Testing method of mass concentration of liquid water reducing agent

A technology of mass concentration and inspection method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large impact on concrete performance, large errors, and insensitivity to slight changes in the concentration of water reducing agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Instruments used in the present invention: analytical balance, weighing 200g, division value 0.0001g; blast electric heating constant temperature drying oven (1°C~200°C); 100ml evaporating dish; dryer, filled with color-changing silica gel.

[0008] Inspection steps:

[0009] 1. Put the clean evaporating dish into the oven, bake it at 100℃~105℃ for 30min, take it out and put it in the desiccator, after cooling for 30min, weigh it with the described one-ten-thousandth balance, repeat the above steps until the constant weight, Its mass is recorded as 1.

[0010] 2. Use a pipette to take 50ml of the sample to be tested and put it into an evaporating dish.

[0011] 3. Put the evaporating dish containing the sample into the oven, heat up to 100°C~105°C for drying, then place it in the desiccator to cool for 30 minutes, then weigh it with the above-mentioned one-ten-thousandth balance, repeat the above steps until Constant weight, its mass is recorded as 1.1.

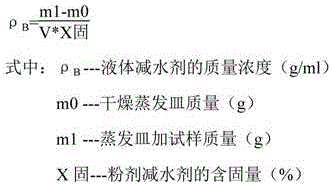

[0012] 4. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com