Dual-redundancy electric steering engine

An electric steering gear and dual redundancy technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of unable to use high-power motors, objects controlled by steering gears, and limited multi-level output power, etc. Linear motion performance, improved reliability, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

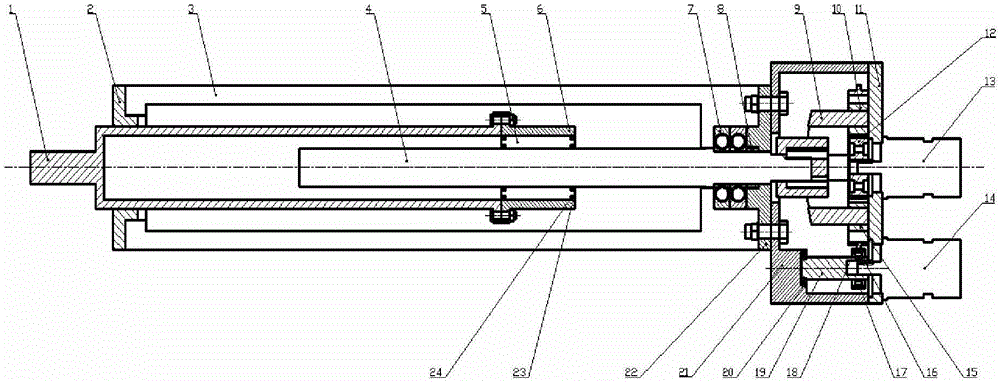

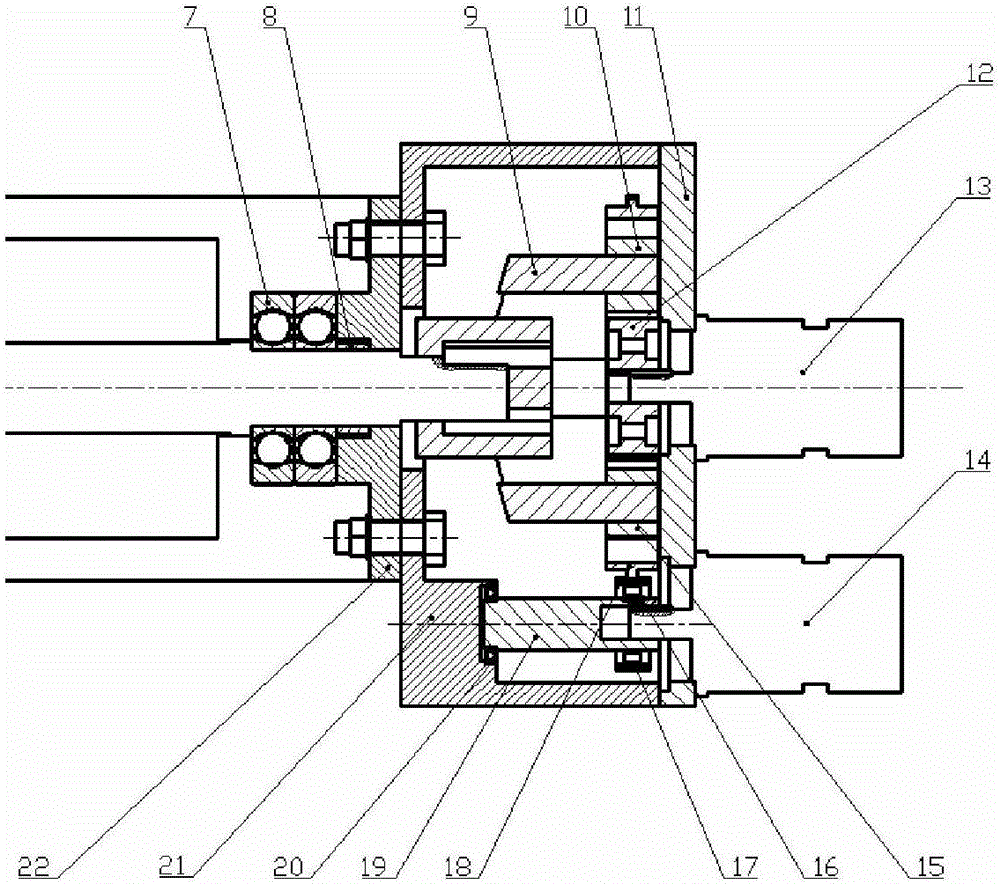

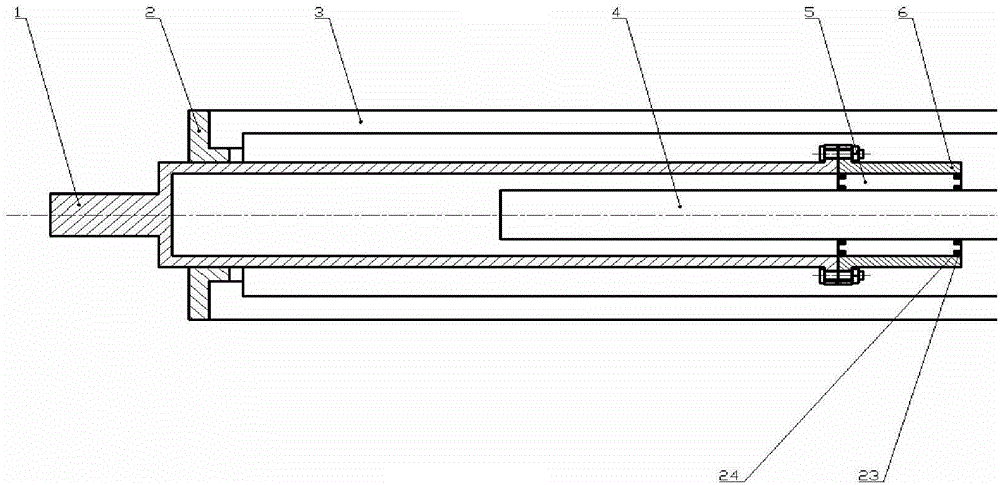

[0025] In flight control, the electric steering gear system is mostly in the frequent real-time working state, especially under the condition of high frequency and high aerodynamic load, in order to prevent the motor in the electric steering gear Loss of control threatens the safety of the aircraft and pilots, causing unnecessary losses; at the same time, in order to install electric steering gear with a larger power range in the narrow steering gear installation space of the aircraft, the power range of the flight control system is widened, and the system’s performance is improved. Reliability, this example further elaborates on the dual redundancy electric steering gear.

[0026] refer to Figure 1 to Figure 7 In this example, the double-redundancy electric steering gear consists of a planetary gear transmission reduction mechanism, a planetary roller screw pair, a sleeve push rod 1, an actuator end cover 2, a housing 3, a reducer rear cover 11, and a reducer shell body 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com