Hot rolling deformation resistance prediction method based on generalized additive model

A deformation resistance, model technology, used in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

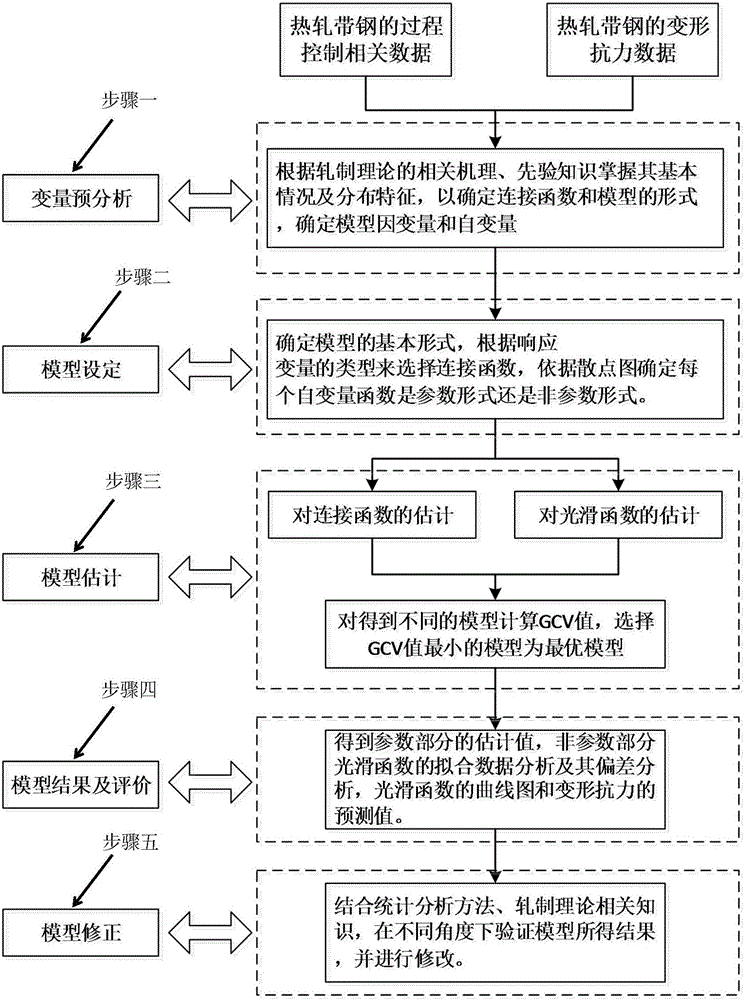

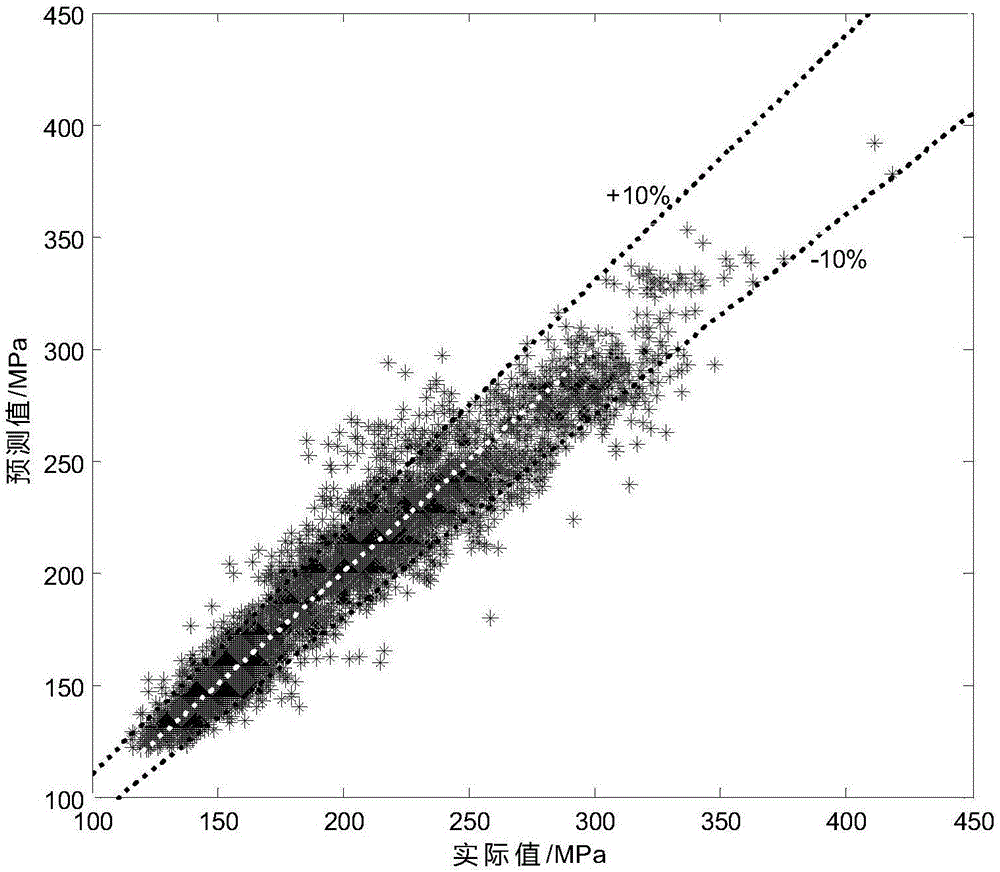

[0035] A method for predicting hot-rolled deformation resistance based on generalized additive models, which uses generalized additive models to quantitatively analyze the relationship between hot-rolled strip deformation resistance and its metal chemical composition and rolling conditions parameters, and establishes the hot-rolled strip The mathematical model of deformation resistance includes the following steps:

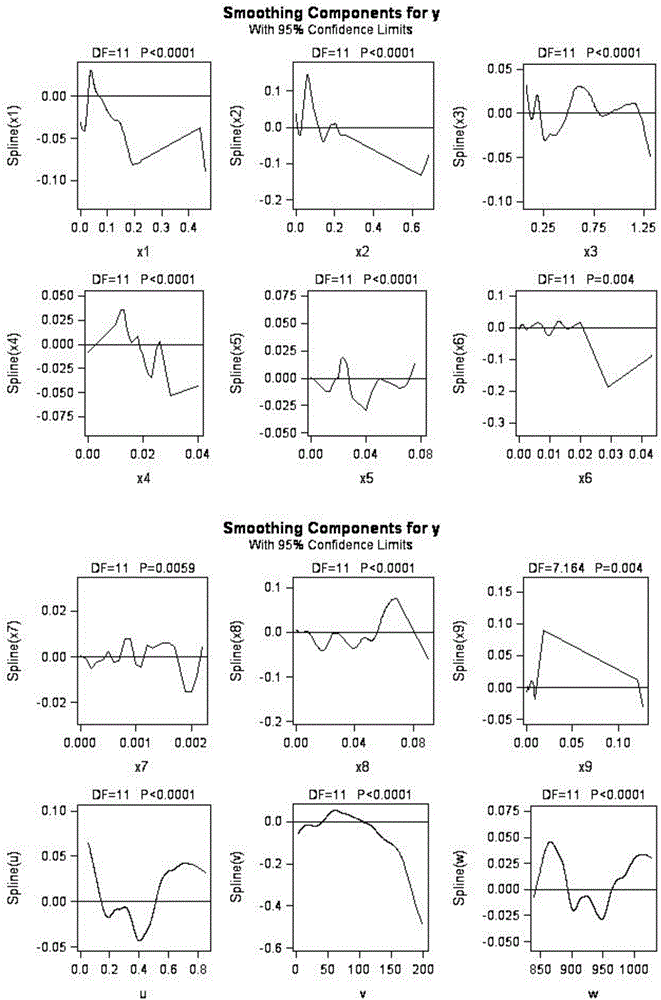

[0036] Step 1: Variable pre-analysis. The process data of hot-rolled strip deformation resistance is analyzed according to the research purpose, and the basic situation and distribution characteristics are mastered according to the relevant mechanism and prior knowledge of rolling theory, so as to determine the form of connection function and model; Deformation resistance model of strip steel, where the deformation resistance is taken as the dependent variable of the model, and the chemical composition of carbon, silicon, manganese, nickel, chromium, niobium, vana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com