Rolling bearing fault on-line detection and state assessment method

A technology for rolling bearings and state assessment, which is applied in mechanical bearing testing, measuring devices, testing of mechanical components, etc., and can solve problems such as low efficiency and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

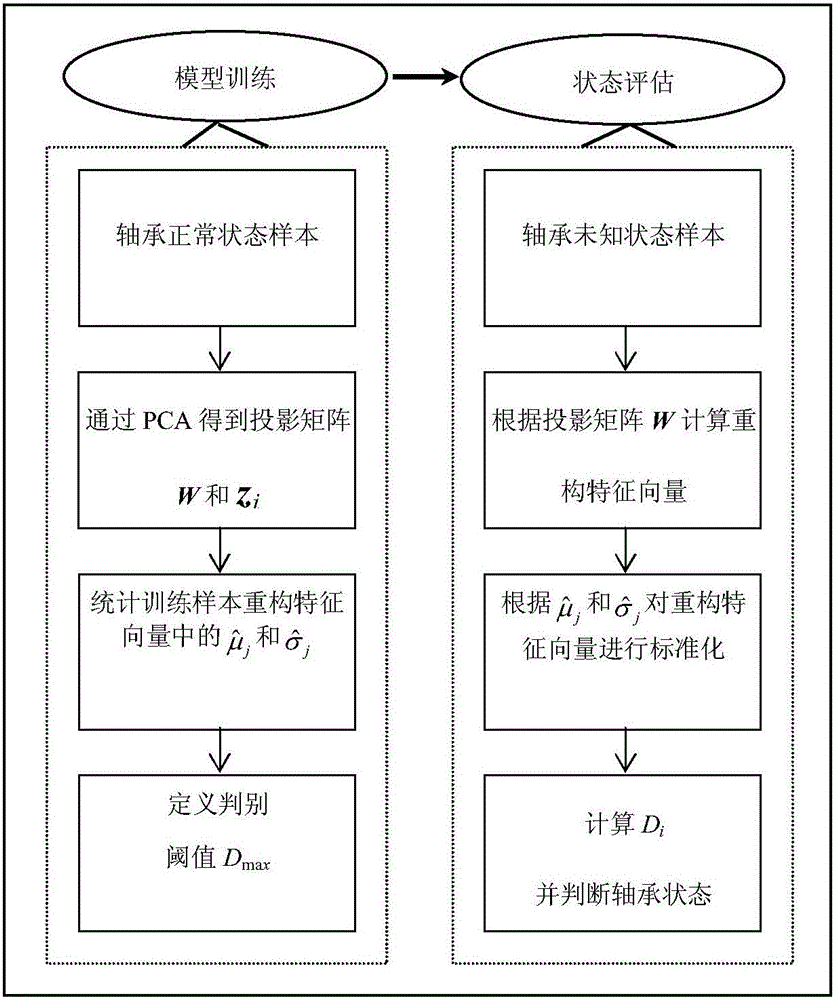

[0081] The content of a method for on-line fault detection and state evaluation of a rolling bearing according to the present invention will be further described below in conjunction with the accompanying drawings.

[0082] like figure 1 As shown, the present invention discloses a rolling bearing fault online detection and state evaluation method, which is specifically implemented according to the following steps:

[0083] S1: 12-dimensional dimensionless parameter extraction, specifically including the following four steps:

[0084] S1-1: Collect vibration acceleration signals, store the collected vibration acceleration signals in sections, and obtain several samples;

[0085] S1-2: Extract 6-dimensional time-domain statistical parameters through calculation of time-domain statistical parameters, including form factor T SI , peak index T CI , pulse index T MI , margin index T CLI , kurtosis T KU , skewness T SK ;

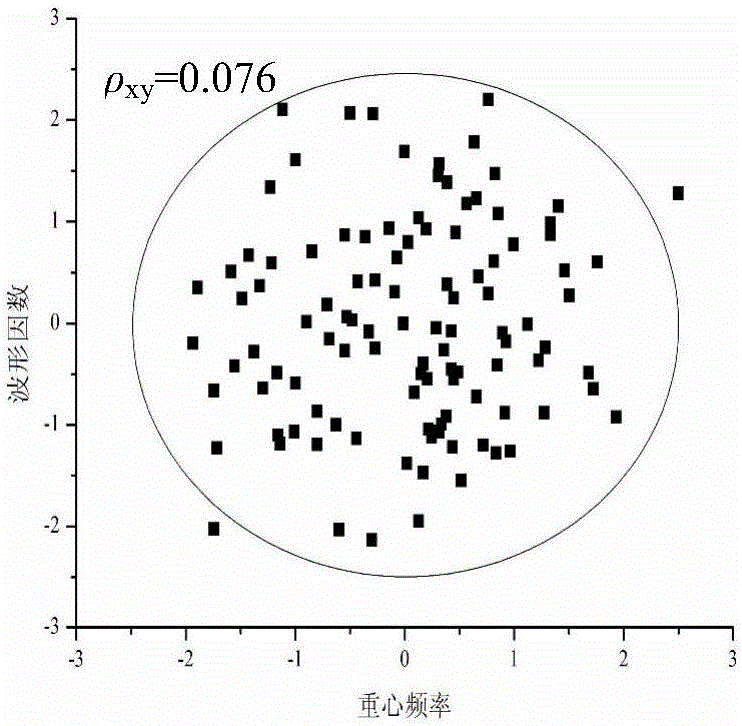

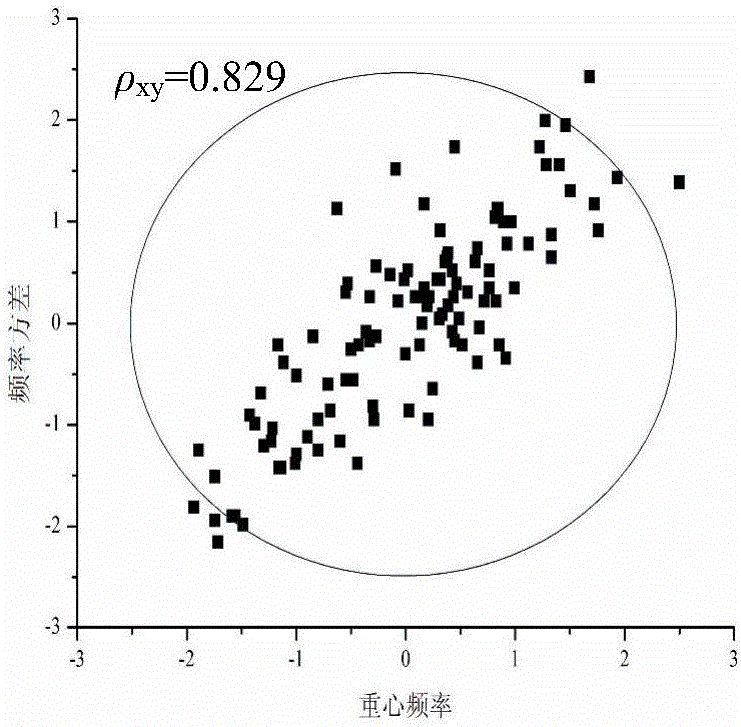

[0086] S1-3: Extract 3-dimensional time-domain statis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com