strength greater than 50 MPa.

[0028] By making the flexible region 21 of the protective cover plate 2 adopt a material with an elastic modulus of less than 100 MPa and a tensile strength greater than 50 MPa, the neutral layer (that is, the film whose stress is 0 during the bending process) can be bent when the display panel is bent. layer) to the device layer in the flexible display substrate 1 (that is, the light-emitting device layer), so that the neutral layer is closer to the device layer in th...

Embodiment 2

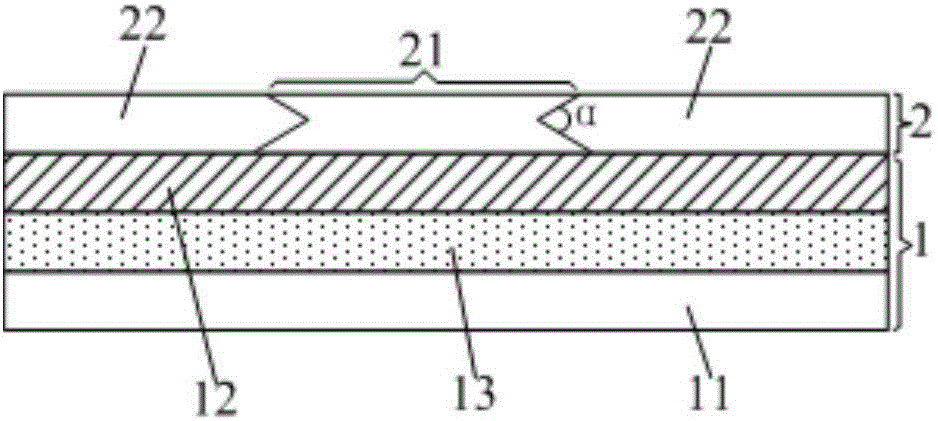

[0038] This embodiment provides a display panel, which is different from that in Embodiment 1, such as image 3 As shown, the butt surface of the flexible region 21 and the non-flexible region 22 is formed by splicing more than two planes, and the angle between any two adjacent planes is greater than 0°C and less than 180°C.

[0039]The joint surface formed by splicing two or more planes at a certain angle can disperse the stress of the flexible area 21 and the non-flexible area 22 in the joint area, so that the flexible area 21 and the non-flexible area 22 on the protective cover 2 The stress distribution in the butt joint area tends to be uniform, so that when the display panel is bent, the butt joint area will not cause damage to other film layers in the display panel.

[0040] Preferably, as image 3 As shown, the abutting surface of the flexible region 21 and the non-flexible region 22 is formed by splicing two planes, and the angle α between the two planes is greater th...

Embodiment 3

[0045] This embodiment provides a display device, including the display panel in Embodiment 1 or 2.

[0046] By using the display panel in Embodiment 1 or 2, the bending performance of the display device is improved, so that the display device can achieve better curved display.

[0047] The display device provided by the present invention can be any product or component with OLED display function, such as OLED panel, OLED TV, monitor, mobile phone, navigator, and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com