Steel cylinder concrete top pipe and connecting method thereof

A technology of steel cylinder concrete and connection method, which is applied in the direction of pipe/pipe joint/pipe fitting, pipe, rigid pipe, etc., can solve the problems of affecting the sealing performance of the interface, the influence of the surrounding soil around the pipe, and the uneven grouting, etc. The effect of small inner layer reinforcement, reducing the top force and strengthening the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

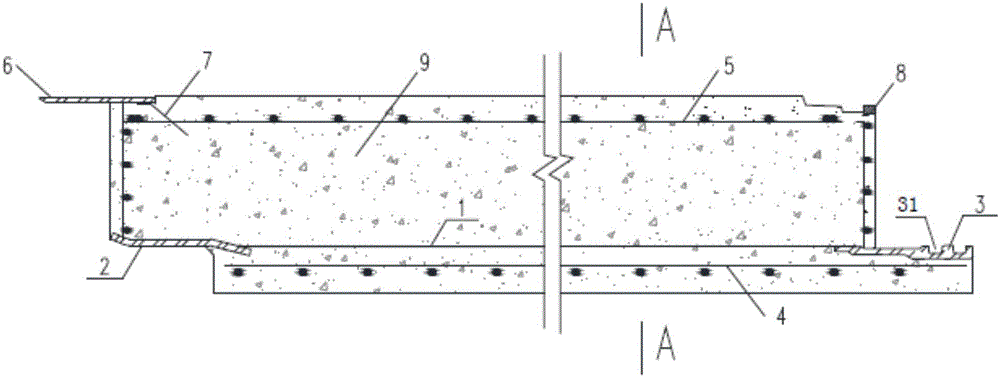

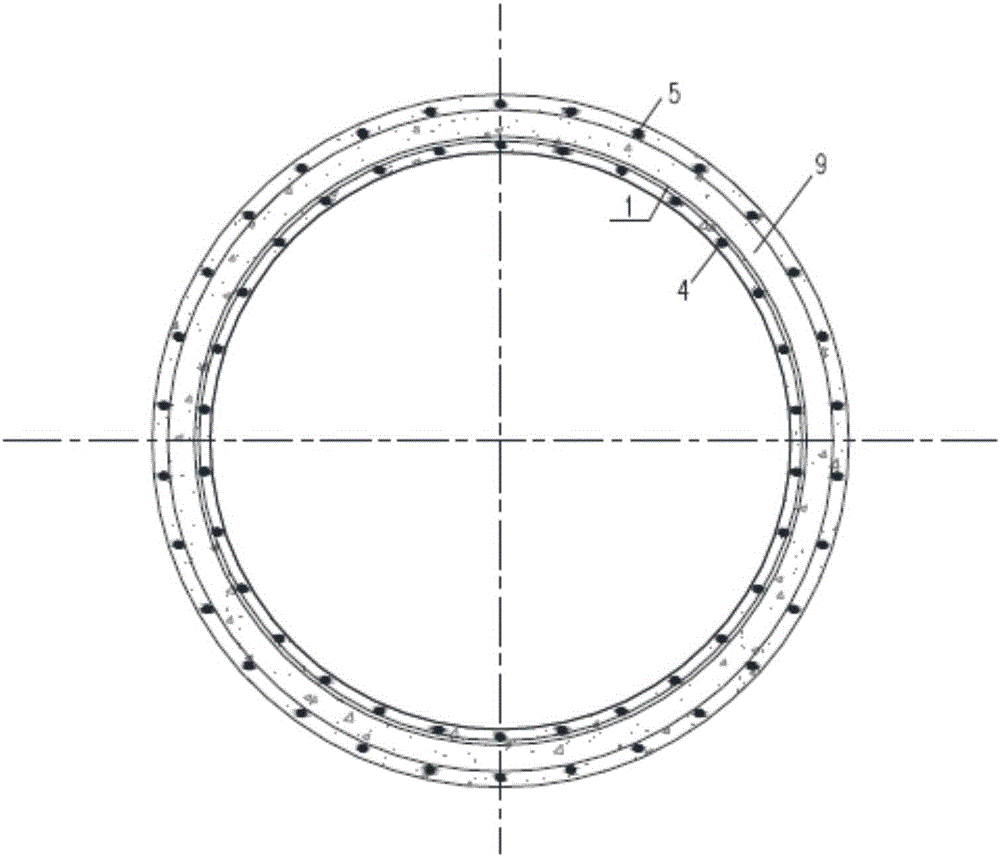

[0020] Please refer to Figure 1-3 , the present embodiment 1 provides a steel cylinder concrete pipe jacking, which sequentially includes an inner steel mesh 4, a steel cylinder 1, a tube core concrete 9, and an outer layer steel mesh 5 from the inside to the outside, and the two ends of the steel cylinder 1 are respectively fixed Connected with the socket 2 and the socket 3, it also includes an outer steel sheath 6 fixedly arranged on the outer steel mesh 5, the outer steel sheath 6 is located on the outer side of the end of the socket 2, and the outer steel sheath 6 The sleeve 6 is anchored and connected to the pipe core concrete 9 through the outer steel mesh 5 through the anchor bar 7, and the socket 3 is provided with two groups of grooves 31 apart from each other, and the grooves 31 are close to the end of the socket. Set, each group of grooves 31 is embedded with an "O"-shaped sealing ring 10, and the outer layer of steel mesh 5 located on the end face side of the sock...

Embodiment 2

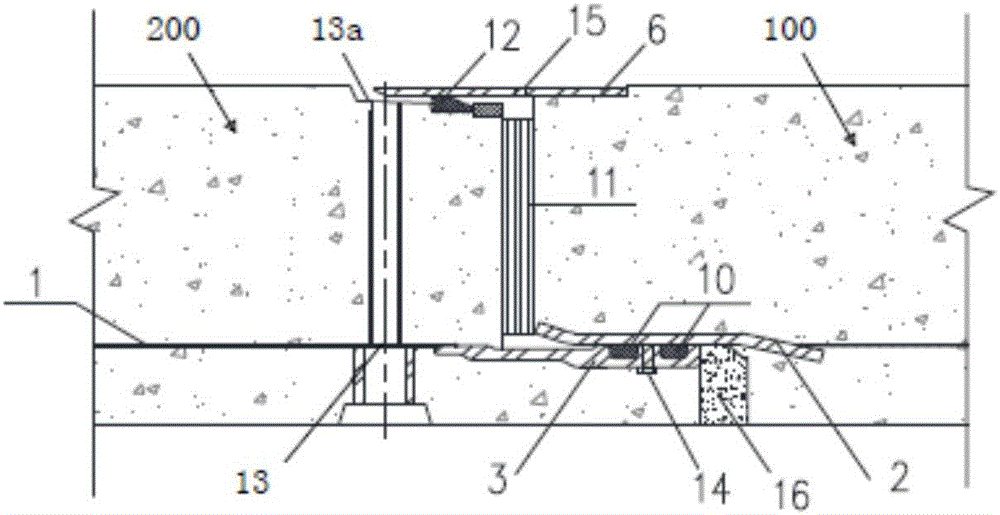

[0028] This embodiment 2 provides a connection method for steel cylinder concrete pipe jacking based on implementation 1, using two sections of steel cylinder concrete pipe jacking in embodiment 1, including the first steel cylinder concrete pipe jacking 100 and the second steel cylinder concrete pipe jacking Pipe 200; install a wooden liner 11 at the end of the socket 2 of the first steel cylinder concrete jacking pipe 100, and push the socket 3 of the second copper cylinder concrete jacking pipe 200 into the first The socket 2 of the steel cylinder concrete jacking pipe 100; through the "O"-shaped sealing ring 10, a seal is formed between the socket 3 of the second copper cylinder concrete jacking pipe 200 and the socket 2 of the first steel cylinder concrete jacking pipe 100 Connection: through the wedge-shaped sealing ring 12, the outer steel mesh 5 of the second steel cylinder concrete jacking pipe 200 and the outer steel casing 6 of the first copper cylinder concrete jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com