Heat recovering multi-split air conditioner and oil balancing control method thereof

A control method and heat recovery technology, applied in the multi-connected field, can solve the problems of increasing the cost of air conditioning, increasing the oil equalization pipeline, and the risk of system liquid seal, so as to improve installation efficiency, reduce installation operations, and eliminate system reliability problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

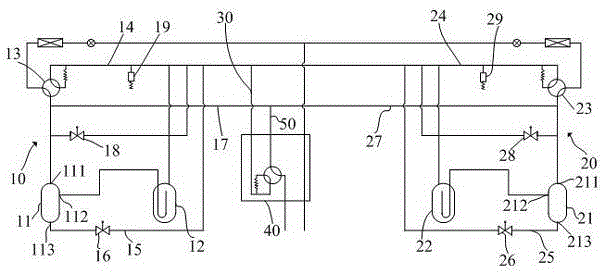

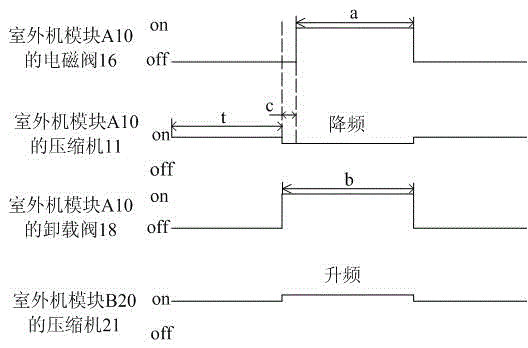

[0023] refer to figure 1 In this embodiment, a heat recovery multi-connection system is a three-pipeline heat recovery multi-connection system, including an indoor unit and two outdoor unit modules, that is, an outdoor unit module A10 and an outdoor unit module B20; the outdoor unit module A10 includes a compressor 11 , gas-liquid separator 12, four-way valve 13, low-pressure gas pipe 14 and controller, outdoor unit module B20 includes compressor 21, gas-liquid separator 22, four-way valve 23, low-pressure gas pipe 24 and controller; for each outdoor unit Module, taking the outdoor unit module A10 as an example, the exhaust port 111 of the compressor 11 is connected to the first valve port of the four-way valve 13, the air return port 112 is connected to the gas outlet 121 of the gas-liquid separator 12, and the low-pressure air pipe 14 The first end is connected to the second valve port of the four-way valve 13, and the connection relationship of each component of the outdoor...

Embodiment 2

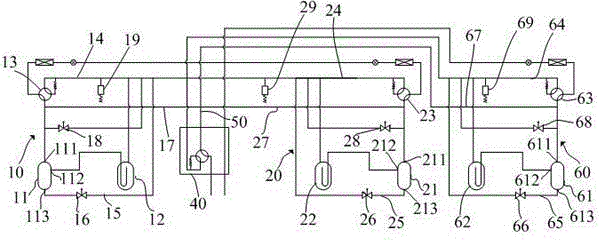

[0038] refer to image 3 , and the difference from Embodiment 1 is that in this embodiment, there are three outdoor unit modules of the three-pipeline heat recovery multi-line unit, that is, in addition to the outdoor unit module A10 and the outdoor unit module B20, the outdoor unit module C60 is also included, and the same , the outdoor unit module C60 includes a compressor 61, a gas-liquid separator 62, a four-way valve 63, a low-pressure air pipe 64, a controller and a high-pressure air pipe 67, and the exhaust port 611 of the compressor 61 is connected to the first port of the four-way valve 63. Valve port, the air return port 612 is connected to the gas outlet 621 of the gas-liquid separator 62, and the first end of the low-pressure air pipe 64 is connected to the second valve port of the four-way valve 63; Pipe 30 and low-pressure air pipe 64 are provided with a pressure sensor 69; the suction port 622 of the gas-liquid separator 62 is connected to the low-pressure air p...

Embodiment 3

[0053] The heat recovery multi-split system in this embodiment is a cooling-only heat recovery multi-split system, which is different from the three-pipeline heat recovery multi-split system described in Embodiments 1 to 3 in that it does not have high-pressure air pipes and simultaneous cooling and heating devices. refer to Figure 5 , when the cooling-only heat recovery multi-split unit includes an indoor unit and two outdoor unit modules, that is, the outdoor unit module A10 and the outdoor unit module B20, the specific structure is the same as that in Embodiment 1, that is, the outdoor unit module A10 includes a compressor 11, a gas Liquid separator 12, four-way valve 13, low-pressure air pipe 14 and controller, outdoor unit module B20 includes compressor 21, gas-liquid separator 22, four-way valve 23, low-pressure air pipe 24 and controller; for each outdoor unit module, Taking the outdoor unit module A10 as an example, the exhaust port 111 of the compressor 11 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com